Method for crushing fine powders of whole rice for fuel ethanol production

A fuel ethanol and fine powder technology, applied in grain processing and other directions, can solve the problems affecting the qualified feed particle size and the unqualified fine powder particle size, etc., and achieve the effects of improving production economic benefits, reducing power and energy consumption, and increasing output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

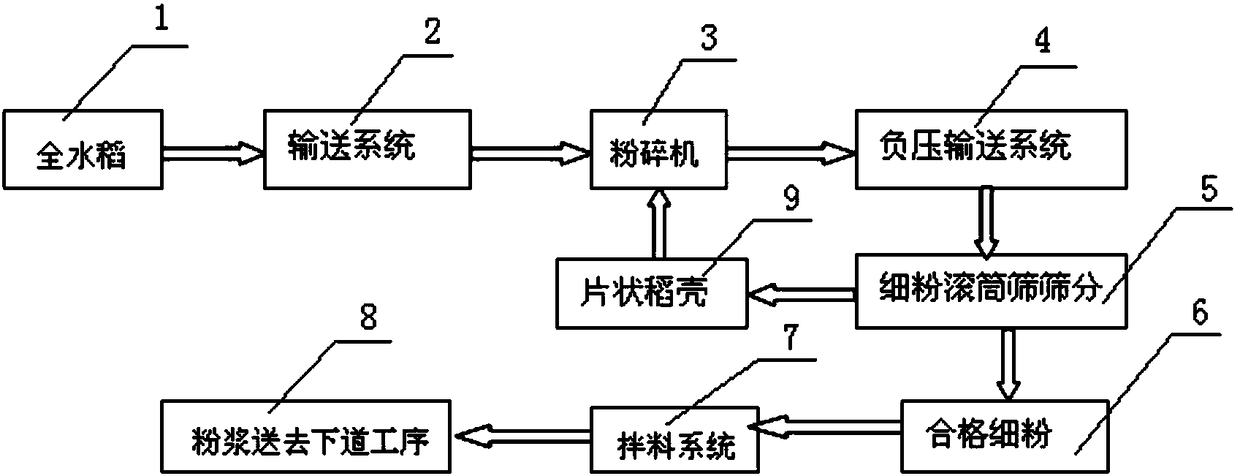

[0020] A method of crushing fine powder of whole rice for fuel ethanol production, such as figure 1 As shown, the process description: the whole rice 1 is sent to the pulverizer 3 through the conveying system 2, and the fine powder after the crushing of the whole rice is conveyed and separated by the negative pressure conveying system 4, and the fine powder enters the fine powder drum sieve for screening 5, and the undersize is Qualified fine powder 6 enters the mixing system 7 to mix the material and adjust the slurry, the slurry is sent to process 8, the fine powder enters the fine powder drum sieve and sieves 5, and the oversize is flake rice husk 9 returns to the pulverizer 3 for re-grinding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com