Sewage Treatment Process

A sewage treatment and process technology, applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of inability to reduce stirring speed and complicated process, and achieve better flocculation effect. Good, good water purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

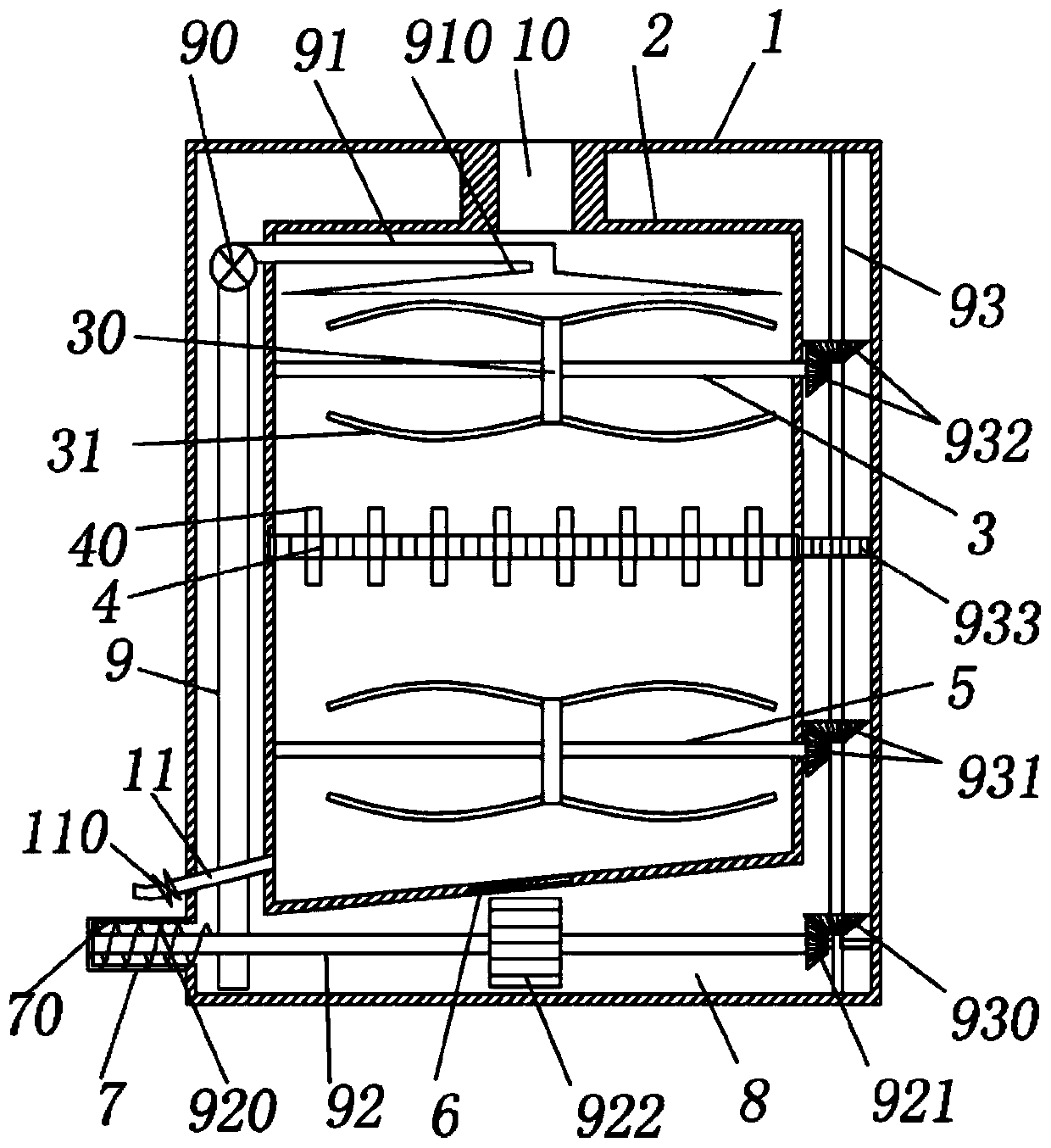

[0028] The embodiment is basically as attached figure 1 Shown:

[0029] The sewage treatment process adopts a coagulation machine for coagulation treatment, and the coagulation machine includes an outer bucket 1, an inner bucket 2 and a medicine bucket 7.

[0030] A water injection pipe 10 , a drain pipe 11 and an interlayer 8 are arranged between the outer tub 1 and the inner tub 2 . The water injection pipe 10 is located at the top of the outer barrel 1 and the inner barrel 2; the drain pipe 11 is located at the bottom of the outer barrel 1 and the inner barrel 2, and the drain pipe 11 is provided with a drain valve 110 .

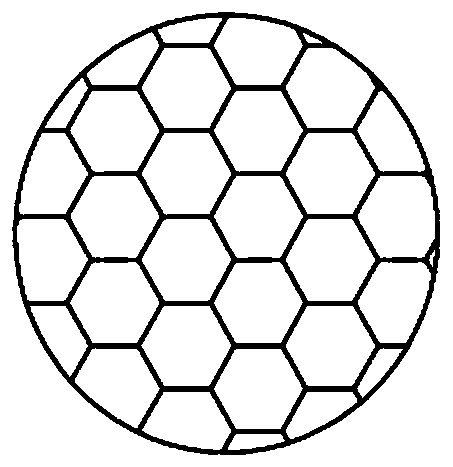

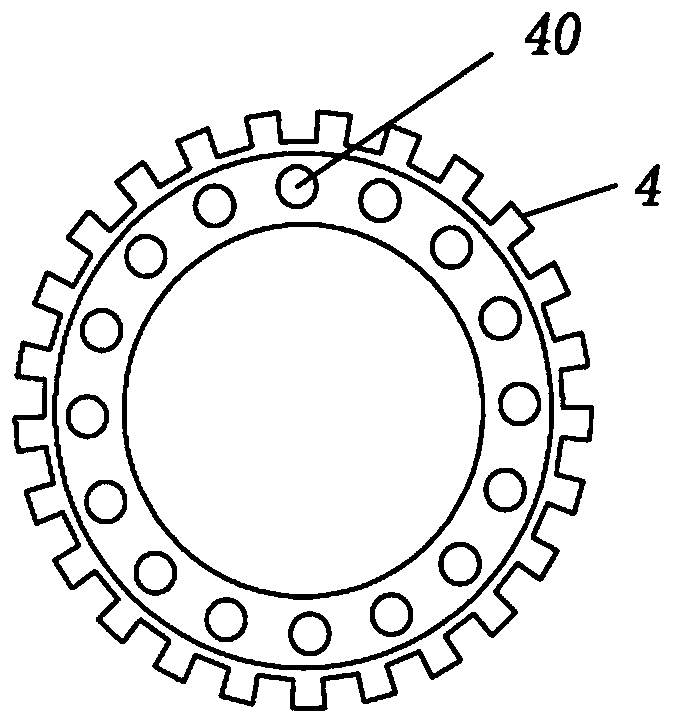

[0031] The inner barrel 2 is provided with an upper stirring rod 3 , a middle stirring part and a lower stirring rod 5 . Both the upper stirring rod 3 and the lower stirring rod 5 are provided with a plurality of arc-shaped blades 31 . In this embodiment, each stirring rod is provided with four arc-shaped blades 31 , which are symmetrical left and righ...

Embodiment 2

[0041] The difference between this embodiment and embodiment 1 is: in step A, the coagulant includes 20kg aluminum sulfate and 5kg polyaluminium chloride by mass; in step B, the volume of sewage accounts for 9 / 10 of the volume of the inner barrel; The time is 10 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com