Preparation method of long-shelf life whole concentrated milk

A technology of concentrated milk and milk, applied in dairy products, other dairy products, milk preparations, etc., can solve problems such as inability to transport long distances, loss of nutrients, easy microbial contamination, etc., to ensure nutrition and taste, and solve sensory differences , the effect of extending the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing long-term full-fat concentrated milk, comprising the following steps:

[0031] Raw milk treatment: After the raw milk has passed the inspection and the indicators meet the standardization requirements, it will be degassed.

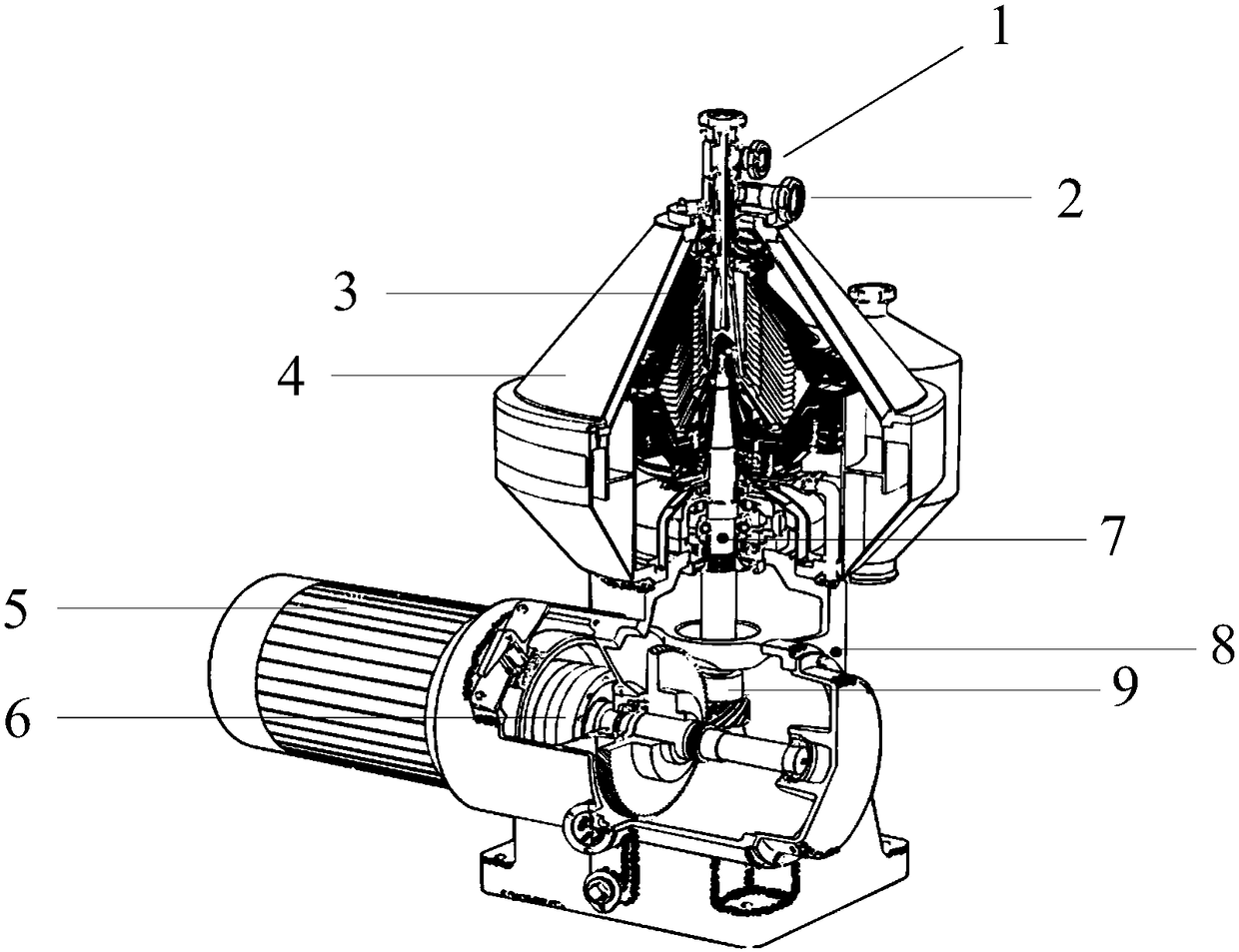

[0032] Efficient milk cleaning and sterilization: the airtight design developed based on advanced fluid dynamics technology uses the centrifugal action of the milk cleaning machine to quickly separate the bacteria and spores in the milk, the flow rate reaches 30000L / h, and the temperature is <50 ℃, the anaerobic spore removal rate reaches 98%, and the aerobic spore removal rate reaches 95%. The product enters the bowl through frequency conversion at the top, and the feed seal effectively prevents product leakage and prevents contact between the product and the air. During the separation, the air is isolated, and the damage of the product particles is avoided through gentle acceleration, while the hydraulically operated automa...

Embodiment 2

[0037] A method for preparing long-term full-fat concentrated milk, comprising the following steps:

[0038] Raw milk treatment: After the raw milk has passed the inspection and the indicators meet the standardization requirements, it will be degassed.

[0039]Efficient milk cleaning and sterilization: the airtight design developed based on advanced fluid dynamics technology uses the centrifugal action of the milk cleaning machine to quickly separate the bacteria and spores in the milk, the flow rate reaches 30000L / h, and the temperature is <50 ℃, the anaerobic spore removal rate reaches 98%, and the aerobic spore removal rate reaches 95%. The product enters the bowl through frequency conversion at the top, and the feed seal effectively prevents product leakage and prevents contact between the product and the air. During the separation, the air is isolated, and the damage of the product particles is avoided through gentle acceleration, while the hydraulically operated automat...

Embodiment 3

[0044] A method for preparing long-term full-fat concentrated milk, comprising the following steps:

[0045] Raw milk treatment: After the raw milk has passed the inspection and the indicators meet the standardization requirements, it will be degassed.

[0046] Efficient milk cleaning and sterilization: the airtight design developed based on advanced fluid dynamics technology uses the centrifugal action of the milk cleaning machine to quickly separate the bacteria and spores in the milk, the flow rate reaches 30000L / h, and the temperature is <50 ℃, the anaerobic spore removal rate reaches 98%, and the aerobic spore removal rate reaches 95%. The product enters the bowl through frequency conversion at the top, and the feed seal effectively prevents product leakage and prevents contact between the product and the air. During the separation, the air is isolated, and the damage of the product particles is avoided through gentle acceleration, while the hydraulically operated automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com