Diaphragm-free static zinc-bromine battery

A zinc-bromine battery without diaphragm technology, which is applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of large internal resistance of the battery, and achieve the effects of reducing battery cost, simple system structure, and reducing system loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

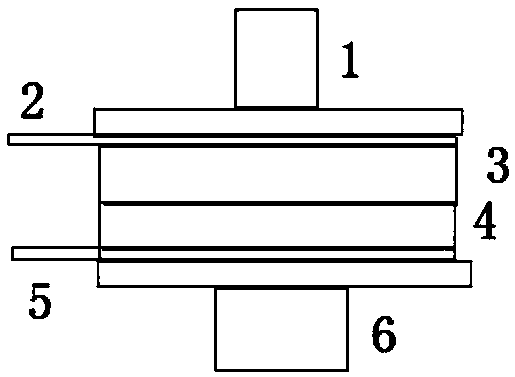

[0028] Battery assembly:

[0029] The positive electrode uses carbon felt with a size of 4x4x0.5cm, and the negative electrode uses a graphite plate with a size of 6.5x 6.5x0.2cm. The electrolyte is 2MZnBr 2 +3MKCl+0.4M MEP.

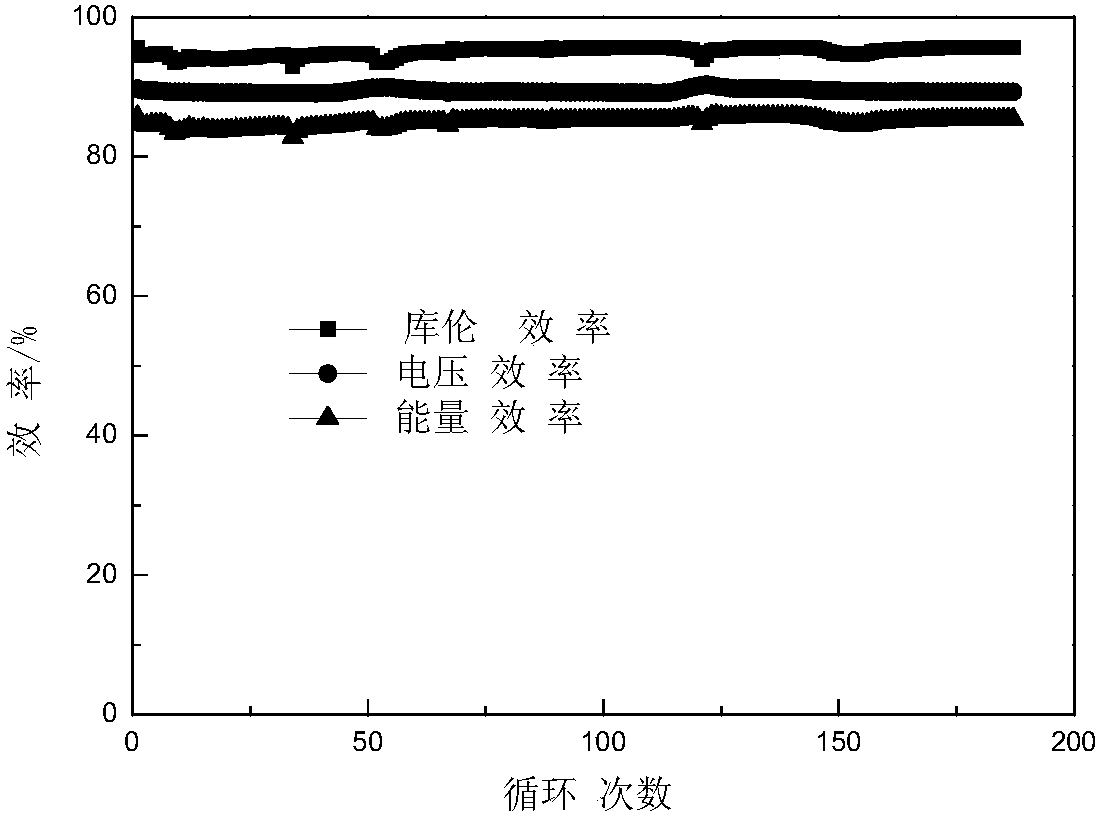

[0030] The single cell sequentially includes a positive terminal plate with a liquid storage box, a positive current collector, a positive electrode, a gasket frame, a negative current collector, and a negative terminal plate with a liquid filling box. The effective area of the battery electrode is 4cm 2 , charge and discharge current density: 10mA / cm 2 , the charging time is 10min, the battery performance is as follows figure 2 . The battery Coulombic efficiency is 95%, the voltage efficiency is 89%, and the energy efficiency is 85%.

Embodiment 2

[0032] Battery assembly:

[0033] The positive electrode uses carbon felt with a size of 4x4x0.5cm, and the negative electrode uses a graphite plate with a size of 6.5x 6.5x0.2cm. The electrolyte is 2MZnBr 2 +3MKCl+0.4M MEP.

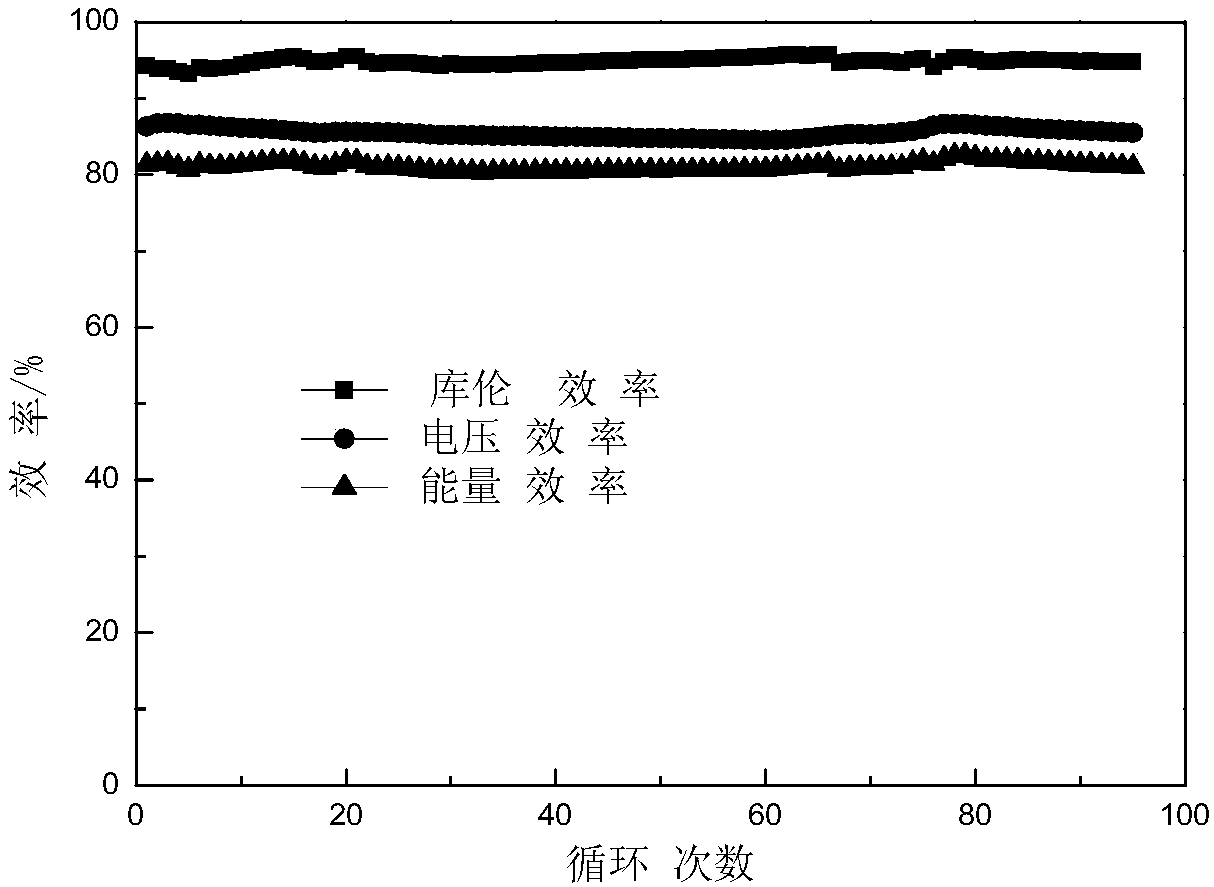

[0034] The single cell sequentially includes a positive terminal plate with a liquid storage box, a positive current collector, a positive electrode, a gasket frame, a negative current collector, and a negative terminal plate with a liquid filling box. The effective area of the battery electrode is 4cm 2 , charge and discharge current density: 15mA / cm 2 , the charging time is 10min, the battery performance is as follows image 3 . The battery Coulombic efficiency is 95%, the voltage efficiency is 85%, and the energy efficiency is 81%.

Embodiment 3

[0036] Battery assembly:

[0037] The positive electrode uses carbon felt with a size of 4x4x0.5cm, and the negative electrode uses a graphite plate with a size of 6.5x 6.5x0.2cm. The electrolyte is 2MZnBr 2 +3MKCl+0.4M MEP.

[0038] A single cell includes a positive terminal plate with a liquid storage box, a positive current collector, a positive electrode, a gasket frame, a negative current collector, and a negative terminal plate with a liquid filling box in sequence. The battery is assembled from left to right. Electrode effective area 4cm 2 , charge and discharge current density: 15mA / cm 2 , the charging time is 10min, the battery performance is as follows Figure 4 . The battery Coulombic efficiency is 90%, the voltage efficiency is 85%, and the energy efficiency is 77%. The coulombic efficiency of batteries assembled from left to right is 5% lower than that of batteries assembled by top-down, indicating that the self-discharge of batteries assembled by top-down i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com