Blow-molded PC/ABS composite material with high heat resistance and high melt strength and preparation method therefor

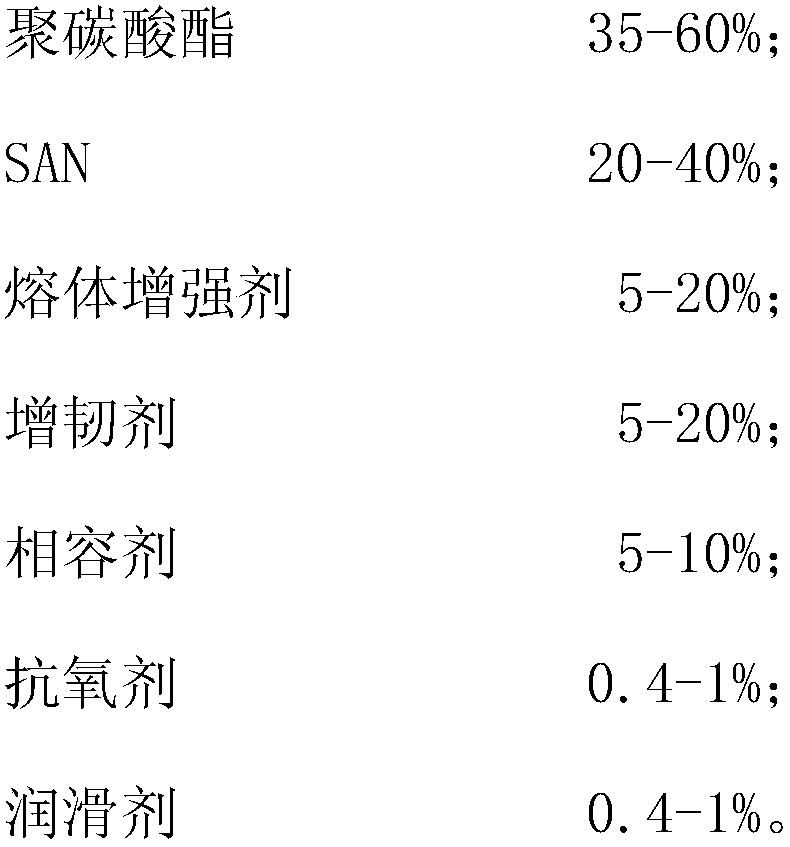

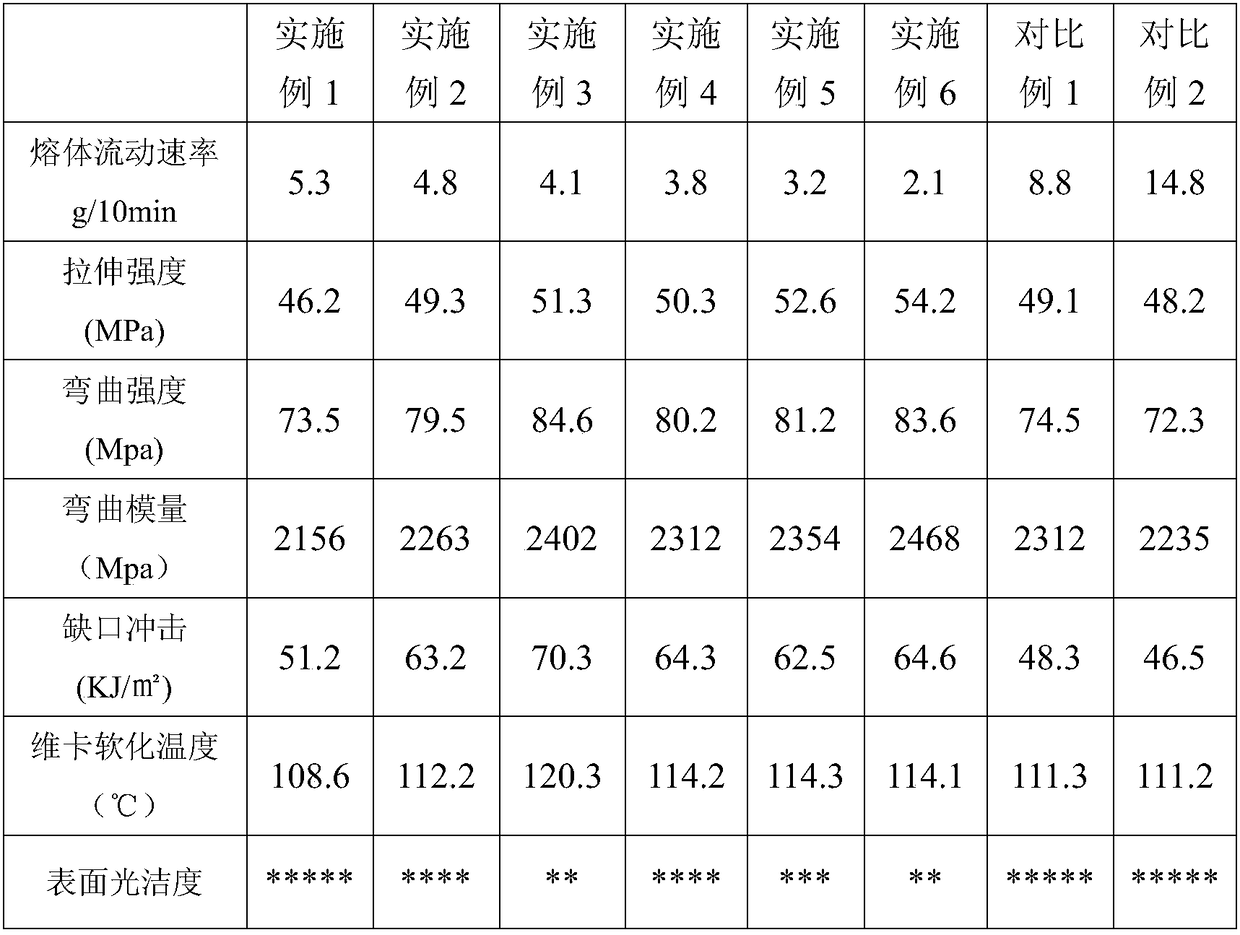

A technology of high melt strength and composite materials, which is applied in the field of high melt strength blow molding PC/ABS composite materials and high heat resistance. High impact performance and other issues, to achieve the effect of uniform product thickness, improved melt strength, and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below through specific examples, but the examples are only used to illustrate the present invention rather than limit the present invention.

[0023] Raw materials used in the present invention:

[0024] Polycarbonate-1: produced by Luxi, PC-LXTY1603;

[0025] Polycarbonate-2: produced by LG, PC-201-10;

[0026] SAN: produced by Zhenjiang Chimei, PN-138H;

[0027] Melt enhancer: produced by Kumho Petrochemical, P-2500;

[0028] Toughener: ABS high-glue powder, model HR-181, 60% glue content, Korea Kumho;

[0029] Compatibilizer: DOW chemical production, MBS-2616;

[0030] Antioxidant 1010: hindered phenolic antioxidant, produced by DOUBLE BOND CHEMICAL IND. Co., Ltd.;

[0031] Antioxidant 619F: phosphite auxiliary antioxidant, produced by Chemtura;

[0032] Lubricant KJ-A01: Silicone masterbatch produced by Kaijie;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com