Fully-automatic coating replenishment device

A fully automatic and coating technology, applied in the direction of spraying devices, etc., can solve the problems of waste of resources, high cost of waste recycling, pollution of the environment, etc., and achieve the effect of recycling and automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

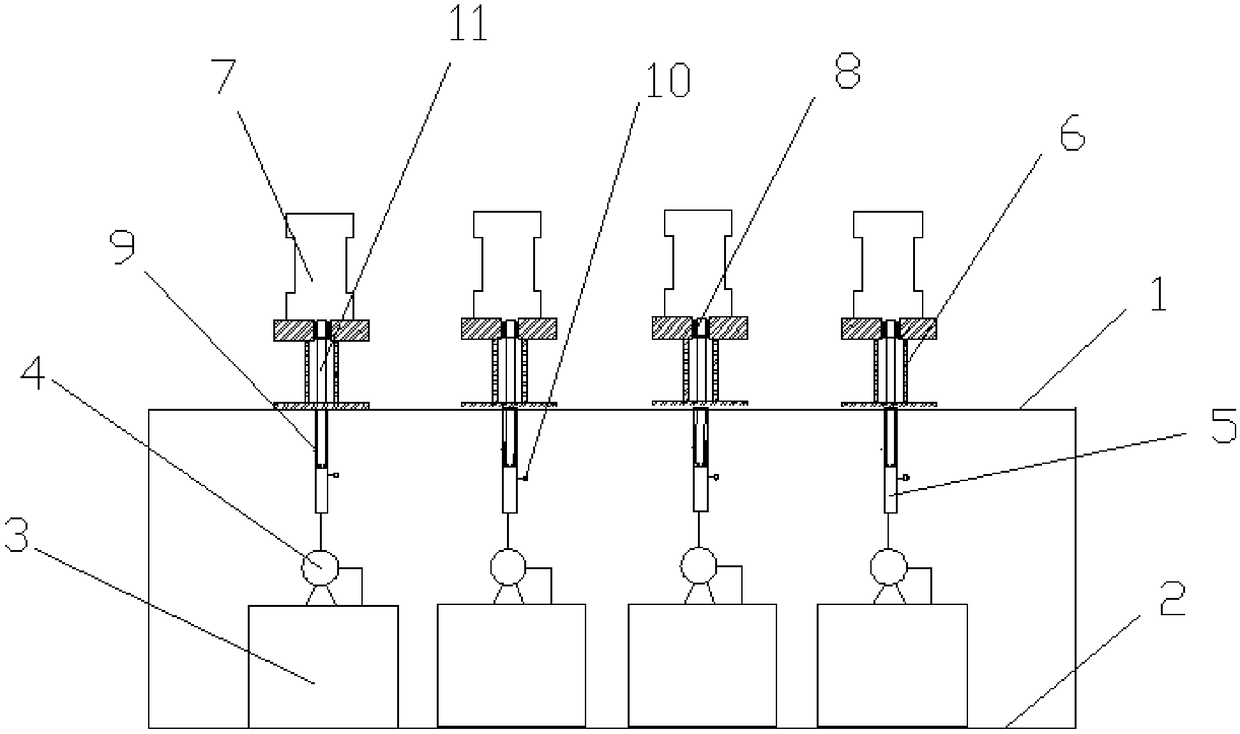

[0022] Please refer to Figure 1 ~ Figure 4 As shown, a fully automatic paint supply device includes a machine base, a paint tank 3 arranged below the machine base, a paint pipe 5 and a paint pump 4, and a paint box arranged above the machine base.

[0023] The machine base includes a bottom plate 2 and a top plate 1 , and an accommodation space is formed between the bottom plate 2 and the top plate 1 .

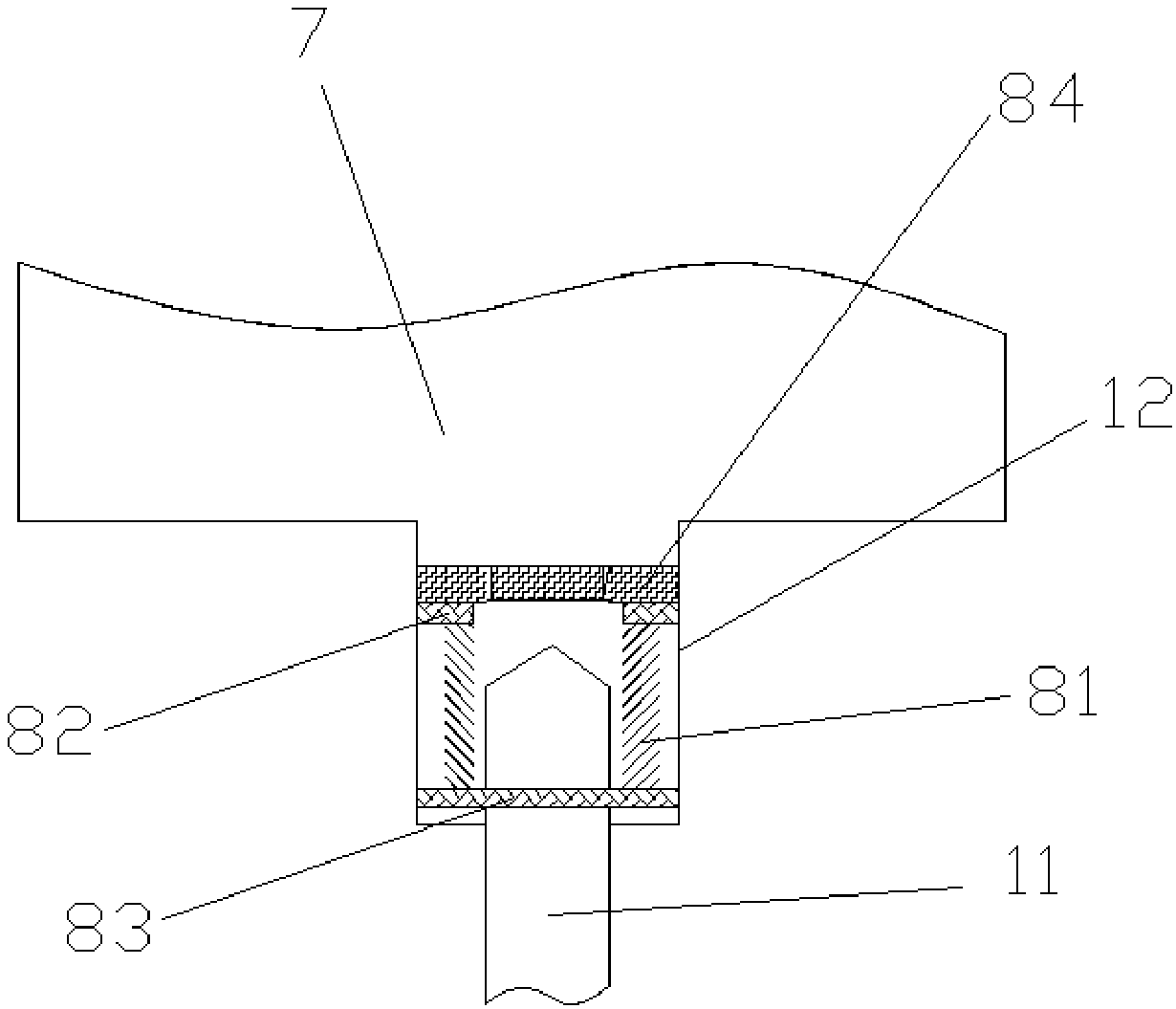

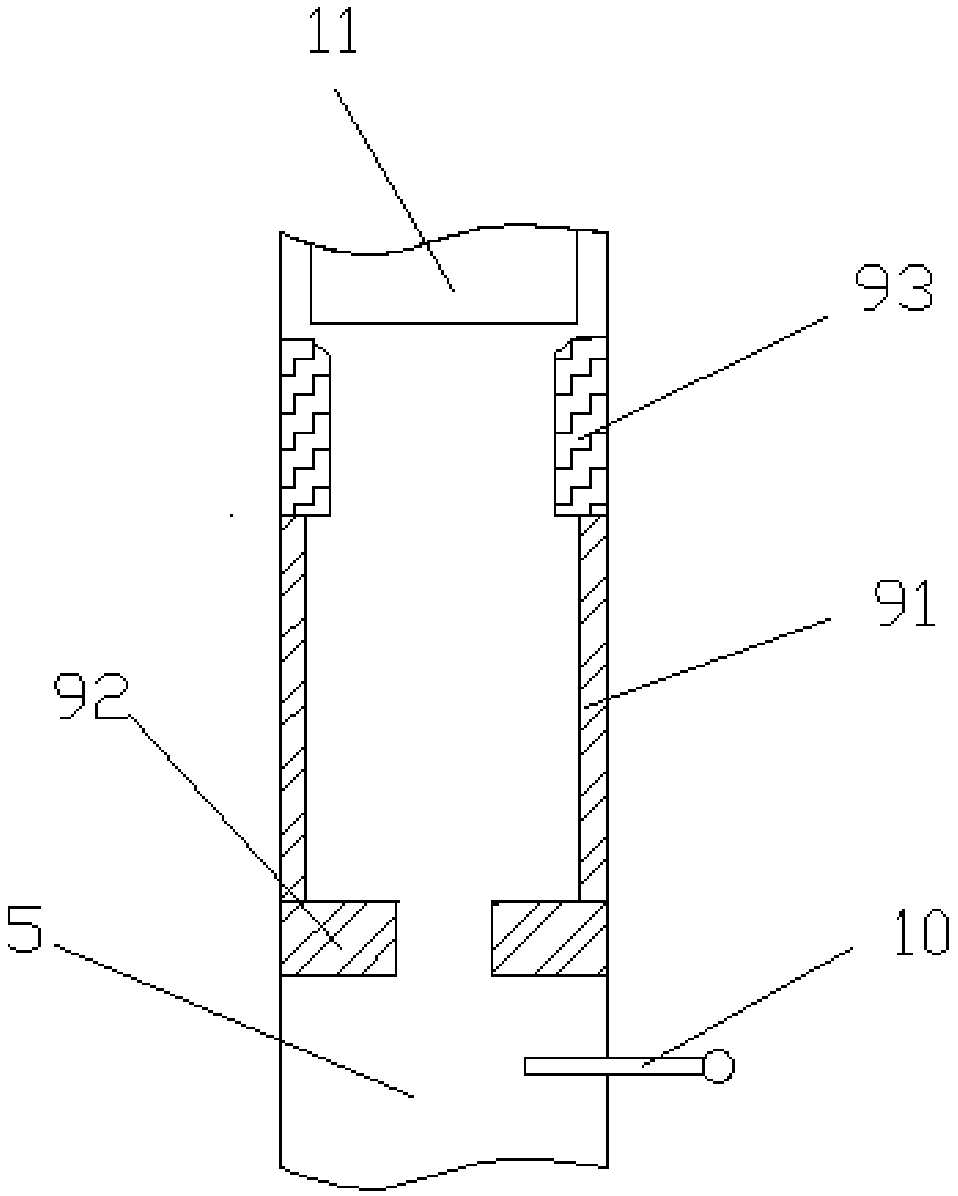

[0024] The base is provided with several support assemblies 6, the support assembly 6 includes a support portion, the center of the support portion is provided with a circular passage, the top of the support portion is provided with a support platform, and the support platform is provided with A central through hole. The diameter of the central through hole is larger than the diameter of the circular channel in the center of the support part. The bottom end of the support part is provided with a connecting part, and the connecting part is connected with the top plate 1 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com