Horizontal flour mixer with automatic humidity control device and safety protection device

A safety protection device and noodle mixing machine technology, which is applied to dough mixers, structural components of mixing/kneading machines, mixing/kneading with vertical installation tools, etc. High strength, low control precision and other problems, to achieve the effect of convenient and quick way of taking noodles, reducing labor intensity and improving control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the drawings.

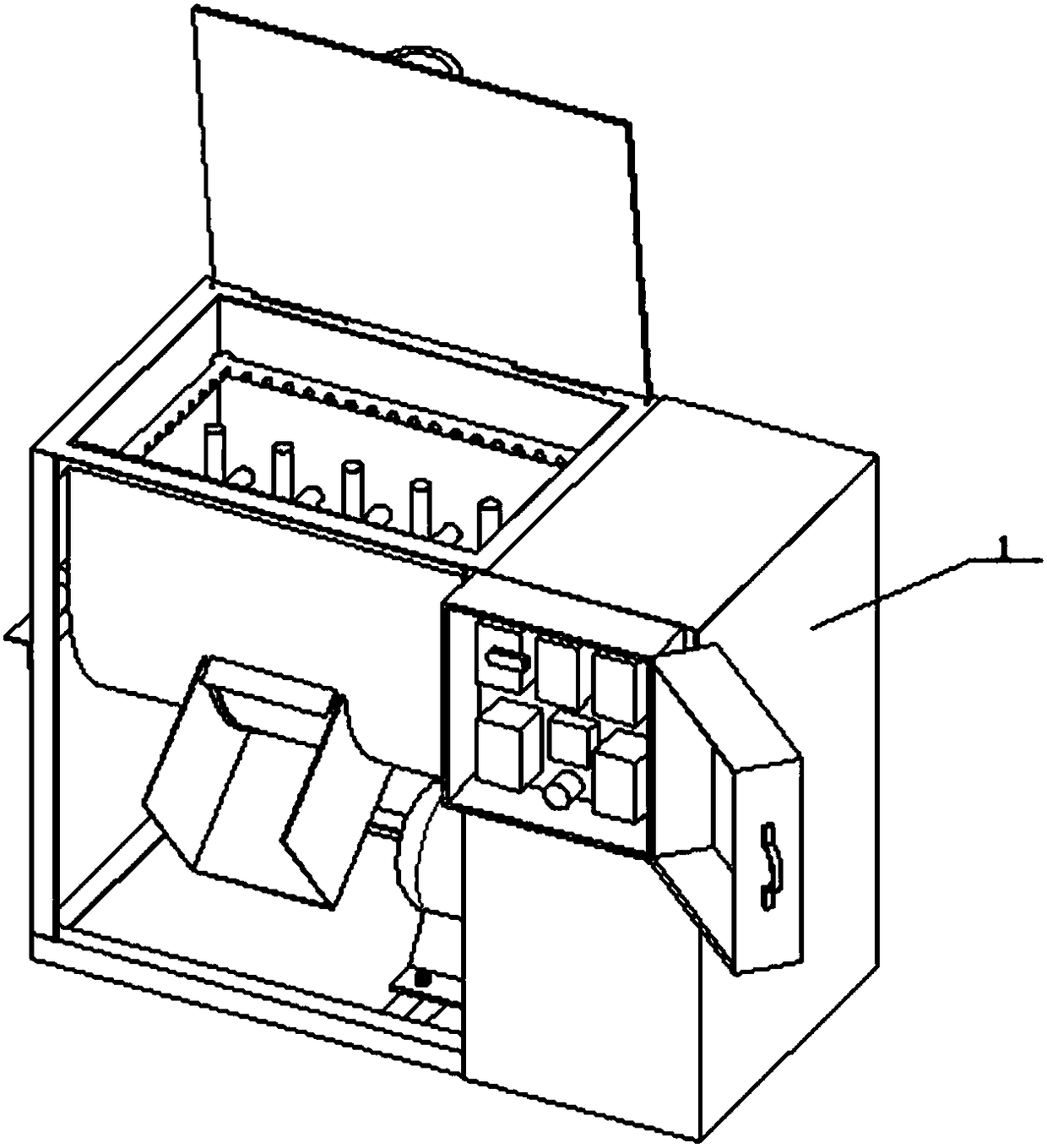

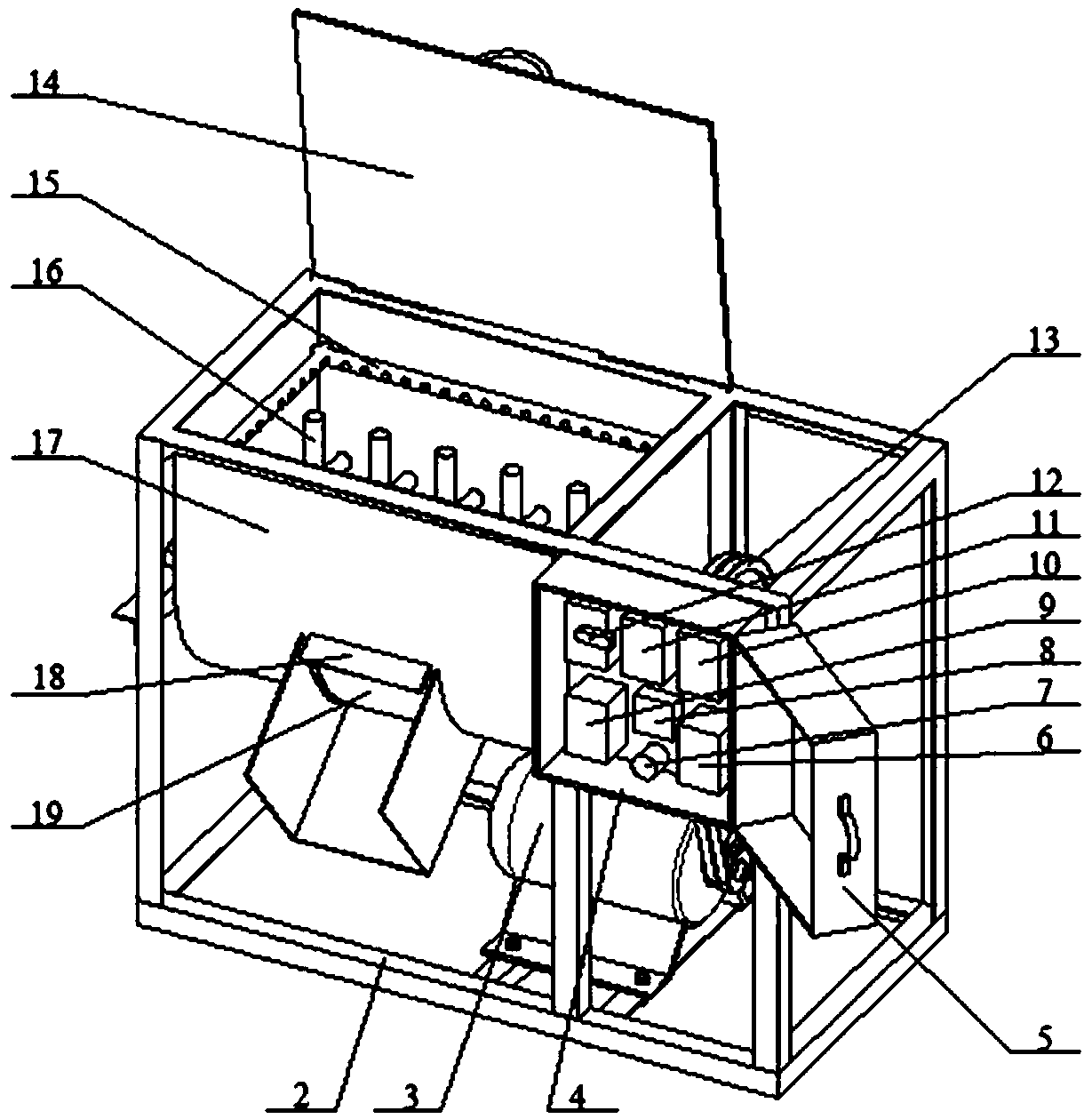

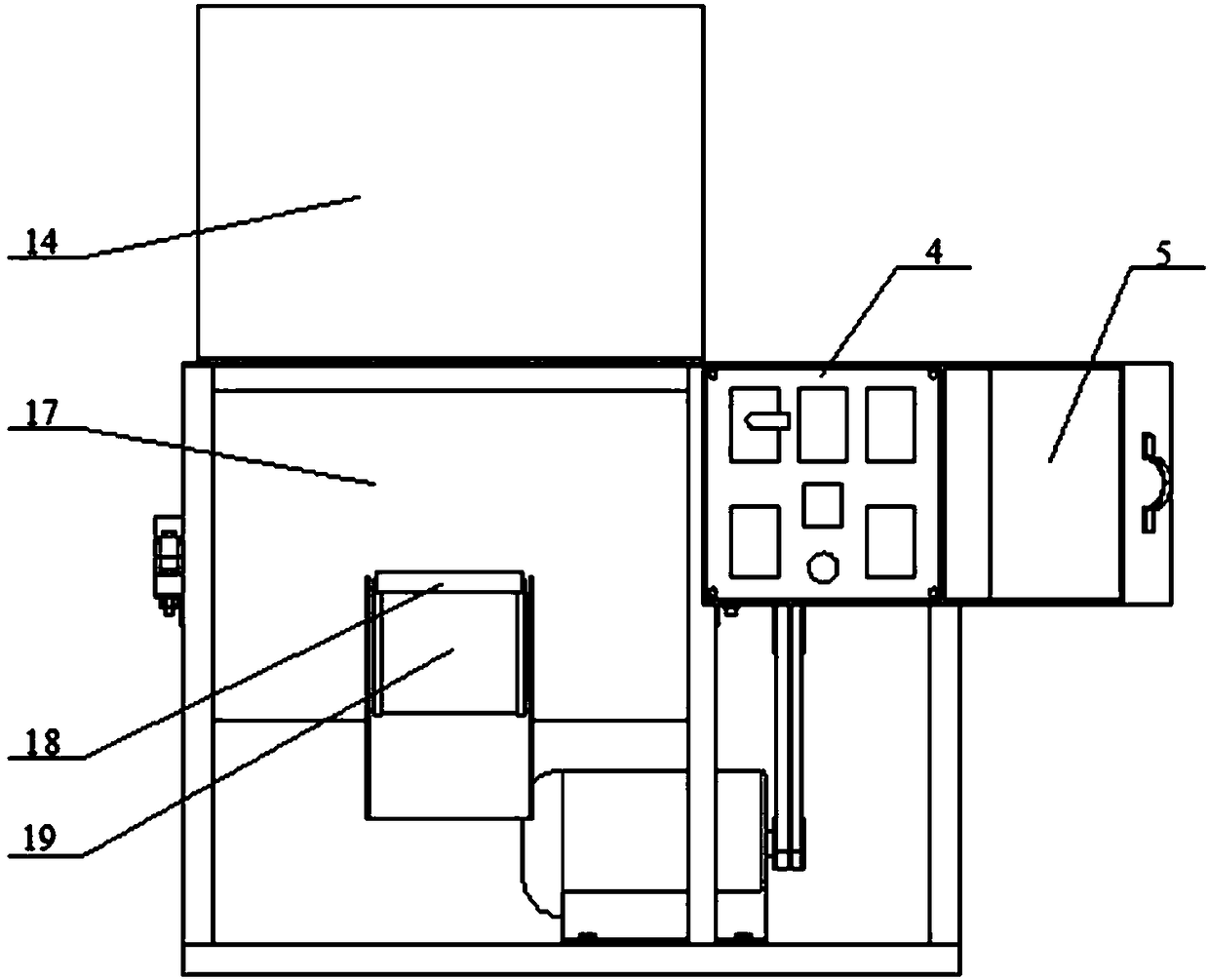

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 The horizontal noodle mixer with automatic humidity control device and safety protection device shown includes a frame 2, a power part, a working part and a control part; the power part, working part and control part are installed on the frame 2 The power part includes a motor 3, the motor 3 is fixed on the frame 2 by bolts; the working part includes a surface box, a stirring device, a water supply device and a discharge device, the surface box includes a box cover 14 and a box The body 17, the box cover 14 and the box body 17 are connected by a hinge, the box body 17 and the stirring shaft 20 are connected by a bearing, the stirring device includes a stirring rod 16 and a stirring shaft 20, the stirring rod 16 is fixed Connected to the stirring shaft 20, the stirring shaft 20 is connected to the fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com