Synthesis method of borate

A synthesis method and borate ester technology are applied in the field of rare earth metal complex catalytic reaction, and achieve the effects of high yield, high reaction efficiency and easy product post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

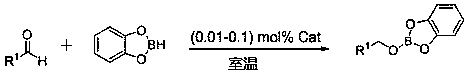

Method used

Image

Examples

Embodiment 1

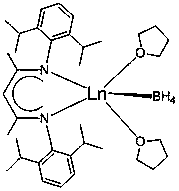

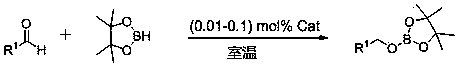

[0031] Embodiment one: [2,6- i pr 2 -(C 6 h 3 )-NC(Me)CHC(Me)N-(C 6 h 3 )-2,6- i pr 2 ] Yb-BH 4 . 2THF Catalyzed Hydroboration of Benzaldehyde and Pinacol Borane

[0032] Add 0.1 mL of catalyst [2,6- i pr 2 -(C 6 h 3 )-NC(Me)CHC(Me)N-(C 6 h 3 )-2,6- i pr 2 ]Yb-BH 4 . 2THF in toluene (0.01 M), then add pinacol borane (0.145 mL, 1 mmol) by syringe, and then add benzaldehyde (0.101 mL, 1 mmol) by syringe. After reacting for 15 min, add 0.5 mL CDCl 3 , the NMR yield was 99%, and then the CDCl was dried under reduced pressure 3 and toluene mixed solution, add n-hexane (3 × 2 mL), and drain to obtain the corresponding pinacol borate, C 6 h 5 CH 2 OB(OC(CH 3 ) 2 C(CH 3 ) 2 O). NMR data of the product:

[0033] 1 H NMR (400 MHz, CDCl 3 ): 7.35−7.29 (m, 4H, Ar H ), 7.27−7.22 (m, 1H, Ar H ),4.92 (s, 2H, ArC H ), 1.25 (s, 12H, C(C H 3 ) 2 ) ppm. 11 B NMR (128 MHz, CDCl 3 ): 25.9ppm.

Embodiment 2

[0034] Embodiment two: [2,6- i pr 2 -(C 6 h 3 )-NC(Me)CHC(Me)N-(C 6 h 3 )-2,6- i pr 2 ] Sm-BH 4 . 2THF Catalyzed Hydroboration of Benzaldehyde and Pinacol Borane

[0035] Add 0.01 mL of catalyst [2,6- i pr 2 -(C 6 h 3 )-NC(Me)CHC(Me)N-(C 6 h 3 )-2,6- i pr 2 ]Sm-BH 4 . 2THF in toluene (0.01 M), then add 0.09 mL of toluene by syringe, then add pinacol borane (0.145 mL, 1 mmol) by syringe, and then add benzaldehyde (0.101 mL, 1 mmol) by syringe, reaction 15 After min, add 0.5 mL CDCl 3 , the NMR yield was 90%, and then the CDCl was dried under reduced pressure 3 and toluene mixed solution, and to remove unreacted aldehyde, add n-hexane (3 × 2 mL), and drain to obtain the corresponding pinacol borate, C 6 h 5 CH 2 OB(OC(CH 3 ) 2 C(CH 3 ) 2 O). The NMR data of the product are the same as in Example 1.

Embodiment 3

[0036] Embodiment three: [2,6- i pr 2 -(C 6 h 3 )-NC(Me)CHC(Me)N-(C 6 h 3 )-2,6- i pr 2 ] Sm-BH 4 . 2THF Catalyzed Hydroboration of Benzaldehyde and Pinacol Borane

[0037] Add 0.05 mL of catalyst [2,6- i pr 2 -(C 6 h 3 )-NC(Me)CHC(Me)N-(C 6 h 3 )-2,6- i pr 2 ]Sm-BH 4 . 2 THF in toluene (0.01 M), then 0.05 mL of toluene was added by syringe, then pinacolborane (0.145 mL, 1 mmol) was added by syringe, and benzaldehyde (0.101 mL, 1 mmol) was added by syringe. After reacting for 10 min, add 0.5 mL CDCl 3 , the NMR yield was 94%, and then the CDCl was dried under reduced pressure 3 Mixed solution with toluene and remove unreacted aldehyde, add n-hexane (3 × 2 mL), and drain to obtain the corresponding pinacol borate, C 6 h 5 CH 2 OB(OC(CH 3 ) 2 C(CH 3 ) 2 O). The NMR data of the product are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com