Chenopodium quinoa health-care bread and making method thereof

A production method and quinoa technology, which are applied in the processing of dough, baking, and baked goods with modified ingredients, etc., can solve the problems of limiting the addition amount, reducing the health-care effect of quinoa, and achieving enhanced elasticity, good practical significance, The effect of good preservation of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment relates to a quinoa health-care bread and a preparation method thereof.

[0034] The quinoa health-care bread of the present embodiment is made from the following raw materials in parts by weight: 80-120 parts of high-gluten flour, 10-60 parts of quinoa homogenate after debittering, 1-10 parts of gluten, 1-10 parts of yeast 4 parts, white sugar 5-15 parts, butter 0-8 parts, salt 1-4 parts, eggs 0-12 parts, milk 15-40 parts, water 10-60 parts.

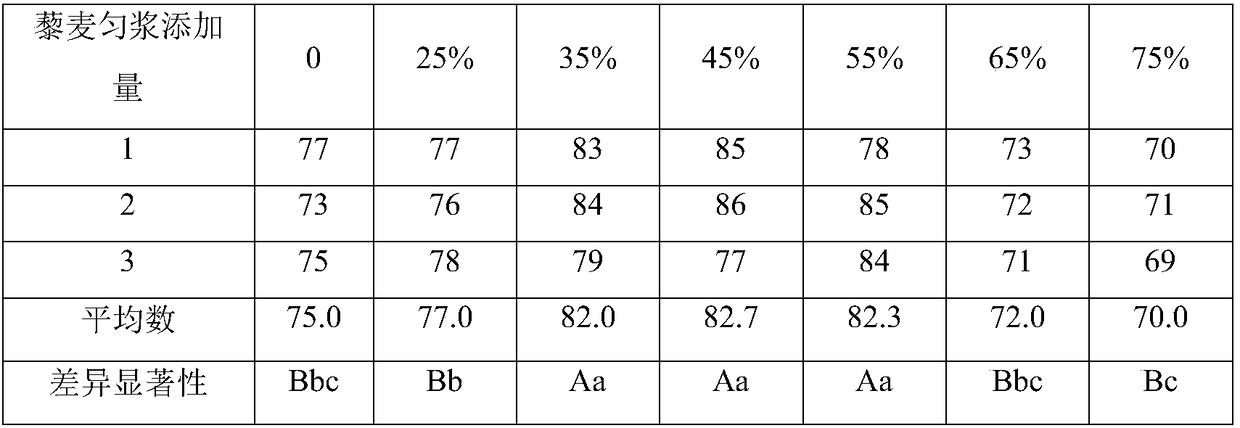

[0035] Wherein, in the composition of the above raw materials, the total parts by weight of water and milk are preferably 40-70 parts, quinoa homogenate is preferably 55% of the weight of high-gluten flour, and gluten is preferably 55% of the weight of high-gluten flour. 3%. And the quinoa homogenate is preferably made of white quinoa, so that the sensory characteristics of the bread made are good, and in addition, the aforementioned yeast is preferably active dry yeast.

[0036] The preparation method of the ab...

example 1

[0038] The quinoa health bread made specifically includes the following raw materials: 100g of high-gluten flour, 55g of debittered quinoa homogenate, 3g of gluten powder, 1.5g of salt, 3g of active dry yeast, 10g of white sugar, 5g of butter, and salt 1.5g, 20g eggs, 20g milk, 30g water.

[0039] The making method of this quinoa health bread then comprises the following steps:

[0040] Step a, raw material pretreatment:

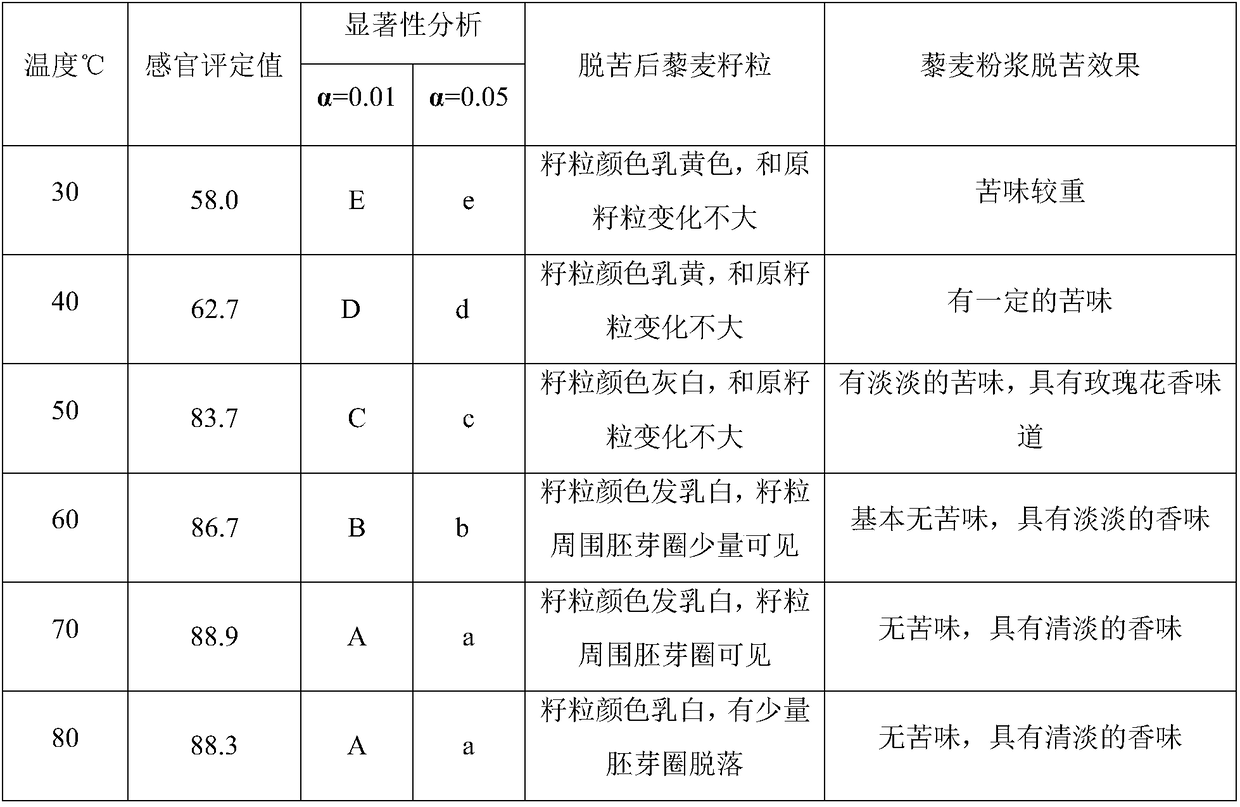

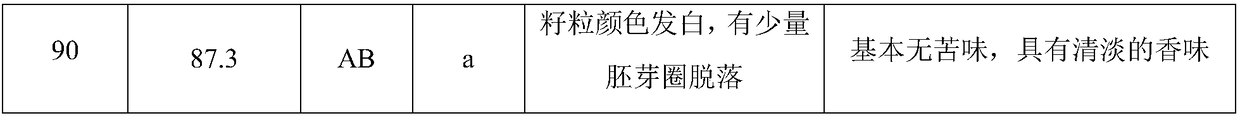

[0041] a1. Debittering of quinoa: mix white quinoa with a volume ratio of 1:8 and water, soak for 1 hour at a soaking temperature of 90°C, rinse twice with the same volume of water, and boil for 3 minutes in boiling water;

[0042] a2, quinoa refining: filter the cooked quinoa with gauze and add it to the refiner, then add an equal volume of water to the refiner for refining, and refine twice to obtain quinoa homogenate ;

[0043] a3. Active dry yeast activation: dissolve the active dry yeast in warm water at 35°C, the amount of water to dissolve the acti...

example 2

[0051] The quinoa health bread made specifically includes the following raw materials: 100g of high-gluten flour, 55g of debittered quinoa homogenate, 2g of gluten powder, 1.5g of salt, 3g of active dry yeast, 10g of white sugar, 5g of butter, and salt 1.5g, 20g eggs, 20g milk, 30g water.

[0052] The making method of this quinoa health bread then comprises the following steps:

[0053] Step a, raw material pretreatment:

[0054] a1. Debittering of quinoa: mix white quinoa with a volume ratio of 1:8 and water, soak for 1 hour at 80°C, rinse twice with the same volume of water, and boil for 3 minutes in boiling water;

[0055] a2, quinoa refining: filter the cooked quinoa with gauze and add it to the refiner, then add an equal volume of water to the refiner for refining, and refine twice to obtain quinoa homogenate ;

[0056] a3. Active dry yeast activation: dissolve the active dry yeast in warm water at 35°C, the amount of water to dissolve the active dry yeast is 3.5 times...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com