Novel graphite boat

A graphite boat, a new type of technology, applied in gaseous chemical plating, coating, electrical components and other directions, can solve the problems of affecting the pass rate and output, easy warping, radio frequency alarm, etc., to improve the pass rate and output, reduce Chromatic aberration, reducing the effect of warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Objects, advantages and features of the present invention will be illustrated and explained by the following non-limiting description of preferred embodiments. These embodiments are only typical examples of applying the technical solutions of the present invention, and all technical solutions formed by adopting equivalent replacements or equivalent transformations fall within the protection scope of the present invention.

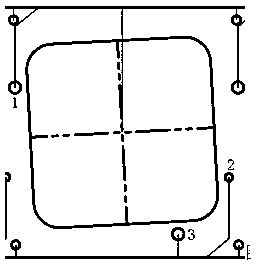

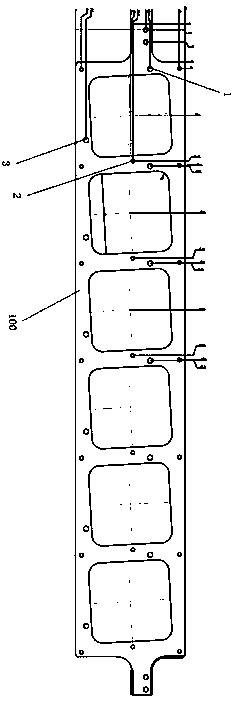

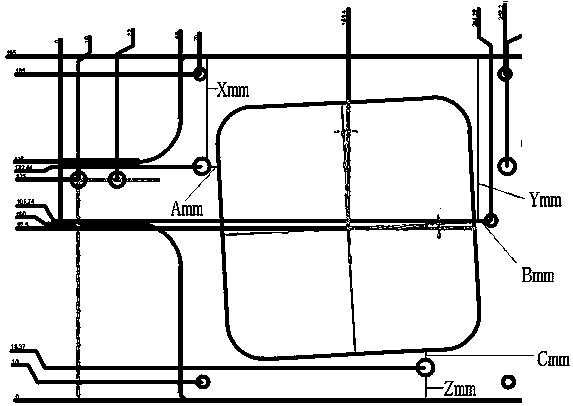

[0021] The present invention discloses a novel graphite boat, such as figure 2 As shown, the graphite boat includes at least 8 graphite boat blades, which are respectively the first graphite boat blade 100, the second graphite boat blade, the third graphite boat blade, the fourth graphite boat blade, the fifth graphite boat blade, the sixth graphite boat blade A graphite boat blade, a seventh graphite boat blade, and an eighth graphite boat blade.

[0022] The first graphite boat blade and the eighth graphite boat blade are the outermost graphite b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com