Flexible self-supporting porous electrode, preparation method thereof and application thereof

A porous electrode, self-supporting technology, used in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, etc., can solve the problems of hindered ion and electron transport, poor capacity, etc., and is conducive to wetting and ion transport. Energy density, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

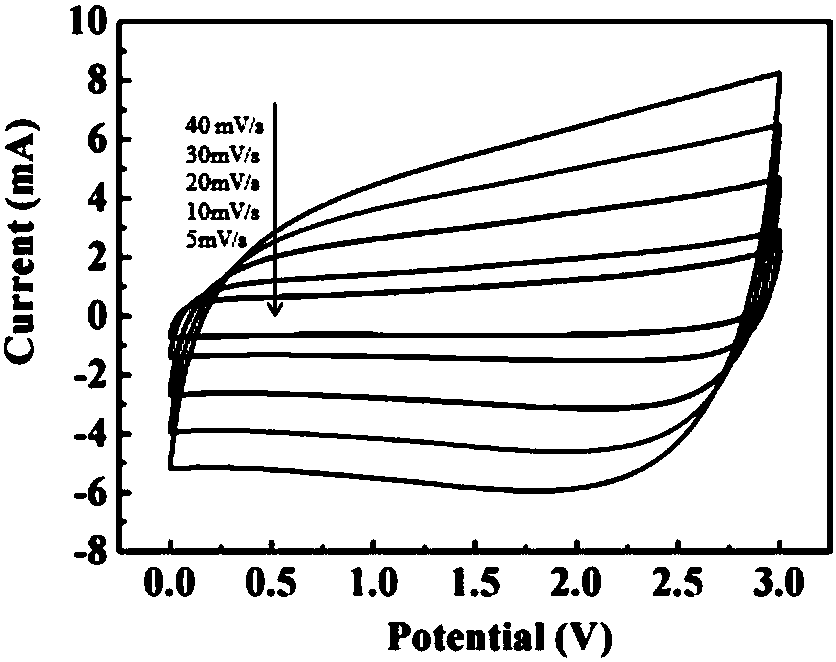

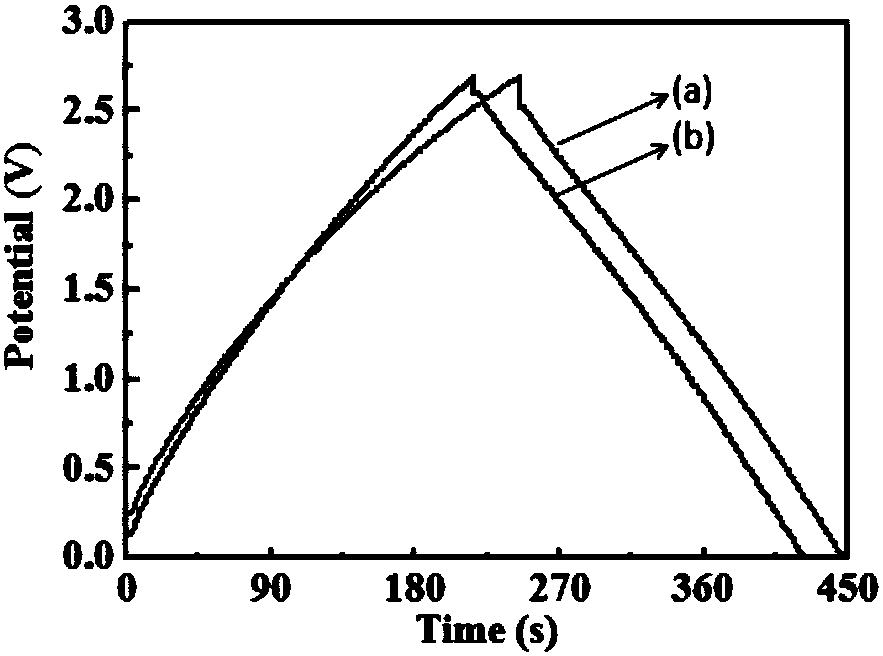

[0035] Dissolve 0.44g of PVDF-HFP in 31g of N-methylpyrrolidone (NMP), stir until it is completely dissolved, add 0.55g of Super P, stir for 10min, then add 4.5g of activated carbon, stir for 4h to form a uniform slurry, adjust with a scraper To 400μm, scrape the electrode on the glass plate, then place the glass plate in water, after the electrode is separated from the glass plate, freeze the electrode in the refrigerator for 12 hours, and dry it in a freeze dryer for 12 hours to obtain Electrodes with a porous structure, such as attached figure 1 shown. Finally weighed, after vacuum drying at 60°C for 24 hours, punched into electrode pieces with a diameter of 14mm and assembled into a symmetrical supercapacitor, in which both the positive and negative electrodes were prepared electrodes, the diaphragm was celgard2400, and the electrolyte was 1mol / L Tetraethylammonium tetrafluoroborate / propylene carbonate.

[0036] In the glove box, the electrode sheets were assembled into ...

Embodiment 2

[0040] Example 2: Dissolve 0.44g of PAN in 31g of N-methylpyrrolidone (NMP), stir until completely dissolved, add 0.55g of Super P, stir for 10min, add 4.5 g of activated carbon, stir for 4h to make a uniform slurry. Others are the same as in Example 1.

Embodiment 3

[0041] Example 3: Dissolve 0.44g of PAN in 31g of N-methylpyrrolidone (NMP), stir until completely dissolved, add 0.55g of Super P, stir for 10min, then add 4.5g of carbon nanotubes, stir for 4h to make a uniform slurry. Others are the same as in Specific Embodiment 1-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com