Modularized combined type deodorizing device

A combined and modular technology, applied in chemical instruments and methods, gas treatment, membrane technology, etc., can solve the problems of complex management and maintenance, large footprint, high operating costs, etc., to achieve simple management and maintenance, small footprint , the effect of low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

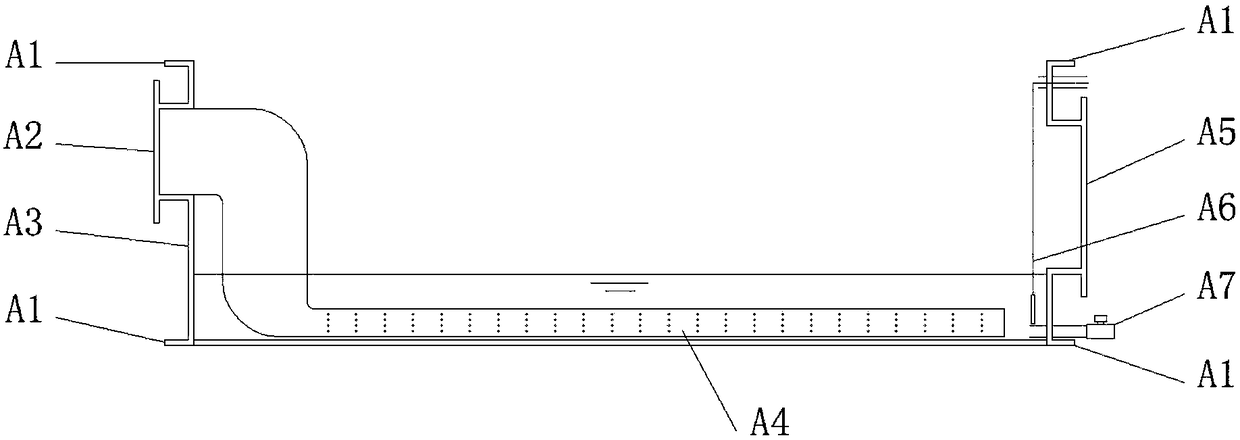

Embodiment 1

[0053] Figure 7 This is a structural diagram of a modular combined deodorization device provided by Embodiment 1 of the present invention. The device is composed of an aeration module, an I-type filler module and a top cover module. The odorous gas collected centrally is collected from the air inlet of the aeration module. Enter the equipment, after being evenly aerated by the aeration pipe, after contacting with alkaline microorganisms, it enters the I-type packing module; the air distribution plate in the I-type packing module evenly distributes the air and contacts with the microbial packing in the weak acid environment. The pH value and temperature of the packing are The humidity is controlled by the sensor to adjust the spray humidification head; some pollutants are degraded and enter the second-layer I-type filler module, and after evenly distributing the air, they contact the second-layer acidic environment microbial filler. The pH, temperature and humidity of the filler ...

Embodiment 2

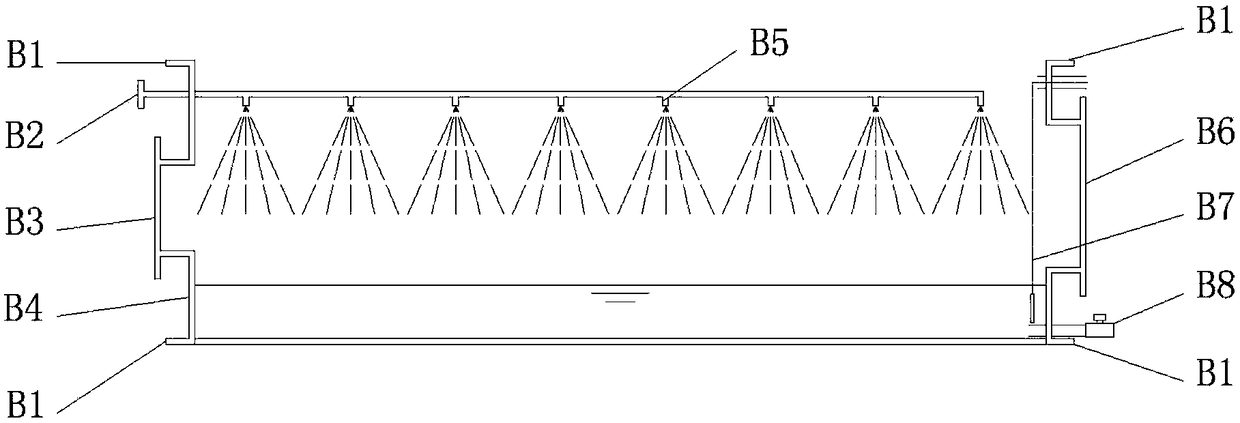

[0055] Figure 8 This is a structural diagram of a modular combined deodorizing device provided in the second embodiment of the present invention. The device is composed of an enhanced washing module, a type I packing module, a dehumidification module, a type II packing module and a top cover module, and the odor is collected in a centralized manner. The gas enters the equipment from the air inlet of the enhanced washing module, and the enhanced washing nozzle sprays alkaline microbial diluent, which reacts with the pollutants in the malodorous gas and absorbs some pollutants; the malodorous gas after the enhanced washing enters the I-type packing module , The air distribution plate evenly distributes the air and contacts with the microbial filler in the weak acid environment. The pH, temperature and humidity of the filler are adjusted by the sensor controlled spray humidification head. Some pollutants are degraded and enter the dehumidification module, after passing through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com