Pressure sensor temperature drift compensation circuit and compensation method

A technology of pressure sensor and temperature drift compensation, which is applied in the direction of measuring fluid pressure, instruments, measuring force, etc. It can solve the problems that the temperature coefficient of sensor sensitivity cannot be accurately compensated, and the calculation results are not necessarily accurate and different, and achieve simple circuit structure and compensation High precision and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

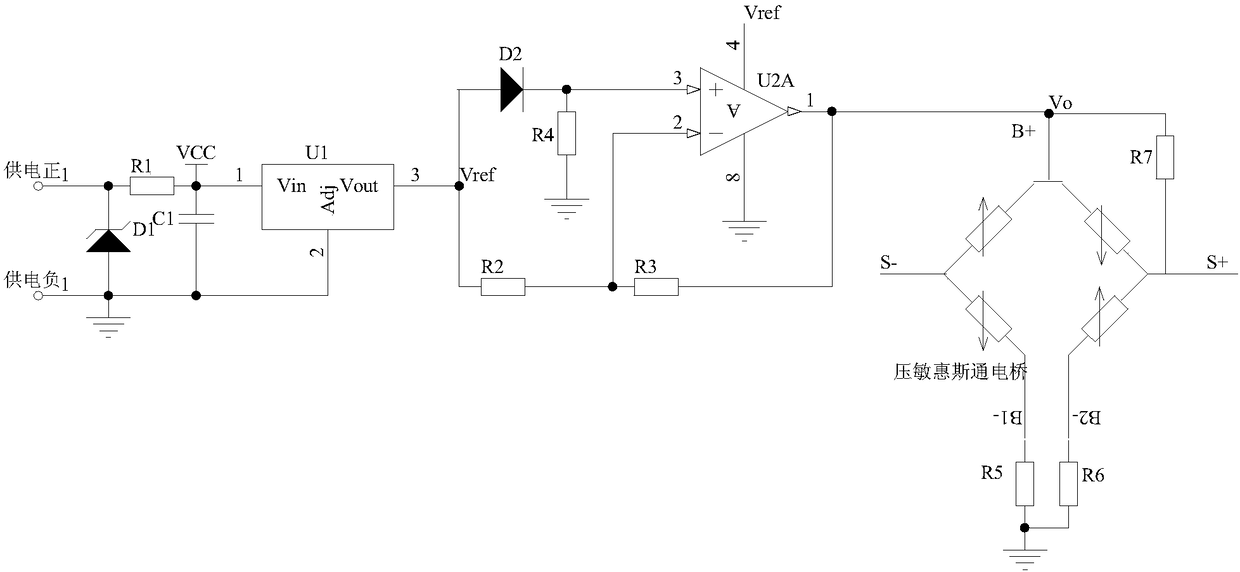

[0023] Such as figure 1 As shown, the pressure sensor temperature drift compensation circuit of this embodiment includes a subtractor, wherein the subtractor includes an operational amplifier U2A, a diode D2, a first resistor R2, a second resistor R3 and a third resistor R4, and the output of the operational amplifier connected to the input terminal of the pressure-sensitive Wheatstone bridge of the pressure sensor, the inverting input terminal of the operational amplifier is connected to the input power supply of the subtractor through the first resistor, and the inverting input terminal and the output terminal of the operational amplifier are connected through the second connected to the resistors, the non-inverting input terminal of the operational amplifier is connected to the ground through the third resistor, and connected to the input po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com