A Design Method for Rotor Core of Permanent Magnet Synchronous Motor

A permanent magnet synchronous motor and rotor core technology, which is applied in the manufacture of motor generators, stator/rotor bodies, electromechanical devices, etc. problems such as a large value range, to achieve the effect of being beneficial to intelligent manufacturing, easy application and promotion, and improving quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

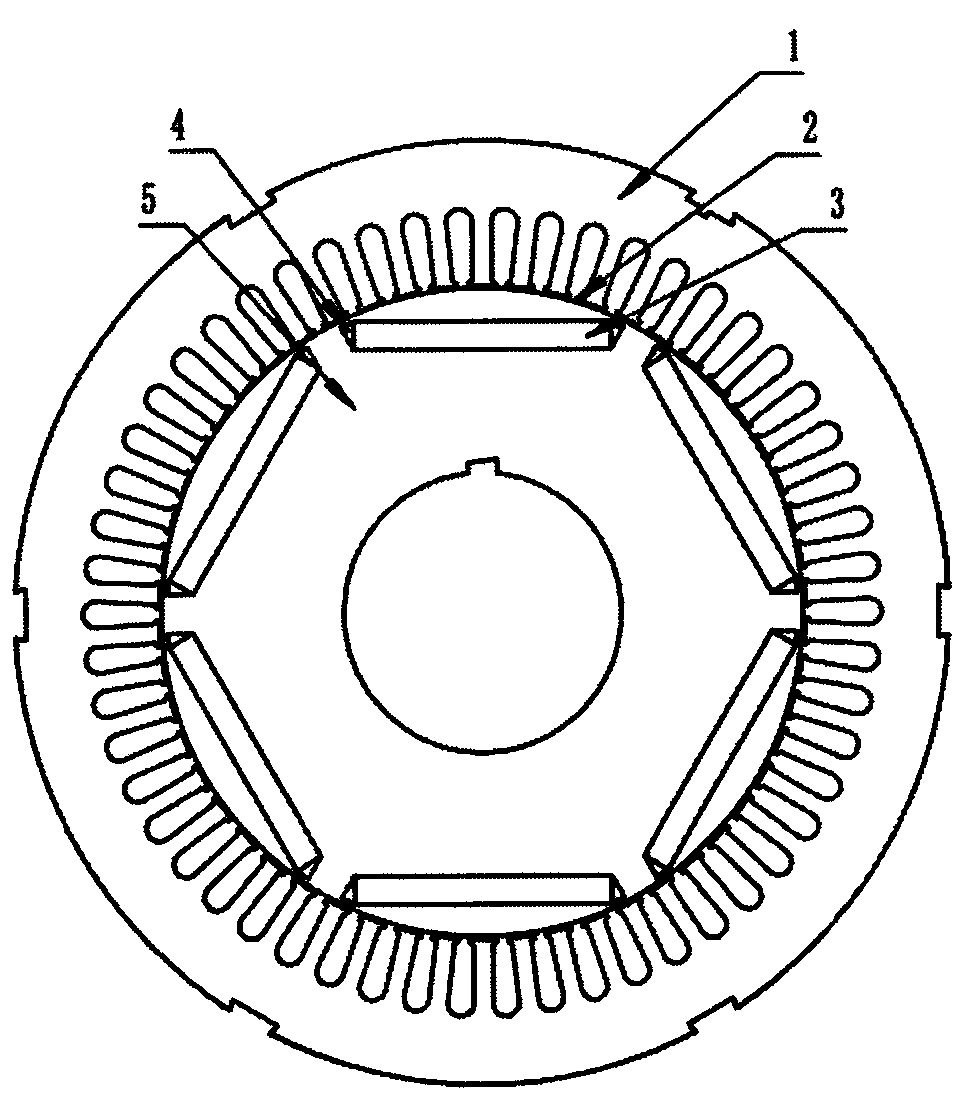

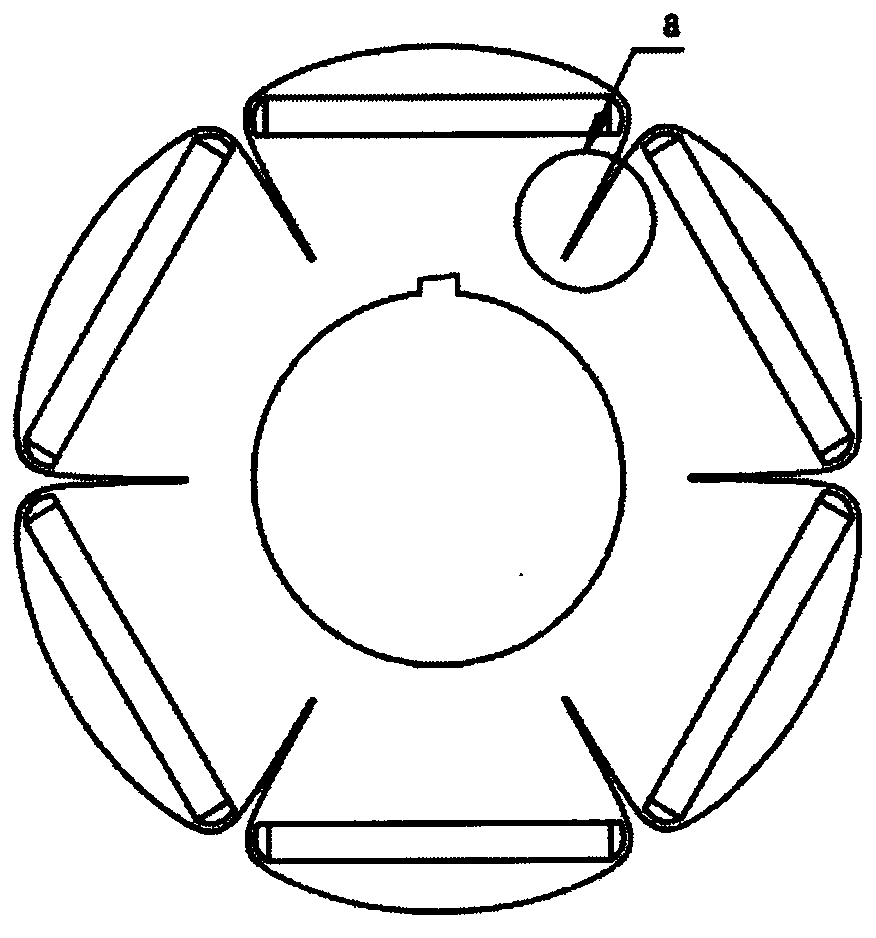

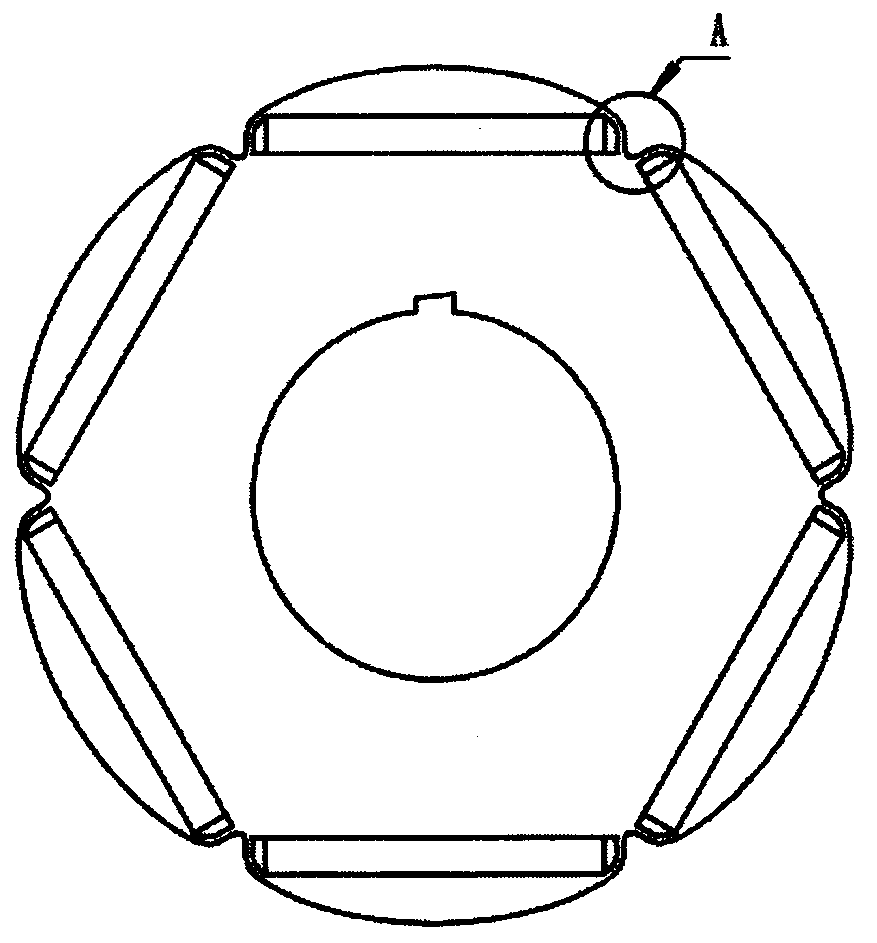

[0030] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

[0031] The present invention improves a permanent magnet synchronous motor rotor core design method, comprising the following steps:

[0032] The magnetic permeability of the air is much smaller than that of the silicon steel sheet. During the operation of the motor, the magnetic potential in the magnetic circuit is mainly concentrated in the air gap with a small magnetic permeability. However, in order to improve the utilization rate of the silicon steel sheet material and improve the The power density of the motor, the magnetic density in the iron core is generally near the knee point, and is in a slightly saturated state, especially in the water-cooled motor, because the heat dissipation effect is better, so in order to reduce the volume or reduce the cost, the volume of the motor is more Small, in order to maintain the output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com