Aluminum foil used for lithium ion battery, microporous aluminum foil and preparation method thereof

A lithium-ion battery and aluminum foil technology, which is applied in the manufacture of electrodes, battery electrodes, chemical electrodes, etc., can solve the problems of reducing the contact resistance of aluminum oxide foil and reducing the mechanical strength of aluminum foil, so as to improve the activity of lithium ions, elongation, and resistance. The effect of rate increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

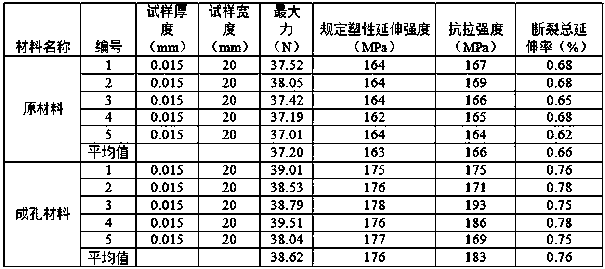

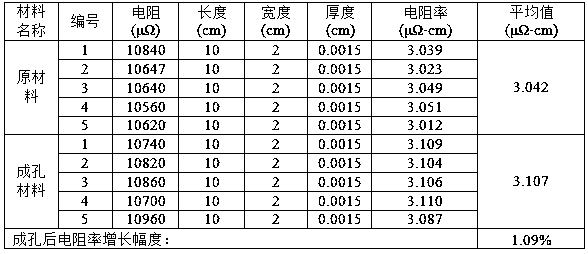

[0027] An aluminum foil for a lithium ion battery, comprising: comprising: 0.16wt% of Mg, 0.08wt% of Si, 0.2wt% of Fe, 0.03wt% of Ga, 0.04wt% of Cu, 0.04wt% of Zn, 0.05wt% % V, 0.03wt% Ti, 99.7wt% aluminum, and the rest are impurities; its resistivity is 3μΩ•m. The aluminum foil is prepared into a microporous aluminum foil through the method for preparing a microporous aluminum foil for a lithium battery.

[0028] A microporous aluminum foil for a lithium battery, comprising: 0.16wt% of Mg, 0.08wt% of Si, 0.2wt% of Fe, 0.03wt% of Ga, 0.04wt% of Cu, 0.04wt% of Zn, 0.05wt% V, 0.03wt% of Ti, 99.7wt% of aluminum, and the rest are impurities.

[0029] The microporous aluminum foil is distributed with 2000-6000 through holes and blind holes with a diameter of 6-12 μm per square centimeter, and the proportion of through holes is 55%; the upper and lower surfaces of the microporous aluminum foil are distributed with multiple nicks , the notch is 1-3 μm deep, 1-5 μm wide, and 100-100...

Embodiment 2

[0047] An aluminum foil for a lithium ion battery, comprising: comprising: 0.18wt% of Mg, 0.05wt% of Si, 0.1wt% of Fe, 0.02wt% of Ga, 0.03wt% of Cu, 0.03wt% of Zn, 0.04wt% % V, 0.01wt% Ti, and 99.7wt% aluminum, and the rest are impurities; its resistivity is 2.5μΩ•m. The aluminum foil is prepared into a microporous aluminum foil through the method for preparing a microporous aluminum foil for a lithium battery.

[0048] A microporous aluminum foil for lithium batteries, comprising: 0.18wt% of Mg, 0.05wt% of Si, 0.1wt% of Fe, 0.02wt% of Ga, 0.03wt% of Cu, 0.03wt% of Zn, 0.04wt% V, 0.01wt% of Ti, 99.7wt% of aluminum, and the rest are impurities.

[0049] The microporous aluminum foil is distributed with 300-2000 through holes and blind holes with a diameter of 6-12 μm per square centimeter, of which the proportion of through holes is 60%; the upper and lower surfaces of the microporous aluminum foil are distributed with multiple nicks , the notch is 1-3 μm deep, 1-5 μm wide, a...

Embodiment 3

[0058] An aluminum foil for a lithium ion battery, comprising: comprising: 0.17wt% of Mg, 0.07wt% of Si, 0.05wt% of Fe, 0.01wt% of Ga, 0.03wt% of Cu, 0.02wt% of Zn, 0.02wt% % V, 0.02wt% Ti, 99.7wt% aluminum, and the rest are impurities; its resistivity is 2μΩ•m. The aluminum foil is prepared into a microporous aluminum foil through the method for preparing a microporous aluminum foil for a lithium battery.

[0059] A microporous aluminum foil for lithium batteries, comprising: 0.17wt% of Mg, 0.07wt% of Si, 0.05wt% of Fe, 0.01wt% of Ga, 0.03wt% of Cu, 0.02wt% of Zn, 0.02wt% V, 0.02wt% of Ti, 99.7wt% of aluminum, and the rest are impurities.

[0060] The microporous aluminum foil is distributed with 500-1000 through holes and blind holes with a diameter of 6-12 μm per square centimeter, and the proportion of through holes is 70%; the upper and lower surfaces of the microporous aluminum foil are distributed with multiple nicks , the notch is 1-3 μm deep, 1-5 μm wide, and 100-10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com