Device and process for treating waste mineral oil

A technology of waste mineral oil and treatment equipment, which is applied in the direction of multi-stage series refining process treatment, etc., can solve the problems of waste mineral oil, such as the thoroughness to be improved, irregularities, etc., to avoid leakage, low distillation pressure, and solve polluted products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

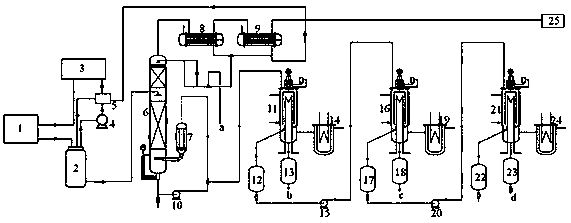

[0030] This embodiment is used to illustrate the waste mineral oil treatment device and process of the present invention.

[0031] Such as figure 1 As shown, the waste mineral oil treatment device includes a filtration precipitation device 1, a raw material storage tank 2, a water treatment device 3, a storage tank vacuum pump 4, an oil-water separator 5, a vacuum thin film evaporator 6, a first molecular still 11, a second molecular still 16 and a third molecular still 21.

[0032] The oil discharge pipe of the filter sedimentation device 1 is connected to the raw material storage tank 2, and its sewage discharge pipe is connected to the water treatment device 3. The raw material storage tank 2 is connected to the feed port of the vacuum thin film evaporator 6 through the oil discharge pipe, and the raw material storage tank 2 is passed through The tank vacuum pump 4 is connected with the oil-water separator 5, and the oil-water separator 5 is connected with the water treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com