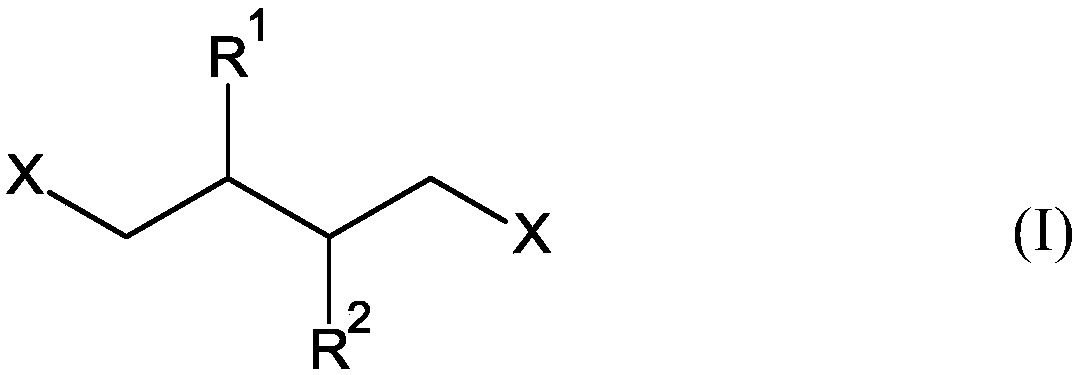

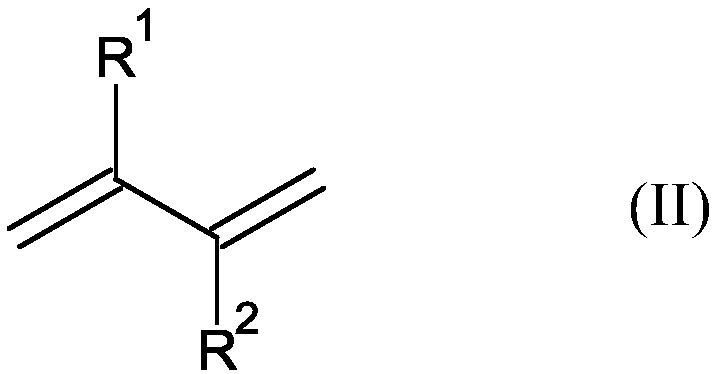

Hydroformylation process for producing 1,6-disubstituted hexane derivatives

A technology of hydroformyl and alkyl, applied in the field of producing polyamide 6.6

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

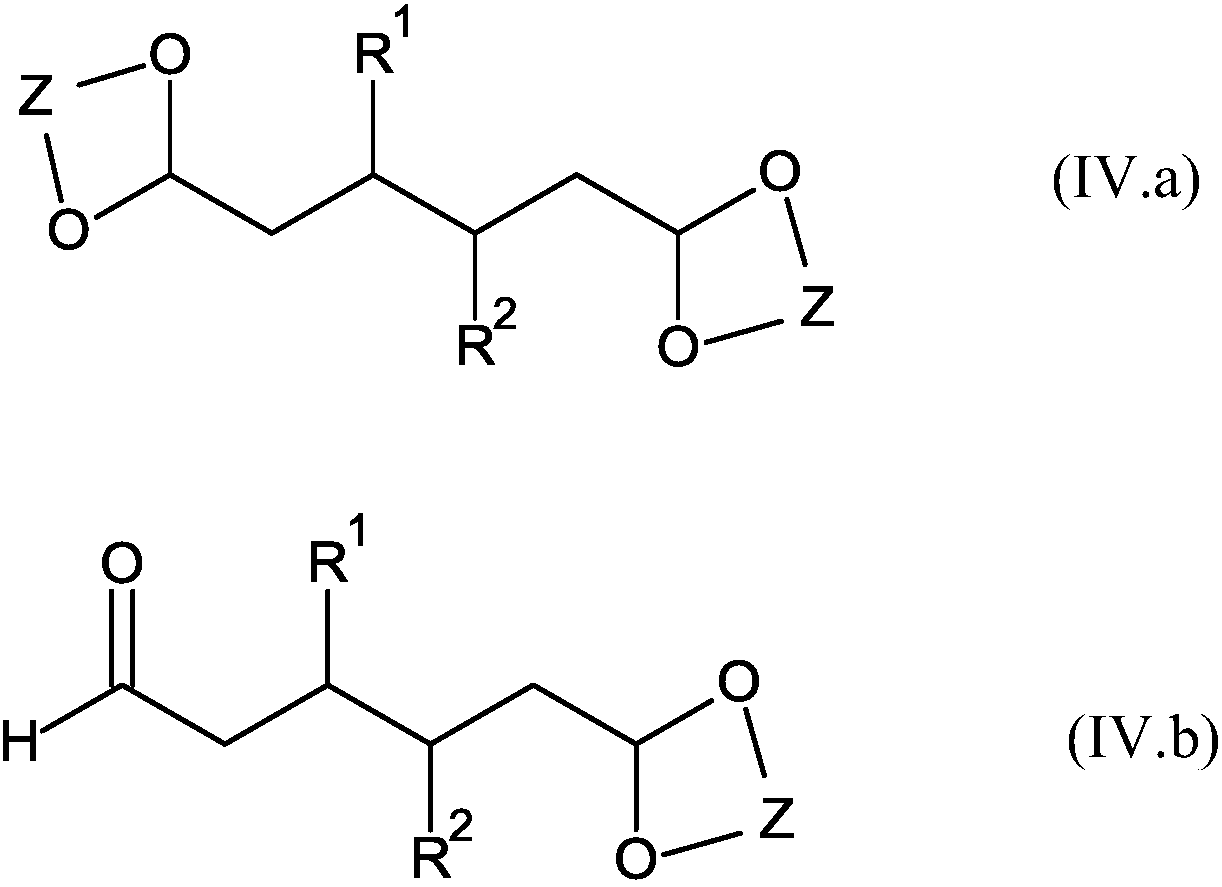

Embodiment 1

[0255] This example was performed using tMe-Ruca phosphite (compound (V.a)) according to the general procedure described above. The autoclave was heated to 80 °C and the reaction mixture was stirred at this temperature for 2 hours. The temperature was raised to 120°C and the reaction mixture was stirred at this temperature for 18 hours. Afterwards, gas chromatographic analysis showed 63% diacetals of 1,6-adipaldehyde, 16% diacetals of 1,2-, 1,3- and 1,4-hexanedial, 14% valeraldehyde acetal, 6% acetal of 3-pentenal and a small amount of other products. The ratio of the diacetals of 1,6-hexanedial to the diacetals of 1,2-, 1,3- and 1,4-hexanedial was 3.9.

Embodiment 2

[0257] This example was carried out according to example 1, except that Biphephos (compound (V.b)) was used instead of tMe-Ruca phosphite (compound (V.a)). Afterwards, gas chromatographic analysis showed 65% of the diacetals of 1,6-hexanedial, 9% of the diacetals of 1,2-, 1,3- and 1,4-hexanedial, 31% of the Acetals of aldehydes and a small amount of other products. The ratio of the diacetals of 1,6-hexanedial to the diacetals of 1,2-, 1,3- and 1,4-hexanedial was 7.2.

Embodiment 3

[0259] This example was performed using tMe-Ruca phosphite (compound (V.a)) according to the general procedure described above. The autoclave was heated to 80 °C and the reaction mixture was stirred at this temperature for 2 hours. The autoclave was cooled to 0 °C by means of an ice bath, and the pressure in the autoclave was reduced to 10 bar. The autoclave was heated to 120° C., and the reaction mixture was stirred at this temperature for 18 hours. Afterwards, gas chromatographic analysis showed 73% of the diacetals of 1,6-hexanedial, 12% of the diacetals of 1,2-, 1,3- and 1,4-hexanedial, 19% of the Acetals of aldehydes and a small amount of other products. The ratio of the diacetals of 1,6-hexanedial to the diacetals of 1,2-, 1,3- and 1,4-hexanedial was 6.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com