A simple air intake device and air intake method for superplastic forming/diffusion connection

A technology of diffusion bonding and superplastic forming, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as difficulty in process research, inhalation of air oxidation, etc., and achieve low cost, good sealing, and strong pressure resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

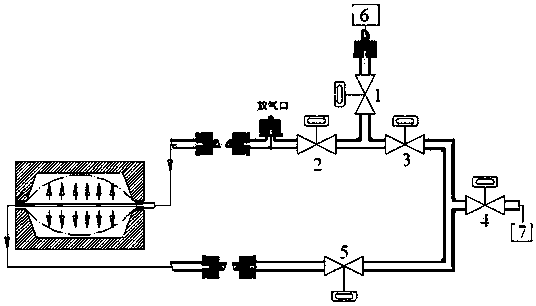

[0024] Such as figure 1 As shown, a simple air intake system for superplastic forming / diffusion connection, including a first two-way valve 1, a second two-way valve 2, a third two-way valve 3, a fourth two-way valve 4, a fifth two-way valve 5, four Spherical seal joint, vacuum system 7, air source system 6 components. The first two-way valve 1, the second two-way valve 2, and the third two-way valve 3 are connected together by a three-way pipe, wherein the first two-way valve 1 is connected to the air source system 6 to realize the cutting and opening of the air source; the second two-way valve 2. Control the washing, vacuuming and inflating functions of the outer layer of the molded parts; the third two-way valve 3 is used as a cut-off valve for the inner and outer layers to work independently; the fourth two-way valve 4 is connected to the vacuum system 7, which is the opening and closing of the vacuum system 7 The main control valve is connected with the inner layer of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com