Slideway type slide sheet for module and use method thereof

A technology of sliding rail and sliding vane, which is applied in the direction of linear motion bearings, centrifugal force-resistant rotating parts, bearings, etc., can solve the problems of large vibration and noise, low bearing capacity, etc., and achieve low cost, large bearing capacity, The effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

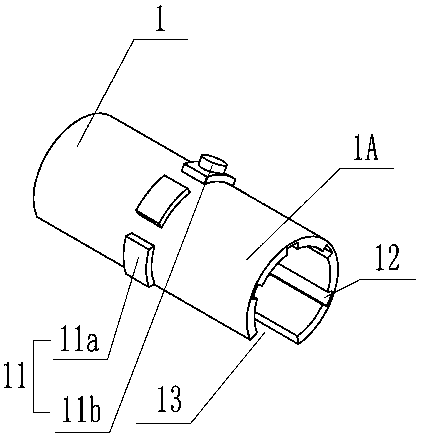

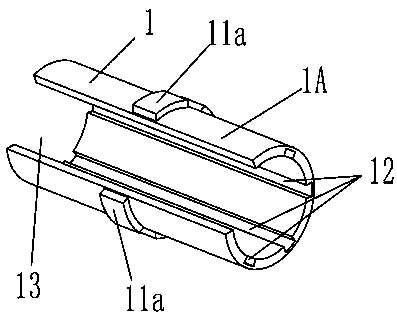

[0053] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the slide rail type slider 1 for the module includes a cylindrical slider body 1A, the outer wall of the slider body 1A is provided with a mounting structure 11 corresponding to the slider 2, and the inner wall is provided with a row Chip flute12.

[0054] The outer wall of the slider main body 1A is used to fix the slider 2, so that the slider 1 and the slider 2 remain relatively fixed, and the inner cavity of the slider main body 1A is used to pass through the guide rail 3, so that the slider 2 is stable on the guide rail 3 Sliding, the surface contact between the guide rail 3 and the slider 2, the load borne by the slider 2 is directly transmitted to the guide rail 3 through the slider 1, so the bearing capacity is large, and there will be no greater vibration or vibration during high-speed movement noise.

[0055] In addition, by setting up chip removal grooves 12 on the inner wall of the slide bod...

Embodiment 2

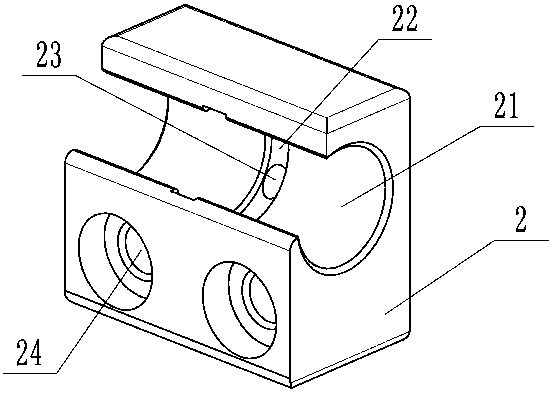

[0071] Such as Figure 4 As shown, the method of using the slide-rail slide, when using the slide-rail slide for the module as described above, the operation steps are as follows:

[0072] a. Install the slider 1, install the slider 1 into the chute 21 of the slider 2, and keep the slider 1 and the slider 2 relatively fixed;

[0073] b. Install the slider 2, assemble the guide rail 3 and the slider 2, and make the track 31 of the guide rail 3 pass through the chute 21;

[0074] c. Fix the guide rail 3, and fix the guide rail 3 on the support platform through the installation hole 32 provided on the guide rail 3;

[0075] d. Install the load component and assemble the load component on the slider 2 .

[0076] Embed the slider 1 between the guide rail 3 and the slider 2, so that the slider 1 and the slider 2 form an assembled integral structure, and rely on the support of the slider 1, so that the slider 2 can smoothly move on the guide rail by sliding friction. 3, avoiding f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com