Method of producing ultralow phosphoretic steel by extra furnace dephosphorization of molten steel

A technology for dephosphorization and ultra-low phosphorus steel outside the furnace, applied in the field of steel smelting, can solve the problems of large fluctuation of phosphorus content at the end of molten steel, difficulty in rapidly forming high basicity slag, and difficulty in producing low phosphorus steel, etc. Achieving good dephosphorization rate, reducing dephosphorization burden and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for producing ultra-low phosphorus steel by dephosphorizing molten steel outside the furnace, the method comprising the following steps:

[0023] 1. Converter smelting for vanadium extraction

[0024] 2. Semi-steel tapping: after the smelting of the vanadium extraction converter is completed, the steel is tapped at a temperature ≥ 1350 °C and a carbon content ≥ 3.3%;

[0025] When tapping, the slag is used to tap the steel, and argon is blown throughout the tapping process;

[0026] Put the special flux for dephosphorization outside the furnace of semi-steel into the ladle at one time when 1 / 3 of the semi-steel is tapped, the amount of special flux for dephosphorization outside the furnace of semi-steel is 6.5-10kg / t The composition of lime is 35-45%, iron oxide 40-50%, fluorite 10-15%, industrial soda ash 5-10%;

[0027] After adding the dephosphorization flux, continue to tap until the end;

[0028] 3. Desulfurization: desulfurize after removing the slag a...

Embodiment 2

[0039] This embodiment is basically the same as Embodiment 1, the difference is that the composition of the special flux for dephosphorization outside the semi-steel furnace in this embodiment is 40% lime, 45% iron oxide, 10% fluorite, and 5% industrial soda ash. The dephosphorization effect is shown in Table 1.

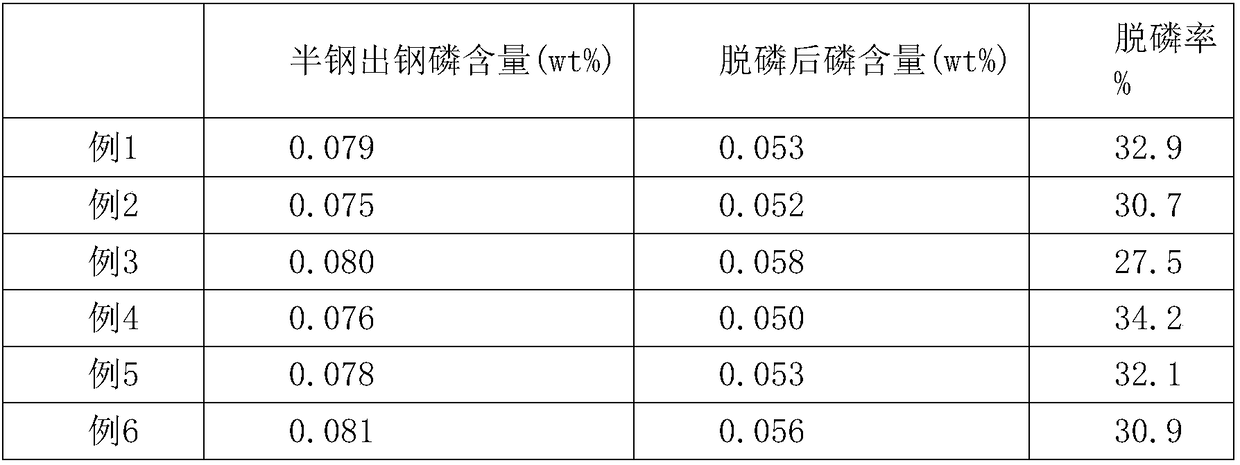

[0040]

[0041] Example 1 and Example 6 are different experiments. Due to the influence of various factors, the composition of each furnace semi-steel produced by the steel factory is not completely consistent.

[0042] As can be seen from Table 1, adopting the method of the present invention can obtain considerable dephosphorization effect without increasing procedures and time, and the present invention utilizes the dephosphorization in the semi-steel tapping process to reduce the consumption of conventional converter dephosphorization flux , shorten the dephosphorization treatment time of the conventional converter, easy to use, high dephosphorization efficienc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com