Pyrolysis reaction device applied to medical waste pyrolysis treatment system

A medical waste and processing device technology, which is applied in the preparation of liquid hydrocarbon mixtures, special forms of dry distillation, petroleum industry, etc., can solve the problems of incomplete treatment of medical waste, inability to recycle heat, energy loss, etc., and achieve thorough treatment and saving Effects of energy and fertile soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

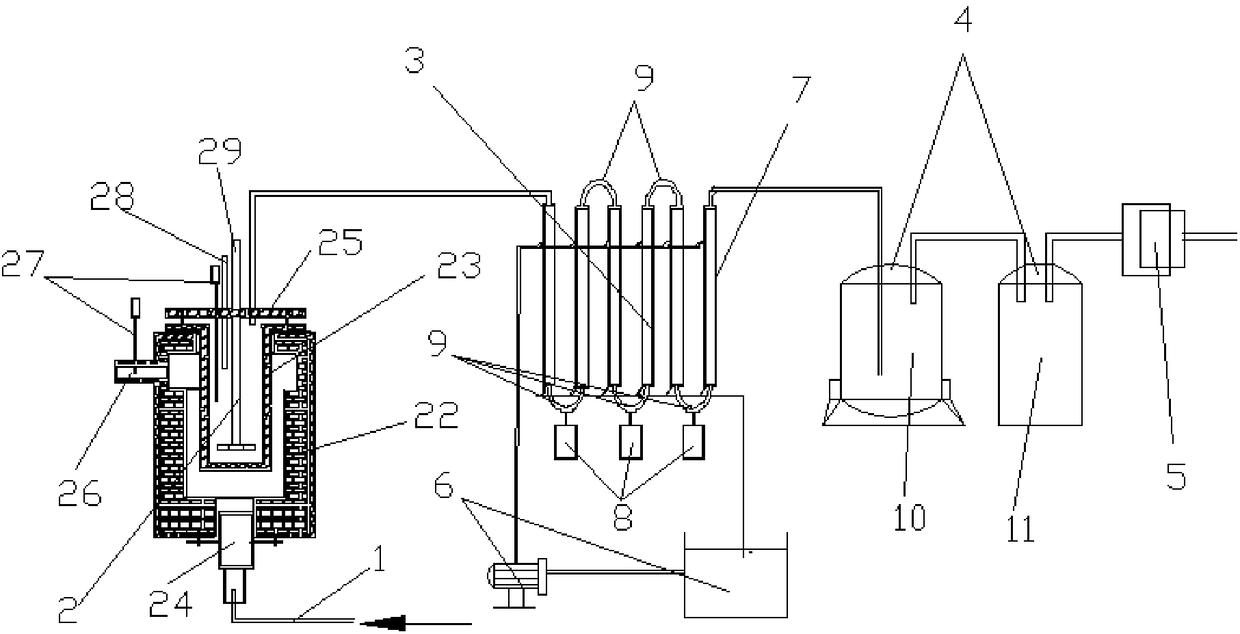

[0023] Such as figure 1 As shown, a medical waste pyrolysis treatment device includes an electric control cabinet, a gas supply system for providing gas and combustion-supporting air, and a pyrolysis reaction device 2 for pyrolyzing medical waste, which are connected successively through pipelines. The cooling system 3 for cooling the pyrolysis gas, the gas absorption device for absorbing the acid gas in the pyrolysis gas, and the pyrolysis gas combustion device 5 .

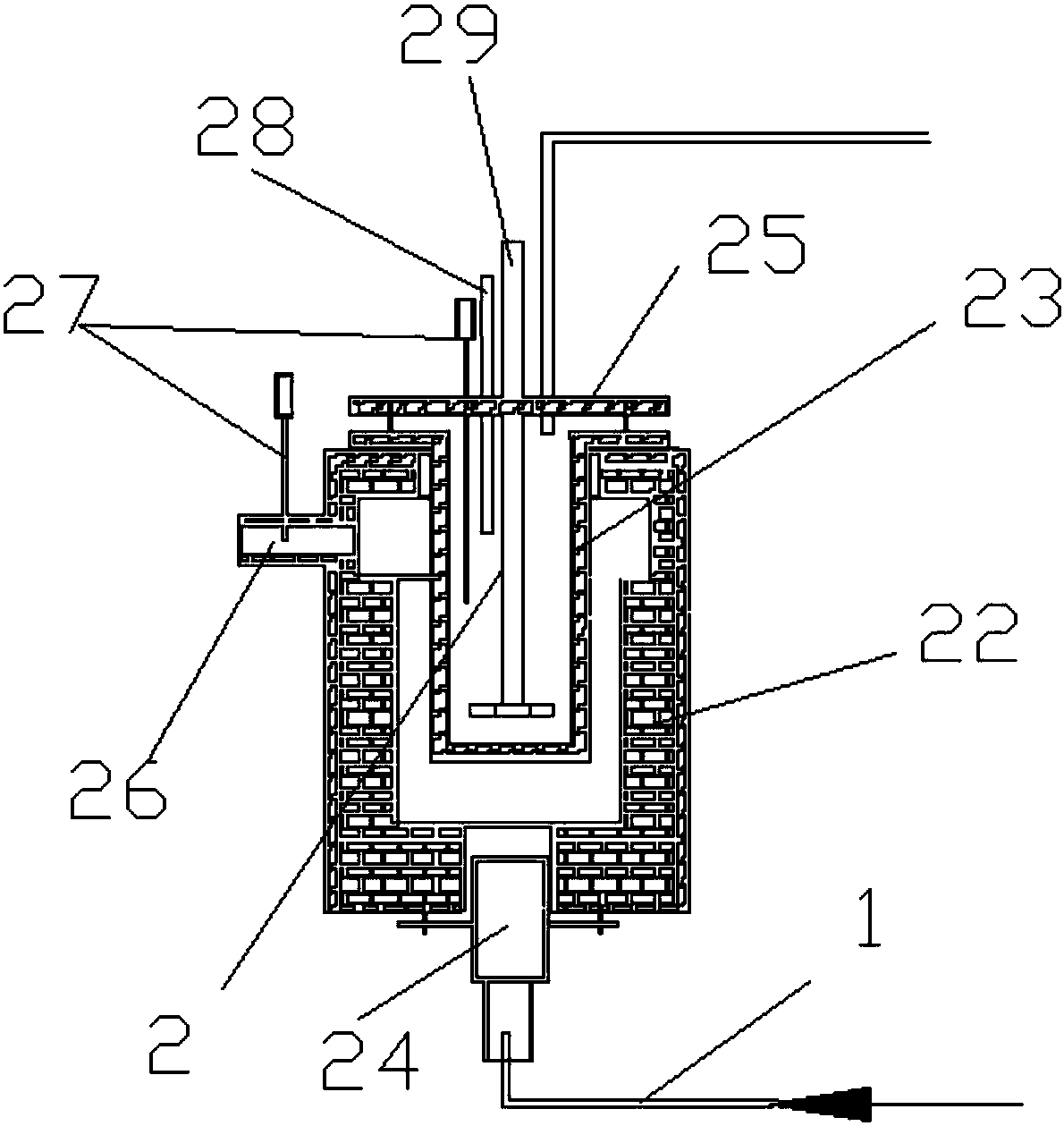

[0024] Such as figure 2 As shown, the pyrolysis reaction device 2 includes a burner 24 , a heating furnace body 22 , a pyrolysis reactor 23 , a steam generator and a cover plate 25 . The inside of the heating furnace body 22 is provided with a combustion cavity, and the bottom and top of the heating furnace body 22 are respectively provided with openings leading to the combustion cavity, and the burner 24 is arranged at the opening at the bottom of the heating furnace body 22. The pyrolysis reactor 23 is put i...

Embodiment 2

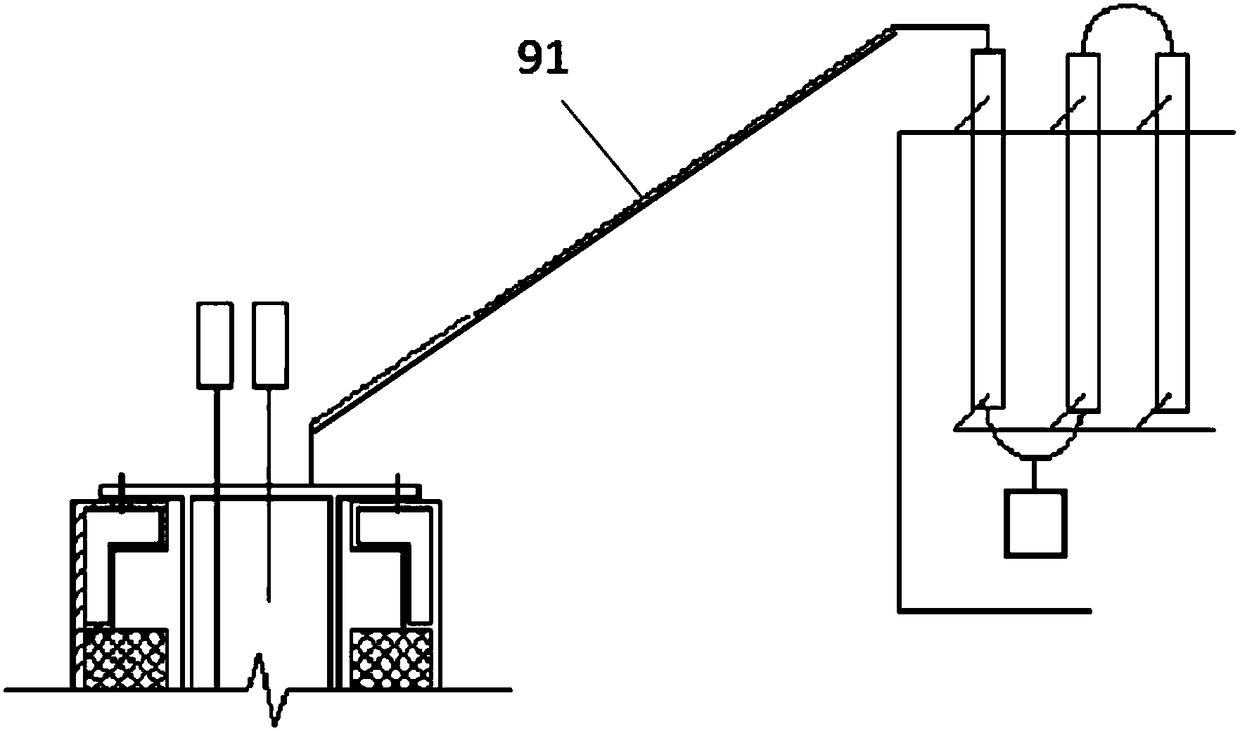

[0031] Such as image 3 As shown, it is a structural diagram of the improvement of embodiment 2 to the arrangement of pipelines between the pyrolysis reaction device 2 and the cooling system 3 of embodiment 1. Since the pyrolysis gas is transported from the pyrolysis reaction device 2 to the cooling system 3 through the pipeline, the tar in the pyrolysis gas will accumulate in the delivery pipeline, which affects the transmission efficiency of the pyrolysis gas. Therefore, the pipeline between the pyrolysis reaction device 2 and the cooling system 3 is arranged obliquely, and the tar flows back into the pyrolysis reactor 23 through the inclined pipeline. At the same time, a heating belt is arranged on the connecting pipeline between the pyrolysis reaction device and the cooling system, and the pyrolysis gas will also be cooled to a certain extent when the pipeline between the pyrolysis reaction device and the cooling system is transported. If the pipeline is too long, the tar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com