Focus point control laser welding method

A technology of laser welding and focus, which is applied in the direction of laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of reducing welding penetration, laser energy density, and weld penetration, etc., to achieve compensation for dimensional tolerances and improve Tolerance, the effect of increasing penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

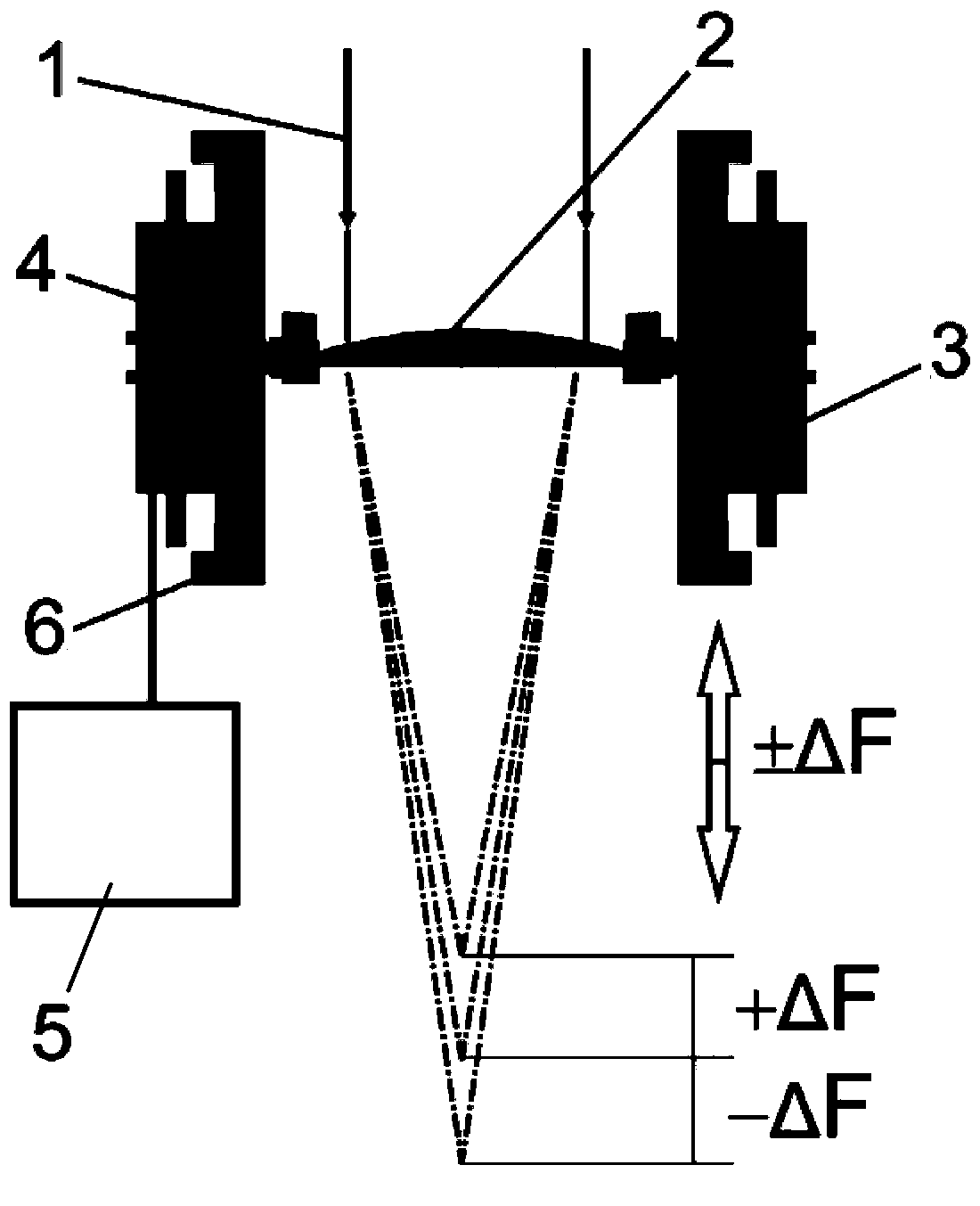

[0028] Nd:YAG continuous laser is used for laser welding of 00Cr17Ni14Mo2 steel with a thickness of 6mm. The laser power is 4kW, the welding speed is 72m / h, and the defocus of the focus balance position is -1.2mm. image 3 Middle a is the cross-sectional view of the focus vertical vibration laser welding joint, the vertical vibration frequency is 500Hz, the amplitude is 1.5mm, and the diameter of the filler wire is 1mm; image 3 Middle b is the cross-sectional view of laser welded joints without vertical vibration and lateral swing in focus. In both cases it can be seen that in the case of focal vertical vibration laser welding the penetration depth increases, indicating an increased absorption of the laser light by the steel.

Embodiment 2

[0030] Nd:YAG continuous laser is used to laser weld 1560 aluminum alloy with a thickness of 5mm. The laser power is 2.5kW, the welding speed is 60m / h, and the defocus of the focus balance position is -2mm. Figure 4 Middle a is the cross-sectional view of the laser welded joint without vertical vibration and lateral swing at the focal point; Figure 4 Middle b is the cross-sectional view of the laser welded joint with the vertical vibration and lateral vibration of the focal point. The lateral vibration frequency is 50 Hz, the swing amplitude is 1 mm, and the vertical vibration frequency is 500 Hz, and the amplitude is 1.5 mm. In two cases it can be seen that Figure 4 The penetration depth of the joint in a is less than Figure 4 The penetration depth of the joint in b shows that for aluminum alloys, reasonable adjustment of the frequency and amplitude of the vertical vibration and lateral oscillation of the focus is conducive to improving the penetration depth.

Embodiment 3

[0032] Nd:YAG continuous laser is used for laser welding of 8mm thick TC4 titanium alloy, the laser power is 4kW, and the welding speed is 30m / h. Figure 5 Middle a is the cross-sectional view of the laser welded joint with vertical vibration and lateral oscillation of the focal point. The vertical vibration frequency of the focal point is 500Hz, the amplitude is 1.5mm, the lateral oscillation frequency is 30Hz, and the oscillation amplitude is 1.5mm; Figure 5 Middle b is the cross-sectional view of the laser-welded joint without vertical vibration and lateral swing at the focal point. It can be seen in both cases that the depth of penetration increases in the case of laser welding with focal vertical oscillation and lateral oscillation, indicating an increase in the absorption rate of the laser light by the titanium alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com