Mo-Nb-Ta-Zr-Hf high-entropy alloy and preparation method thereof

A high-entropy alloy and alloy technology, applied in the field of MoNbTaZrHf high-entropy alloy and its preparation, can solve the problems of emphasis, lack of high hardness, corrosion resistance, high temperature resistant alloy material, single performance, etc., and achieve broad application prospects, excellent Corrosion resistance, effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

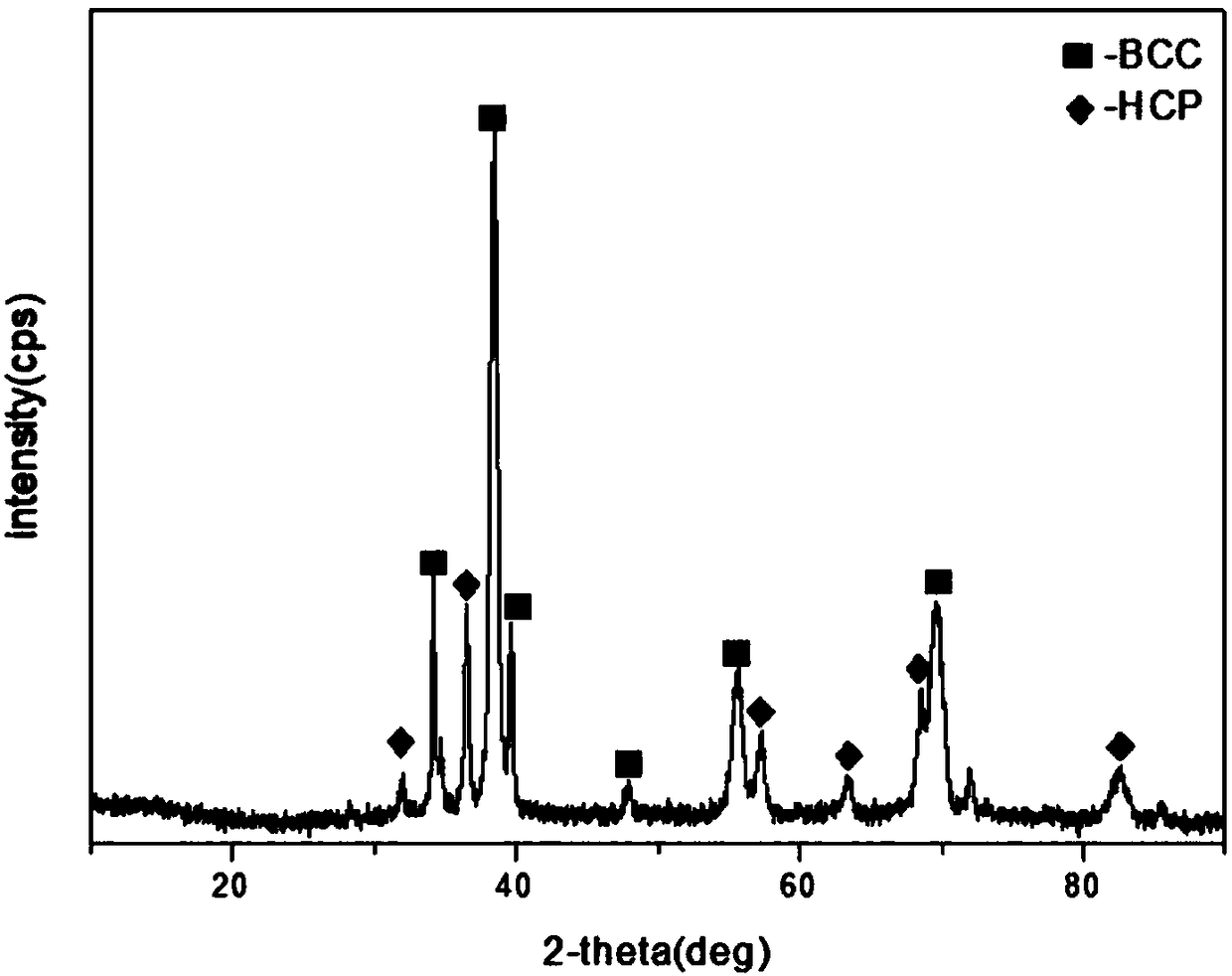

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples, so that those skilled in the art can better understand the present invention and implement it, but the given examples are not intended to limit the present invention.

[0021] One, a kind of MoNbTaZrHf high-entropy alloy, the component of this high-entropy alloy is Mo a Nb b Ta c Zr d f e , wherein, the molar ratio of each element a:b:c:d:e=1:1:1:1:1; the mass fraction percentage content of materials such as Mo, Nb, Ta, Zr, Hf, Ti that adopts The purity is above 99.7%.

[0022] Two, a kind of preparation method of MoNbTaZrHf high-entropy alloy comprises the following steps:

[0023] (1) Ultrasonic treatment: After adding acetone to submerge the material in the container, ultrasonically clean it for 15-20 minutes to remove oil and impurities attached to the metal surface; then Mo, Nb, Ta, Zr, Hf, and Ti materials after removing impurities are separated Put it in a container...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com