Detonator startup hydraulic setting tool and application thereof

A technology of hydraulic setting and detonator, which is applied in the fields of production fluid, wellbore/well components, earth-moving drilling, etc. It can solve the problems of inconvenient setting, high cost, customized processing of gunpowder column, etc., so as to facilitate on-site flexible organization The effect of convenient construction, storage and transportation, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

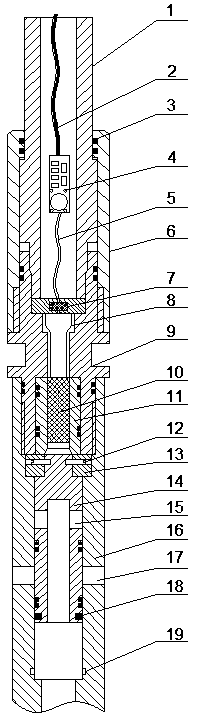

[0034] This embodiment provides a detonator activated hydraulic setting tool, which includes an electronic control mechanism, a detonator activation mechanism, a hydraulic transmission mechanism and a power actuator connected in sequence from top to bottom.

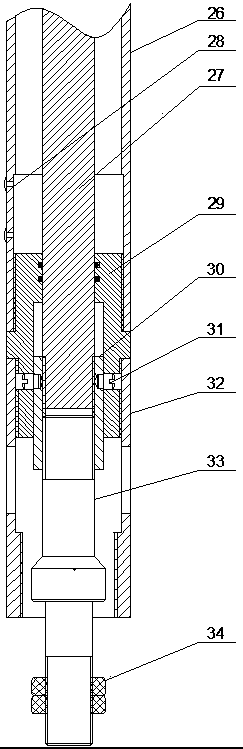

[0035] The electronic control mechanism receives the starting signal from the ground, and the detonator starting mechanism detonates the detonator according to the starting signal, cuts the starting shear nail, pushes the piston to a predetermined position, and connects the hydraulic transmission channel. The hydraulic transmission mechanism is used to transmit the hydraulic pressure in the wellbore to the sheath In the gap with the center tube, due to the different force-bearing areas at both ends of the sheath, an upward driving force is generated to make the sheath and the connecting rod move relative to each other. The power actuator is used to connect the central part and the outer part of tools such as bridge plugs re...

Embodiment 2

[0038] On the basis of Example 1, such as figure 1 or Figure 4As shown, the electronic control mechanism includes a cable protection tube 1 and a joint 6 connected up and down, and the axial cavity formed by the cable protection tube 1 and the joint 6 is provided with a cable 2 and an electronic control circuit that are electrically connected in sequence from top to bottom. 4. Signal line 5. The electronic control circuit 4 is used to receive the starting electric signal from the ground, and the starting electric signal is decoded by the electronic control circuit 4 to generate a starting signal of a specific frequency, which is transmitted to the detonator starting mechanism through the signal line 5 .

Embodiment 3

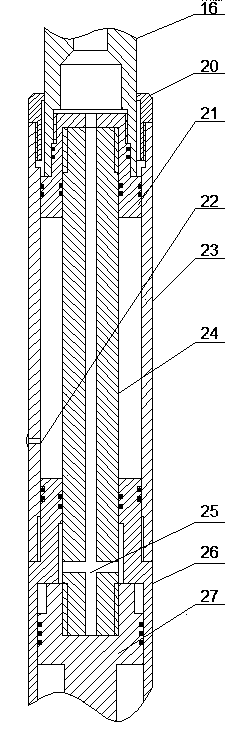

[0040] On the basis of Example 1, such as figure 1 or Figure 4 As shown, the detonator starting mechanism includes a connecting joint 9 and a piston cylinder 16 connected up and down, the connecting joint 9 is connected with the cable protection tube 1 and the joint 6, and the igniter 7 and the nonel are installed in the connecting joint 9 sequentially from top to bottom. 8. The detonator 10, the igniter 7 are electrically connected with the signal line 5, and the protective cover 11 is installed outside the detonator 10; the piston 14 is installed in the piston cylinder 16, and the piston 14 is fixed on the pressure ring 13 through the starting pin 12, and the pressure ring 13 is installed on the inner wall of the piston cylinder 16 at the joint between the piston cylinder 16 and the connecting joint 9, the inside of the piston 14 is hollow, and the inner liquid inlet hole 15 is opened on the wall, and the outer liquid inlet hole 17 is opened on the wall of the piston cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com