Well sealing method and well sealing device for ultrahigh-layer high-water-pressure deep precipitation well

A deep well dewatering and high water pressure technology, applied in construction, infrastructure engineering, etc., can solve the problems of high impact force of water glass glue, poor sealing durability, water glass glue splashing, etc., and achieve low cost of well sealing and environmental performance High, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

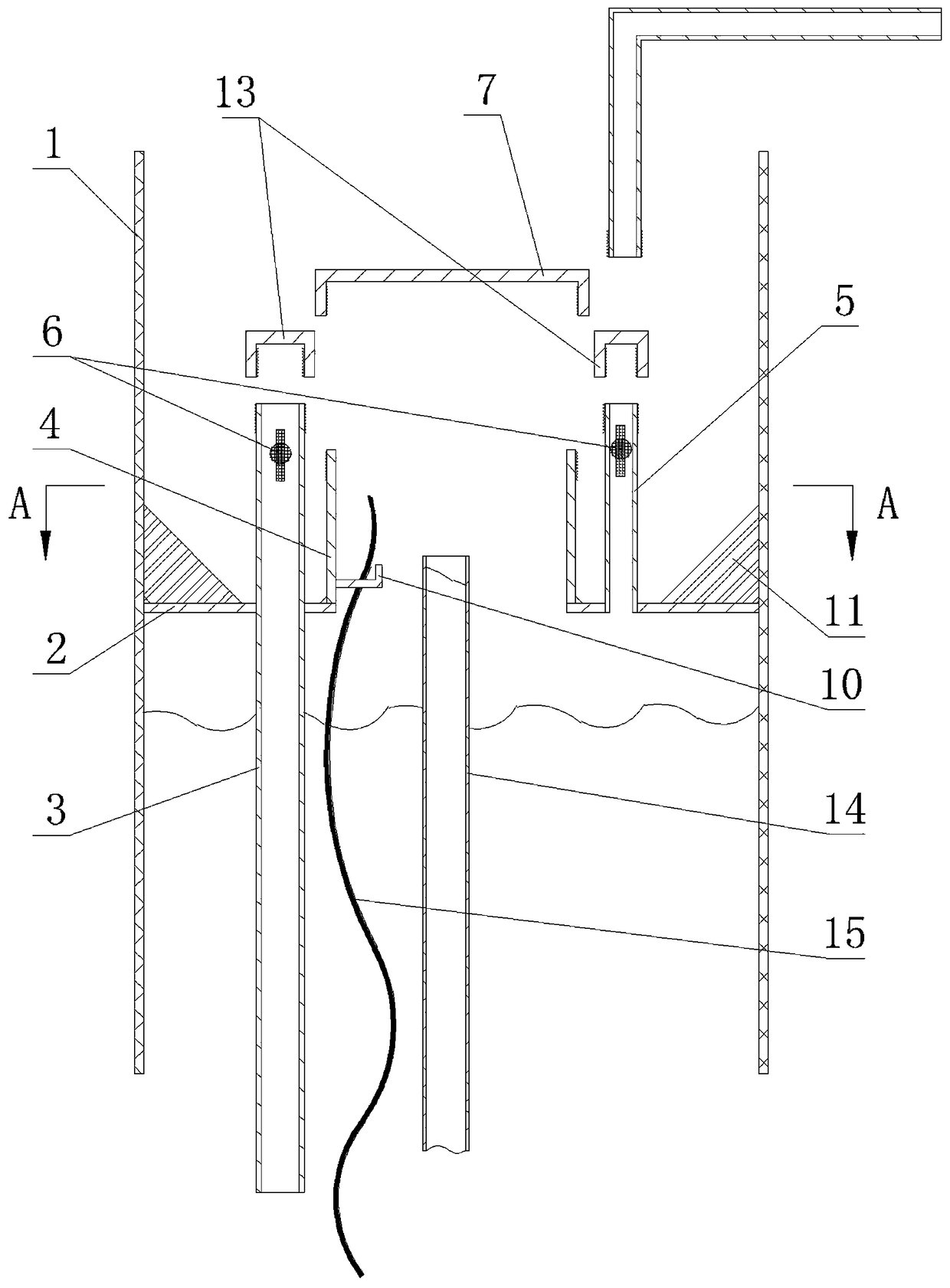

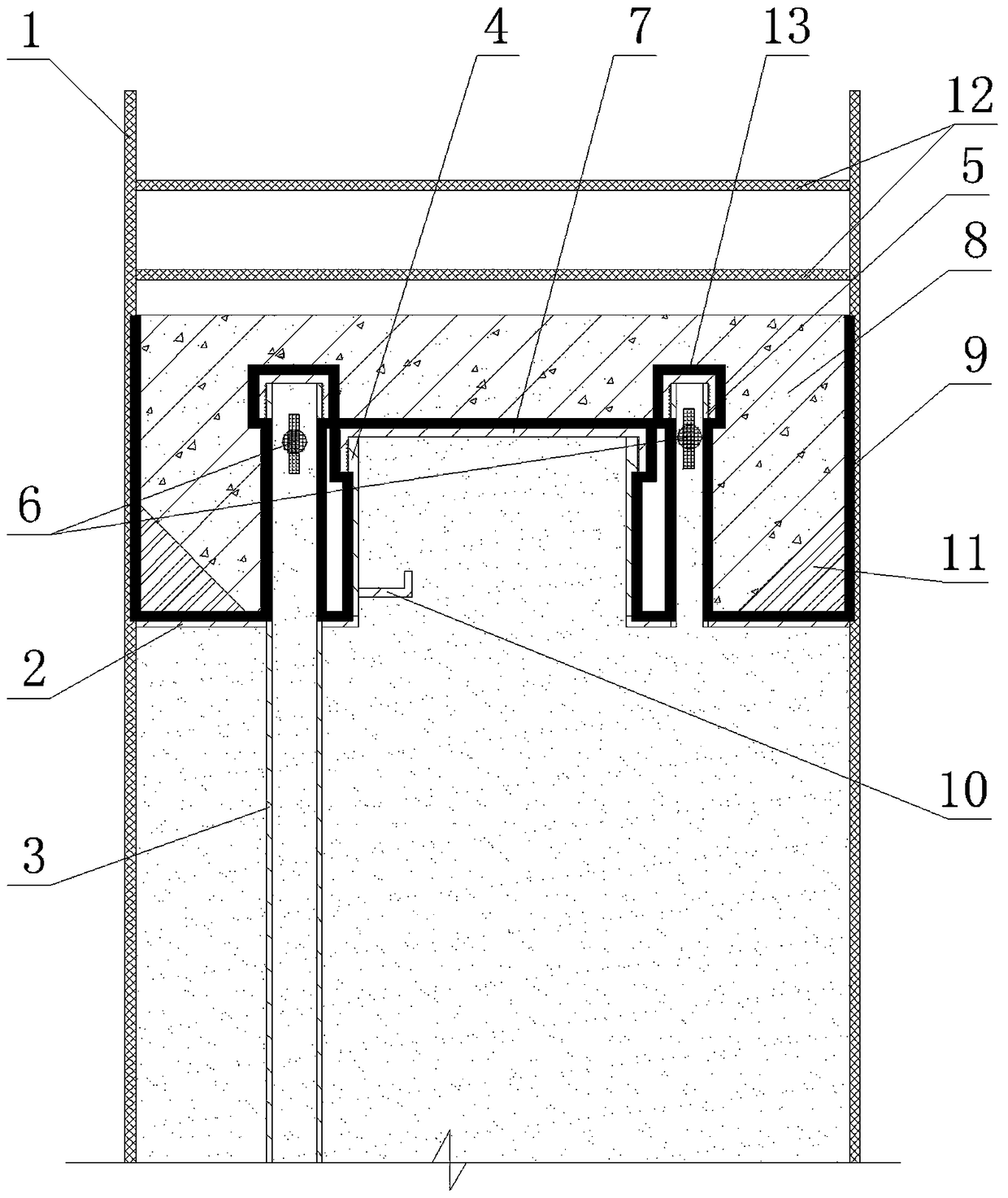

[0037] This method of closing the well of the present invention for super high-rise high water pressure deep well dewatering well comprises the following steps:

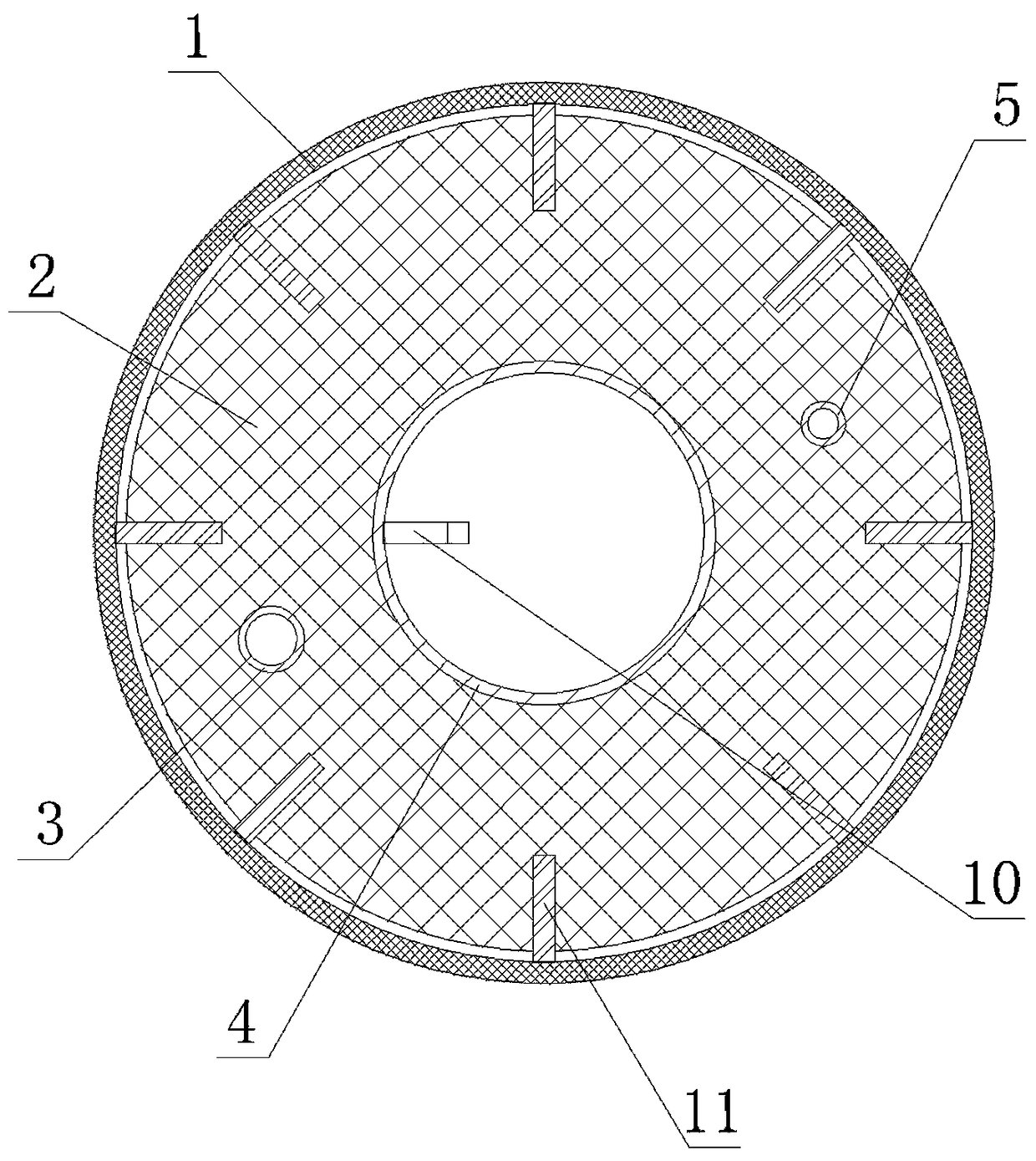

[0038] (1) Make a water sealing plate according to the inner diameter of the dewatering well, open three through holes on the water sealing plate and seamlessly weld grouting pipes, drainage pipes and casings of specified length;

[0039] (2) Set the water sealing plate on the pumping hose of the submersible pump through the casing, put the submersible pump into the dewatering well for pumping operation, and ensure that the pumping rate of the submersible pump is greater than the rate of rise of the water level in the dewatering well;

[0040] (3) When the water level in the dewatering well drops to at least 450mm from the wellhead, while the submersible pump is pumping water to lower the water level, use a hair dryer to dry the steel casing at the welding point, and then dry the steel casing in step (1). The sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com