Nano composite gene carrier and preparation method thereof

A technology of carboxymethyl cellulose and polyethylene imine, which can be applied to other methods of inserting foreign genetic materials, recombinant DNA technology, etc., can solve problems such as application restrictions and increase cytotoxicity, achieve high biocompatibility, improve Transfection efficiency, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

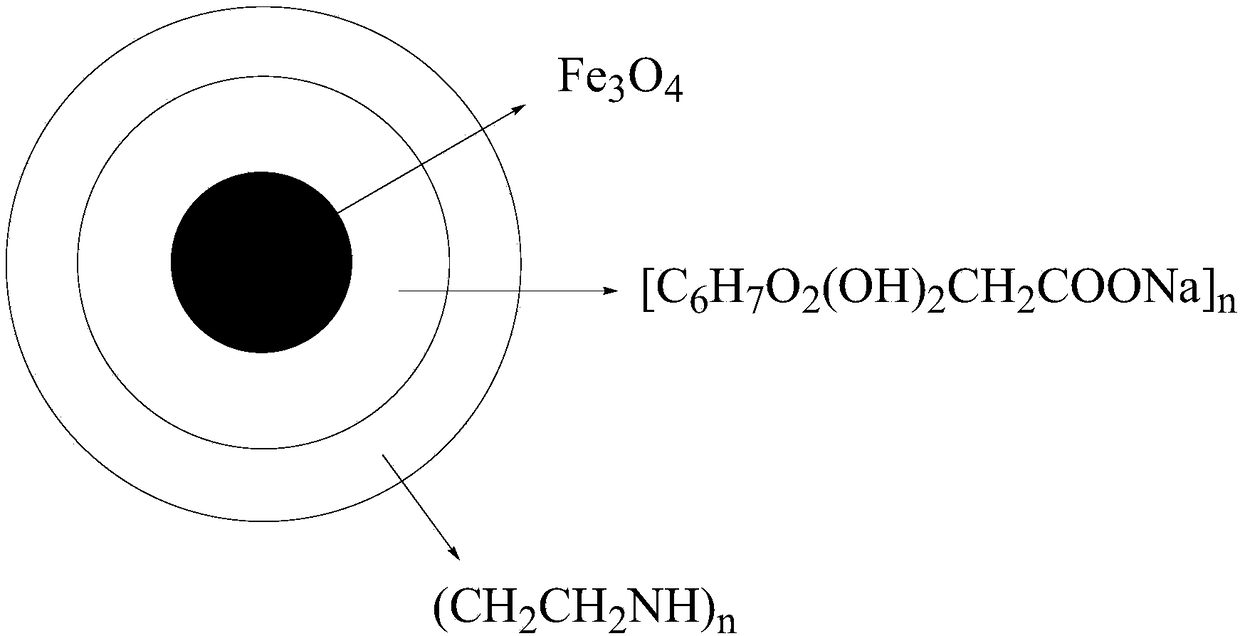

[0026] Soluble ferrous chloride, ferric chloride and carboxymethylcellulose (calculated as cellobiose residues) are added to the reaction vessel according to 1mol:1.5mol:1mol, and then 100mol1-ethyl-3-methylimidazole is added Glycoacetic acid salt was fully dissolved and dispersed, and ammonia water and epichlorohydrin were added at 60 ° C for 1 hour to obtain magnetic Fe with carboxymethyl cellulose shell. 3 o 4 . 10 g of the obtained magnetic Fe with a carboxymethyl cellulose shell 3 o 4 , 20g of polyethyleneimine (molecular weight: 25kDa) and 40g of epichlorohydrin were added to the reaction vessel, then distilled water was added, and the reaction was stirred at 30°C for 24h to obtain iron ferric oxide-carboxymethyl cellulose with a core-shell structure - Polyethyleneimine nanocomposite gene carrier, such as figure 1 shown.

Embodiment 2

[0028] Soluble ferrous chloride, ferric nitrate and carboxymethyl cellulose (calculated as cellobiose residue) are added to the reaction vessel according to 1mol:2.5mol:1mol, and then 200mol1-ethyl-3-methylimidazolium methyl Acetate is fully dissolved and dispersed, and ammonia water and epichlorohydrin are added to react for 3 hours at 90°C to obtain magnetic Fe with a carboxymethyl cellulose shell. 3 o 4 . 10 g of the obtained magnetic Fe with a carboxymethyl cellulose shell 3 o 4 , 10g polyethyleneimine (molecular weight is 750kDa) and 15g epichlorohydrin are added to the reaction vessel, then distilled water is added, stirred and reacted at 30°C for 4h, and ferric oxide-carboxymethyl cellulose with core-shell structure is obtained - Polyethyleneimine nanocomplex gene carrier.

Embodiment 3

[0030] Soluble ferrous nitrate, ferric sulfate and carboxymethyl cellulose (calculated as cellobiose residues) are added to the reaction vessel according to 1mol:2.5mol:2mol, and then 55mol1-ethyl-3-methylimidazoliummethyl ethyl The acid salt is fully dissolved and dispersed, and ammonia water and epichlorohydrin are added to react for 1.5 hours at 75°C to obtain magnetic Fe with a carboxymethyl cellulose shell. 3 o 4 . 10 g of the obtained magnetic Fe containing carboxymethyl cellulose shell 3 o 4 , 20g polyethyleneimine (molecular weight is 100kDa) and 20g epichlorohydrin are added in the reaction container, then add distilled water, stir and react at 30 ℃ for 0.5h, obtain ferric oxide-carboxymethyl fiber with core-shell structure DNA-polyethyleneimine nanocomposite gene carrier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com