Crack repairing structure capable of being easily, conveniently and quickly constructed and construction method thereof

A fast technology for crack repair, applied in building structure, building maintenance, epoxy resin glue, etc., can solve the problems of secondary cracking, short curing time, poor filling and repairing effect, etc., to improve fluidity and shorten construction the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1" is substantially the same as Embodiment 1', the difference being that the cracks 11 of the wall body 1 in Embodiment 1" are distributed laterally.

Embodiment 1a

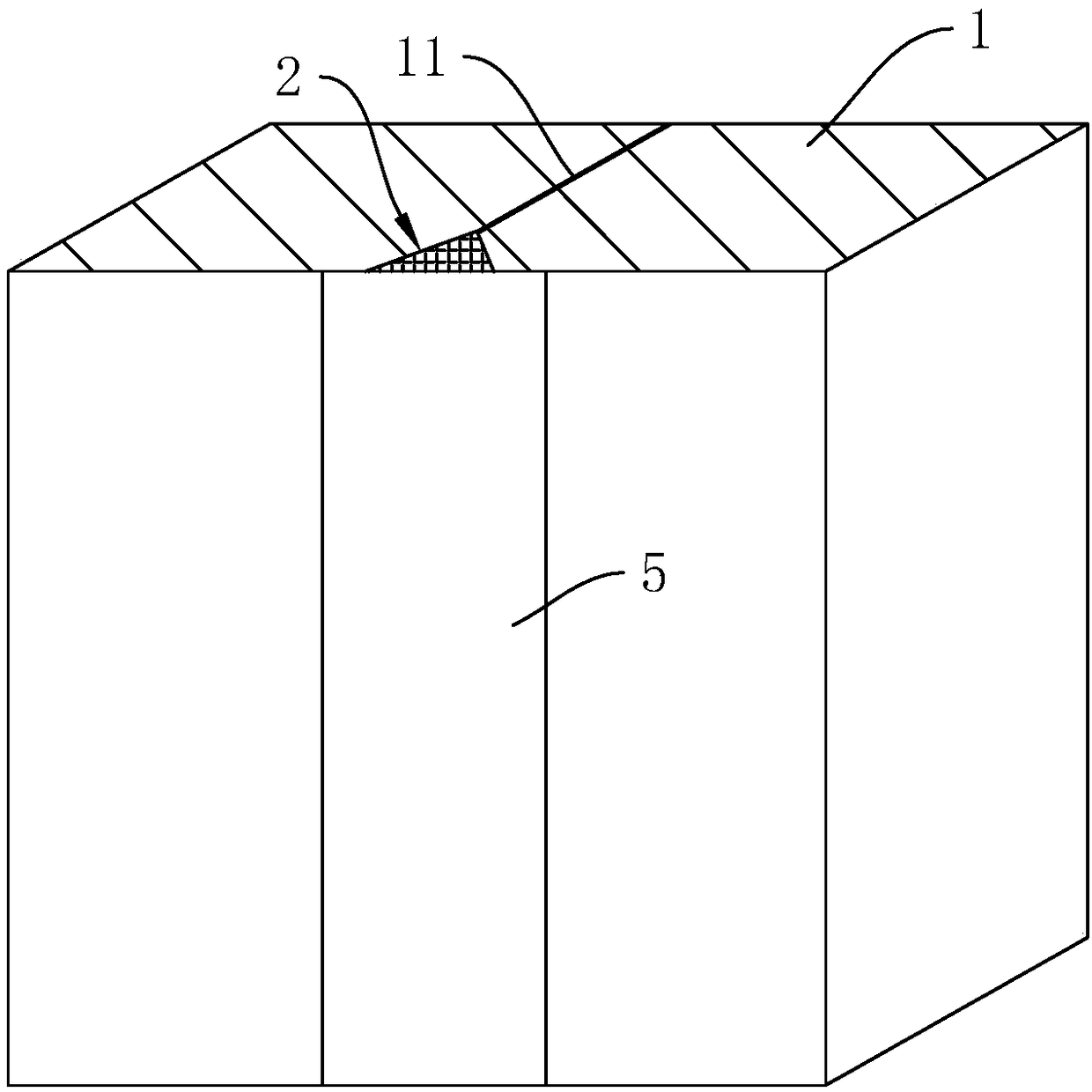

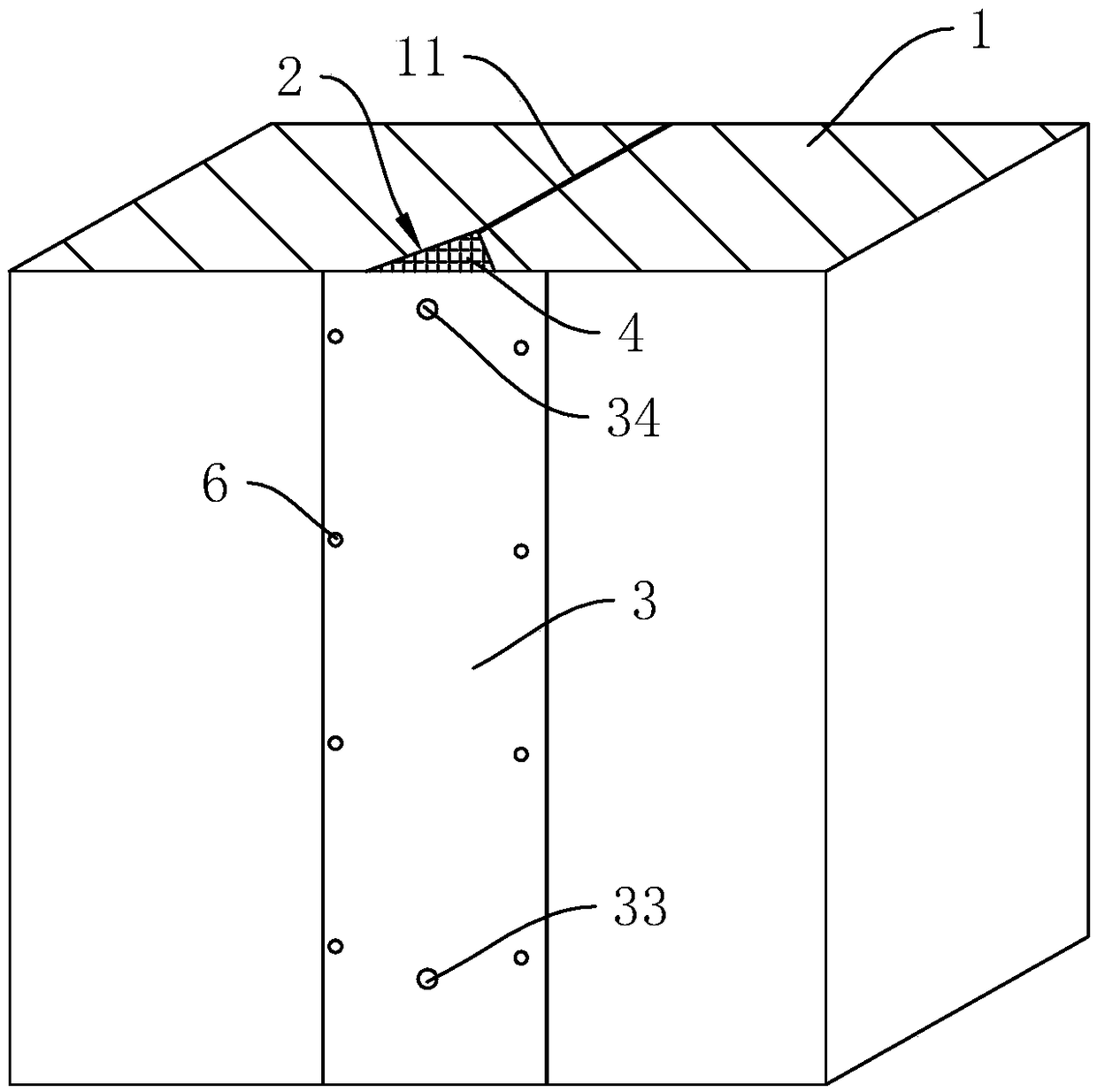

[0046] see Figure 1 to Figure 4 , a construction method of a crack repair structure that is simple and fast in construction, comprising the following steps:

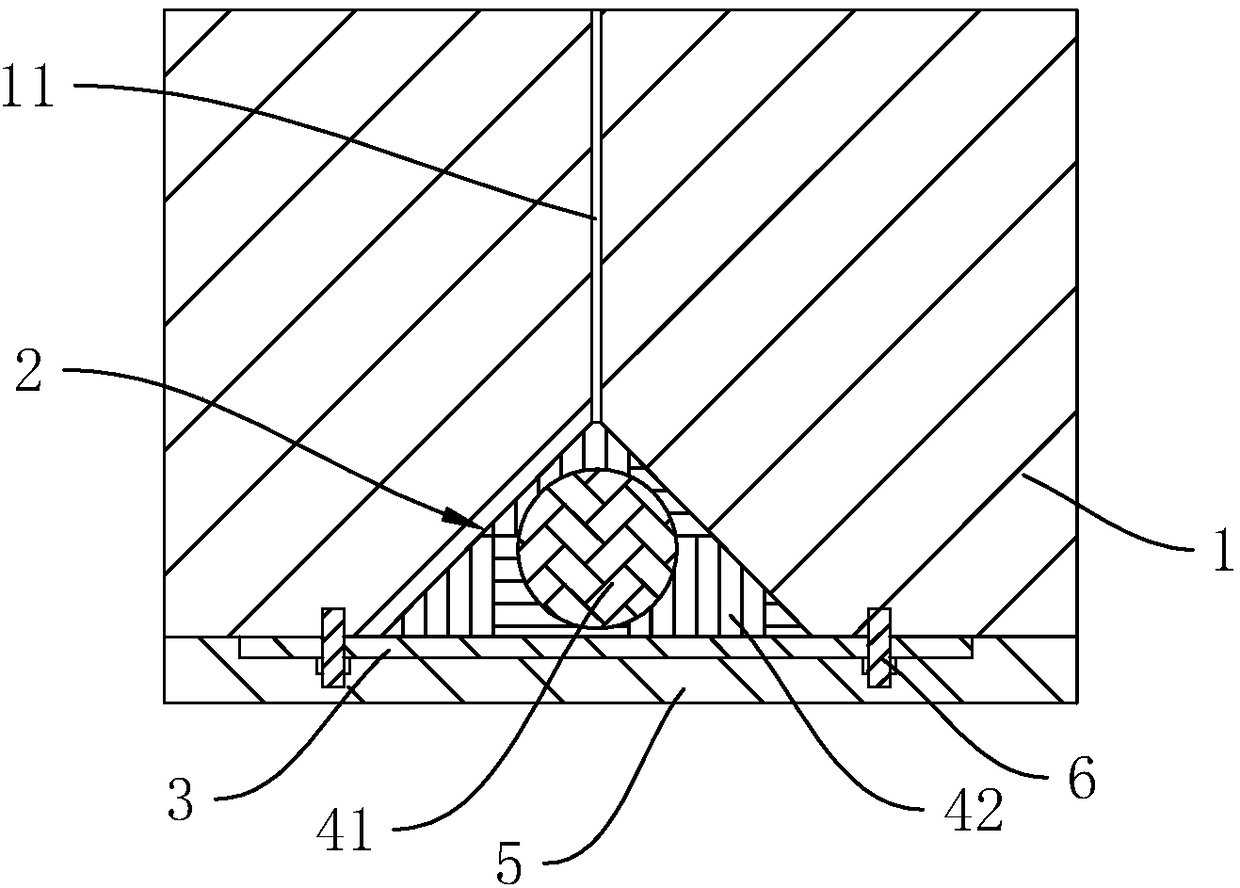

[0047] Step1, open a V-shaped long groove 2 along the direction of the crack 11 on the part of the wall 1 where there are cracks 11. The depth of the V-shaped long groove 2 is 3cm, and fill the intertwined cotton thread and carbon fiber thread in the V-shaped long groove 2 as the filling line 41;

[0048] Step2.1, the first transparent polypropylene woven cloth 311, the first absorbent cotton cloth 312, the steel wire frame 313, the second absorbent cotton cloth 314 and the second transparent polypropylene woven cloth 315 are sequentially laminated and compacted to form the base layer 31;

[0049] Step2.2, after coating the upper and lower surfaces of the base layer 31 with UV-curable acrylic adhesive 32, fix the base layer 31 to the opening of the V-shaped long groove 2 through the anchor bolt 6, and close the opening...

Embodiment 1b

[0056] see Figure 1 to Figure 4 , a construction method of a crack repair structure that is simple and fast in construction, comprising the following steps:

[0057] Step1, open a V-shaped long groove 2 along the direction of the crack 11 on the part of the wall 1 where there are cracks 11. The depth of the V-shaped long groove 2 is 8cm, and fill the intertwined cotton thread and carbon fiber thread in the V-shaped long groove 2 as the filling line 41;

[0058] Step2.1, the first transparent polypropylene woven cloth 311, the first absorbent cotton cloth 312, the steel wire frame 313, the second absorbent cotton cloth 314 and the second transparent polypropylene woven cloth 315 are sequentially laminated and compacted to form the base layer 31;

[0059] Step2.2, after coating the surface of the base layer 31 with a UV-curable acrylic adhesive 32, fix the base layer 31 to the opening of the V-shaped long groove 2 through the anchor bolt 6, and close the opening of the V-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com