An integral clutch piston for a transmission

A clutch, integral technology, applied in the direction of fluid-driven clutches, clutches, non-mechanical drive clutches, etc., can solve the problems of piston seal failure, clutch failure, piston chamber abrasion, etc., to achieve good strength, strong sealing, and assembly Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

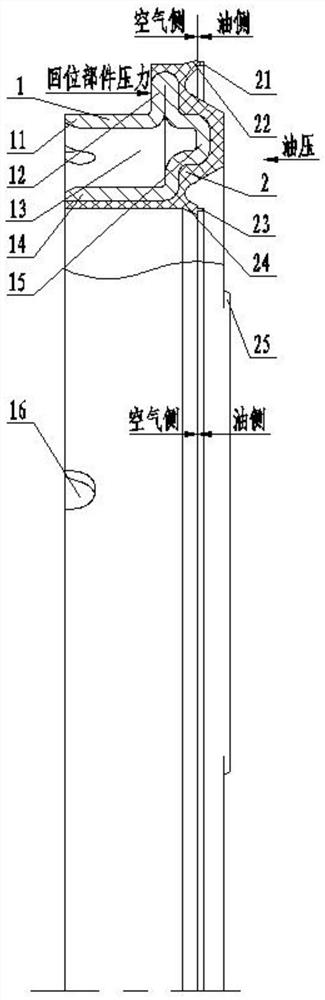

[0019] Such as figure 1 As shown, an integral clutch piston for a transmission, the piston is disc-shaped, including a skeleton 1 and a sealing body 2, the skeleton 1 is provided with an outer mold side end 11, an outer protrusion 12, an oil storage cavity 13, an inner The friction end 14 and the inner protrusion 15, wherein the friction part of the skeleton 1 is composed of two ring-shaped end faces of the inner friction end 14 and the outer mold side end 11, one side of the oil storage cavity 13 is the outer mold side end 11, and the other is the outer mold side end 11. The side is the inner friction end 14, and the inner protrusion 12 is located between the inner friction end 14 and the outer mold side end 11, connected with the outer mold side end 11 and the inner friction end 14 and protruding toward the oil side; the outer pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com