Urea production waste liquid treatment device and treatment method

A waste liquid treatment, urea technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as waste of water resources, environmental pollution, high treatment costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

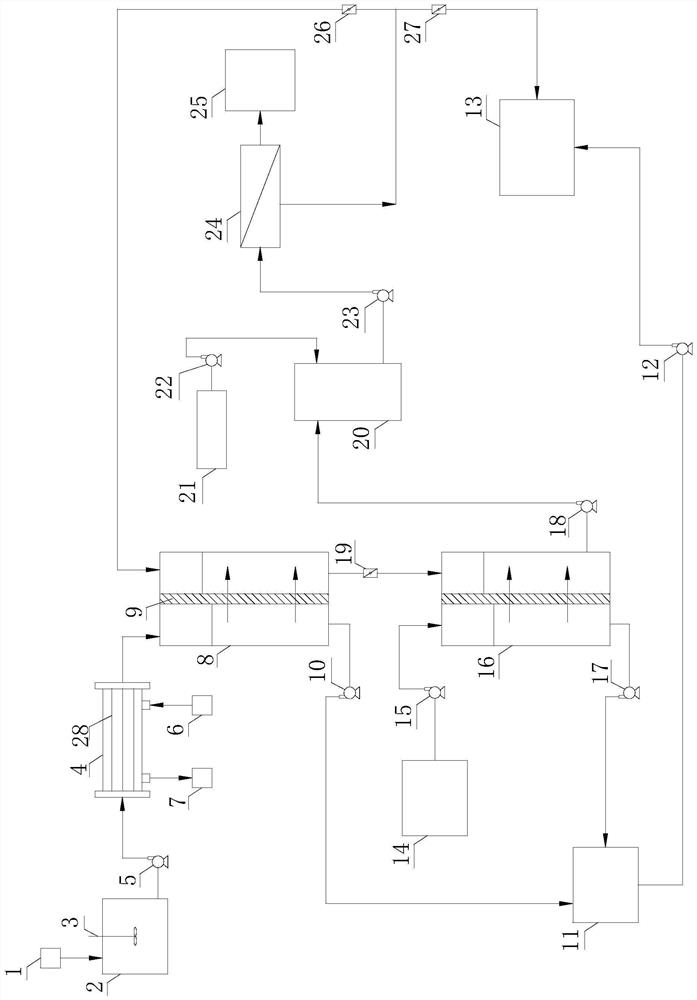

[0052]A urea production waste liquid treatment device, comprising a conversion condensate collection tank 2 and a urea analysis waste liquid collection tank 14, the conversion condensate collection tank 2 passes through the inlet of the ammonia nitrogen removal unit, the forward osmosis unit and the water tank 20 of the desalination station The desalted water inlet of the water tank 20 of the desalted water station is connected with the desalted water purification station 21, the outlet of the water tank 20 of the desalted water station is connected with the inlet of the reverse osmosis device 24, and the water production side of the reverse osmosis device 24 is connected with the desalted water production tank 25 . Described ammonia nitrogen removal unit is hydrophobic porous membrane device 4, and the inside of hydrophobic porous membrane device 4 is provided with hollow fiber membrane 28, and the material of hollow fiber membrane 28 is polytetrafluoroethylene; The condensat...

Embodiment 2

[0065] A urea production waste liquid treatment device, comprising a conversion condensate collection tank 2 and a urea analysis waste liquid collection tank 14, the conversion condensate collection tank 2 passes through the inlet of the ammonia nitrogen removal unit, the forward osmosis unit and the water tank 20 of the desalination station The desalted water inlet of the water tank 20 of the desalted water station is connected with the desalted water purification station 21, the outlet of the water tank 20 of the desalted water station is connected with the inlet of the reverse osmosis device 24, and the water production side of the reverse osmosis device 24 is connected with the desalted water production tank 25 . Described ammonia nitrogen removal unit is hydrophobic porous membrane device 4, and the inside of hydrophobic porous membrane device 4 is provided with hollow fiber membrane 28, and the material of hollow fiber membrane 28 is polytetrafluoroethylene; The condensa...

Embodiment 3

[0078] A urea production waste liquid treatment device, comprising a conversion condensate collection tank 2 and a urea analysis waste liquid collection tank 14, the conversion condensate collection tank 2 passes through the inlet of the ammonia nitrogen removal unit, the forward osmosis unit and the water tank 20 of the desalination station The desalted water inlet of the water tank 20 of the desalted water station is connected with the desalted water purification station 21, the outlet of the water tank 20 of the desalted water station is connected with the inlet of the reverse osmosis device 24, and the water production side of the reverse osmosis device 24 is connected with the desalted water production tank 25 . Described ammonia nitrogen removal unit is hydrophobic porous membrane device 4, and the inside of hydrophobic porous membrane device 4 is provided with hollow fiber membrane 28, and the material of hollow fiber membrane 28 is polytetrafluoroethylene; The condensa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com