Actinic radiation-initiated epoxy adhesive and articles made therefrom

An adhesive and initiator technology, applied in the direction of epoxy resin glue, adhesive type, non-polymer adhesive additives, etc., can solve the problems of long time, short open time, poor storage period and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

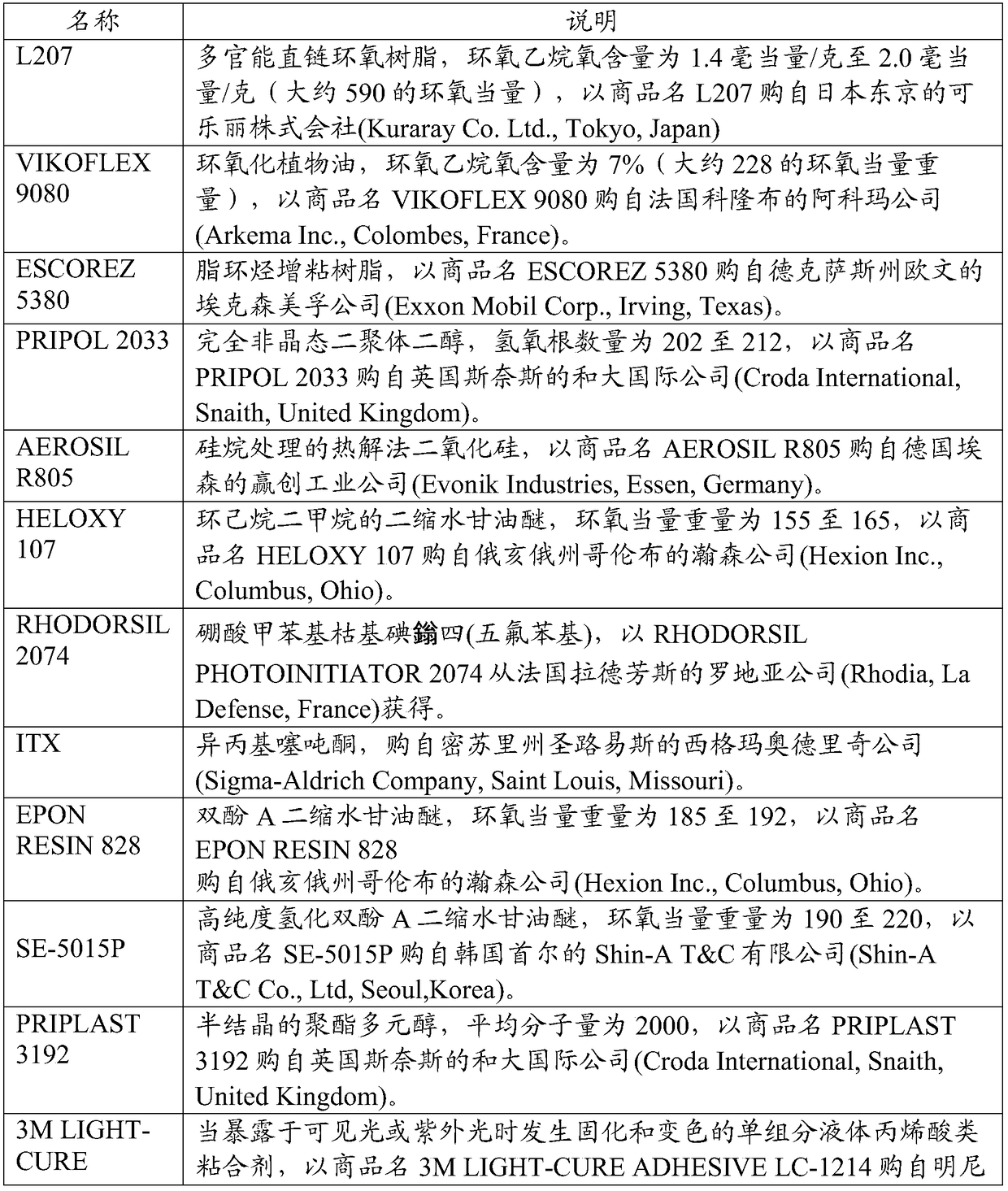

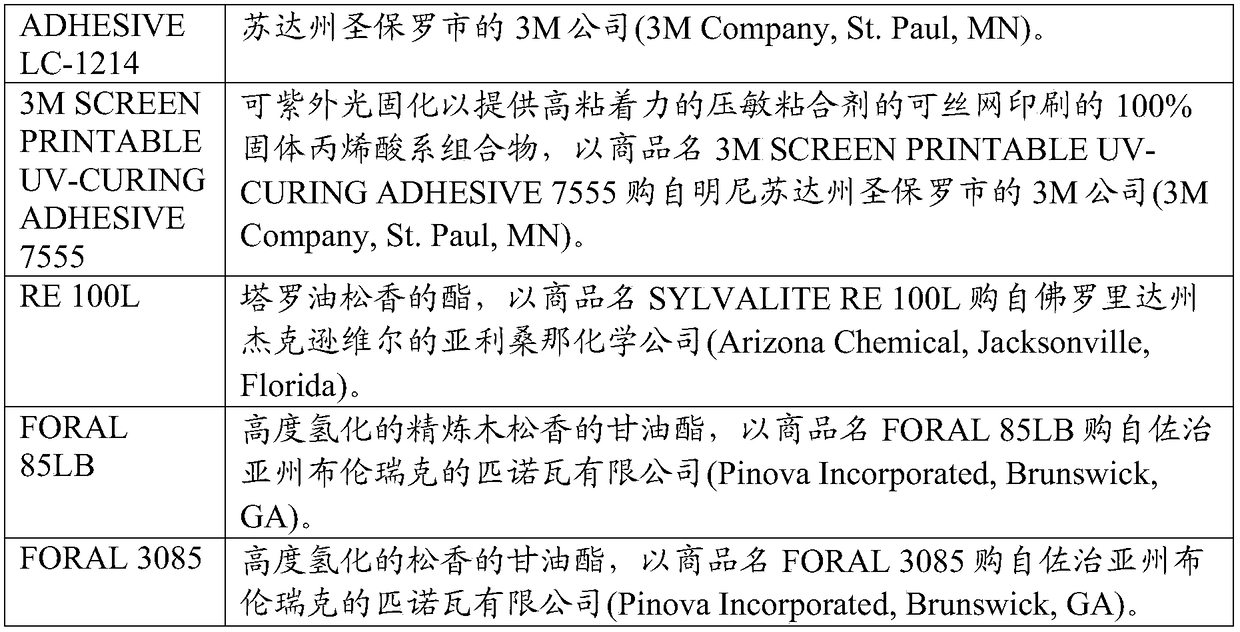

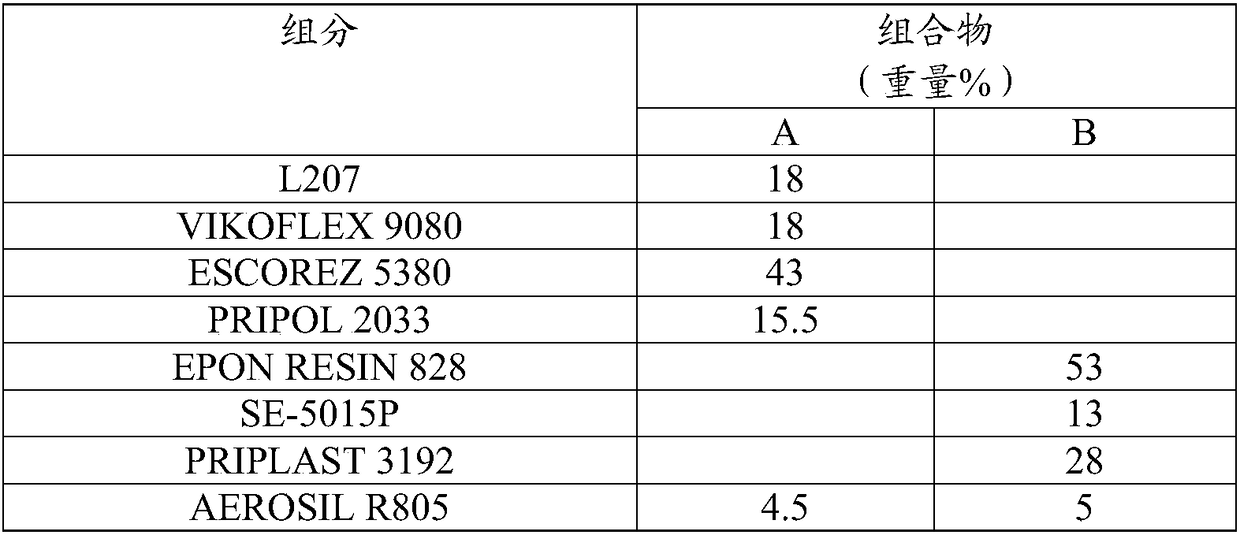

Method used

Image

Examples

Embodiment 1-6 and comparative example A-F

[0024] For each of the following examples and comparative examples, an approximately 2 mm thick bead of adhesive was dispensed in a 1 inch wide bead using an EFD 1500XL DISPENSER from Nordson EFD, Westlake, Ohio. Measure the entire width of a clear polycarbonate (PC) plastic coupon 4 inches long. Immediately after dispensing, the coupons were placed on the conveyor of the FUSION UV CURING SYSTEM available from Fusion UV Systems Inc., Gaithersburg, Maryland, using a D-type bulb The low intensity mercury vapor lamps expose them to various levels of UV-A energy. Total UV-A (320 nm to 390 nm) energy was measured using a UV POWER PUCK II radiometer from EIT Inc., Sterling, Virginia. The total energy exposure is varied by adjusting the conveyor speed. Immediately after 1 second of UV exposure, a 1-inch by 4-inch PC coupon was placed on top of the bead-coated surface of the first coupon, and was obtained using Eunsung Industrial Co., Ltd., Ansan, Korea. Industrial Co., Ltd., Ansan...

Embodiment 7-14 and comparative example G-N

[0029]Examples 7-14 and Comparative Examples G-N were prepared as described in Examples 1-6 and Comparative Examples A-F, with the following modifications. UV-A exposure was fixed at 2.5 J / cm2 and the time elapsed before coupon bonding was varied. The results are reported in Table 4.

[0030] Table 4

[0031]

Embodiment 15-22 and comparative example O-V

[0033] Examples 15-22 and Comparative Examples O-V were prepared as described in Examples 1-6 and Comparative Examples A-F, with the following modifications. UV-A exposure was fixed at 1.0 J / cm2 and the time elapsed before coupon bonding was varied. The results are reported in Table 5.

[0034] table 5

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com