A system for extracting special solvent oil from stable light hydrocarbons

A technology for stabilizing light hydrocarbons and solvent oils, applied in the field of oil refining and chemical industry, can solve problems affecting the operation of reforming units and liquid mass yield, affect the mass yield of trienes, and fail to achieve separation accuracy, so as to reduce the severity of operation , Improve product quality, good product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

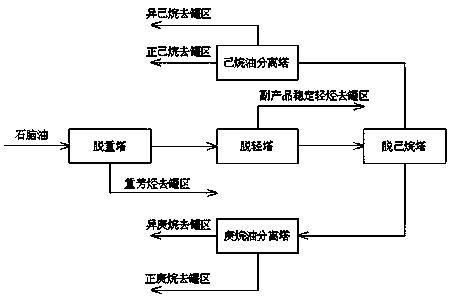

[0038] Such as figure 1 As shown, the present embodiment provides a method for extracting special solvent oil from stable light hydrocarbons, including:

[0039] S1: Send the raw material stable light hydrocarbons to the weight removal tower, after being separated by the weight removal tower, condense at the top of the weight removal tower to obtain light component oil, and obtain heavy aromatics at the bottom of the weight removal tower, among which, the top of the weight removal tower The operating temperature is 70°C and the operating pressure is 100KPa, and the operating temperature at the bottom of the weight removal tower is 140°C and the operating pressure is 155KPa;

[0040] S2: Send the light component oil into the light removal tower, after being separated by the light removal tower, condense at the top of the light removal tower to obtain stable light hydrocarbons as by-products, and obtain C at the bottom of the light removal tower 6 -C 7 Components, wherein the ...

Embodiment 2

[0061] This embodiment provides a method for extracting special solvent oil from stable light hydrocarbons, including:

[0062] S1: Send the raw material stable light hydrocarbons to the weight removal tower, after being separated by the weight removal tower, condense at the top of the weight removal tower to obtain light component oil, and obtain heavy aromatics at the bottom of the weight removal tower, among which, the top of the weight removal tower The operating temperature is 74.5°C and the operating pressure is 105KPa, and the operating temperature at the bottom of the weight removal tower is 145.4°C and the operating pressure is 160KPa;

[0063] S2: Send the light component oil into the light removal tower, after being separated by the light removal tower, condense at the top of the light removal tower to obtain stable light hydrocarbons as by-products, and obtain C at the bottom of the light removal tower 6 -C 7 Components, wherein the operating temperature at the to...

Embodiment 3

[0072] This embodiment provides a method for extracting special solvent oil from stable light hydrocarbons, including:

[0073] S1: Send the raw material stable light hydrocarbons to the weight removal tower, after being separated by the weight removal tower, condense at the top of the weight removal tower to obtain light component oil, and obtain heavy aromatics at the bottom of the weight removal tower, among which, the top of the weight removal tower The operating temperature is 80°C and the operating pressure is 110KPa, and the operating temperature at the bottom of the weight removal tower is 150°C and the operating pressure is 165KPa;

[0074] S2: Send the light component oil into the light removal tower, after being separated by the light removal tower, condense at the top of the light removal tower to obtain stable light hydrocarbons as by-products, and obtain C at the bottom of the light removal tower 6 -C 7 Components, wherein the operating temperature at the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com