Electron beam welding and superplastic forming process for wing and rudder parts

A technology of electron beam welding and superplastic forming, which is applied in the direction of electron beam welding equipment, welding equipment, non-electric welding equipment, etc., can solve the problem that the quality of the diffusion connection of the core layer is difficult to guarantee, the air flow of the middle core layer is not smooth, and the surface of the part is affected Quality and other issues, to achieve the effect of avoiding solder resist coating work, high cell size accuracy, and reducing the risk of air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

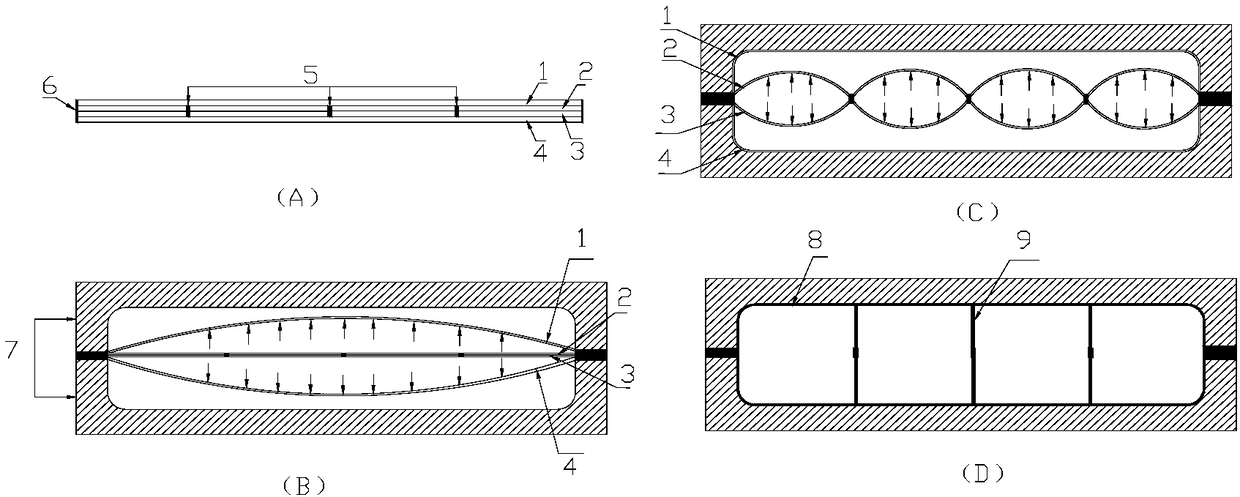

[0034] refer to figure 1 , the wing and rudder parts proposed by the present invention adopt electron beam welding superplastic forming process as follows:

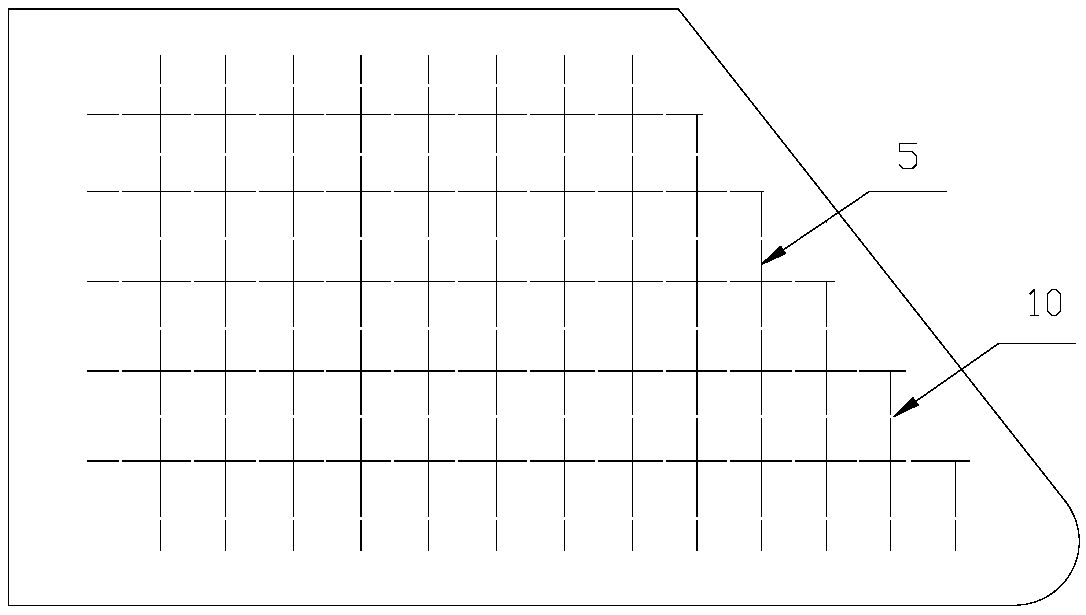

[0035] (1) Cutting the upper core layer 2, the lower core layer 3, the upper skin 1, and the lower skin 4 according to the drawings;

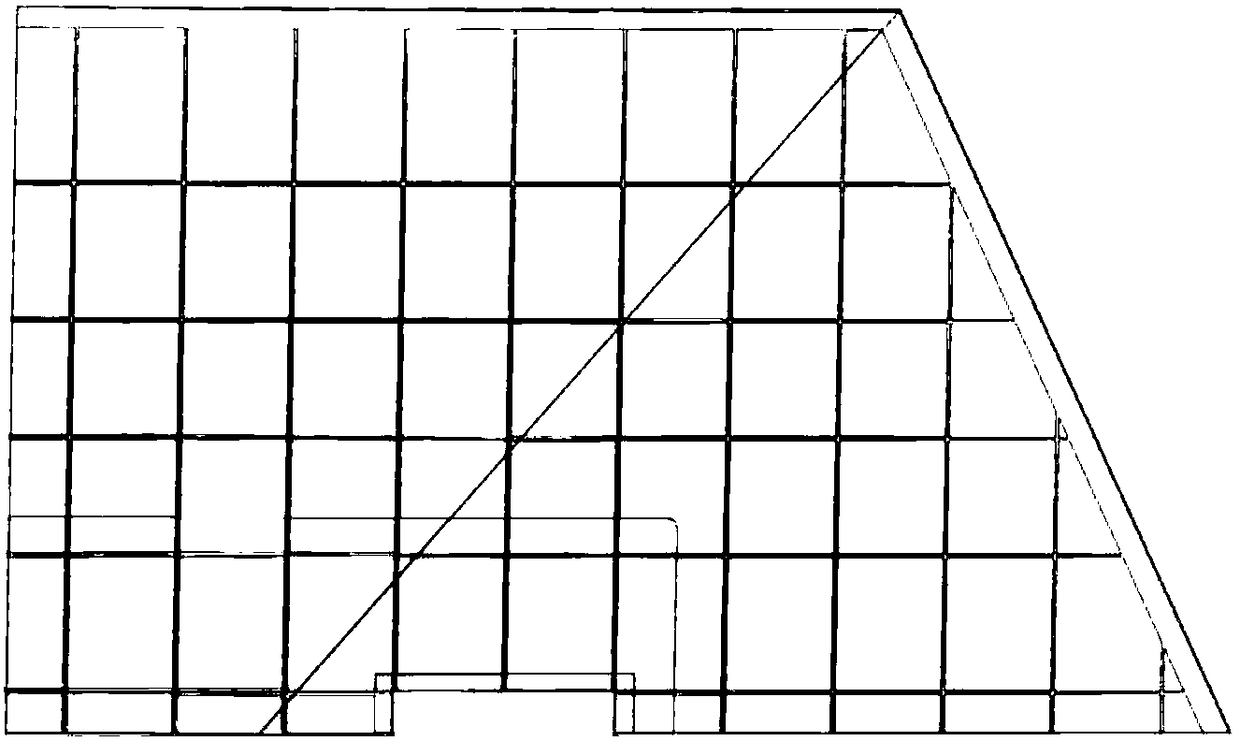

[0036] (2) Add ventilation grooves to the upper core layer 2 and lower core layer 3, and carry out pickling, and carry out electron beam penetration welding on the plates of the upper core layer 2 and lower core layer 3 according to the size distribution of the internal core cells of the wing and rudder parts ;

[0037] (3) manual argon arc welding on the periphery of the upper core layer 2 and the lower core layer 3 (that is, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com