Rail traffic cable connecting assembly with built-in piezoresistors

A technology of rail transit cables and varistors, which is applied to parts, connections, electrical components, etc. Beautiful, guaranteed strength, not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

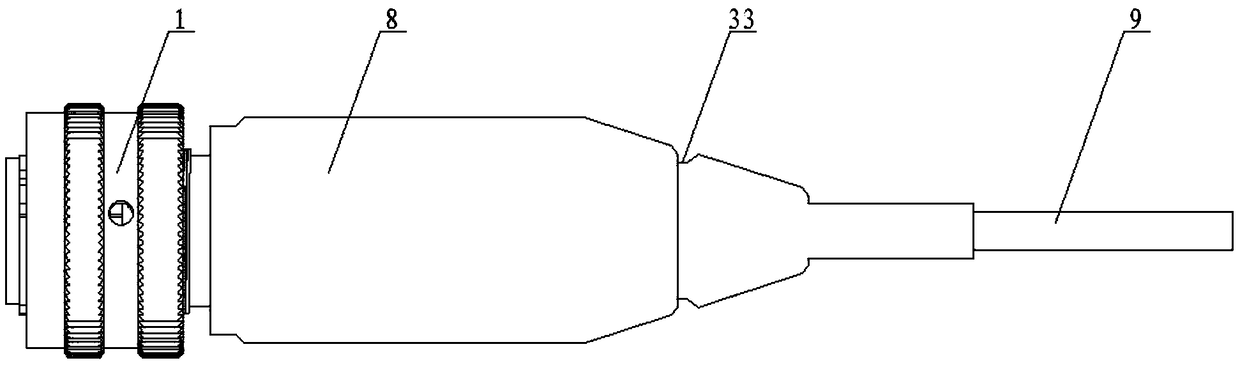

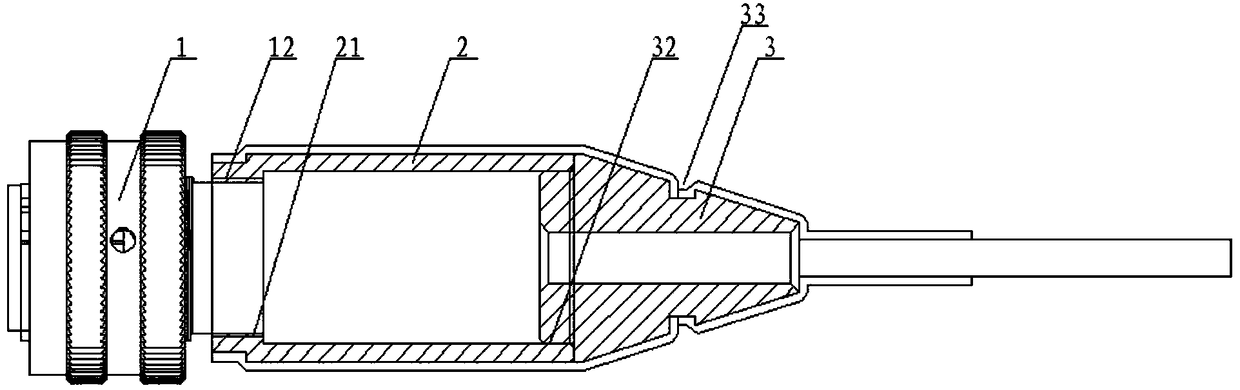

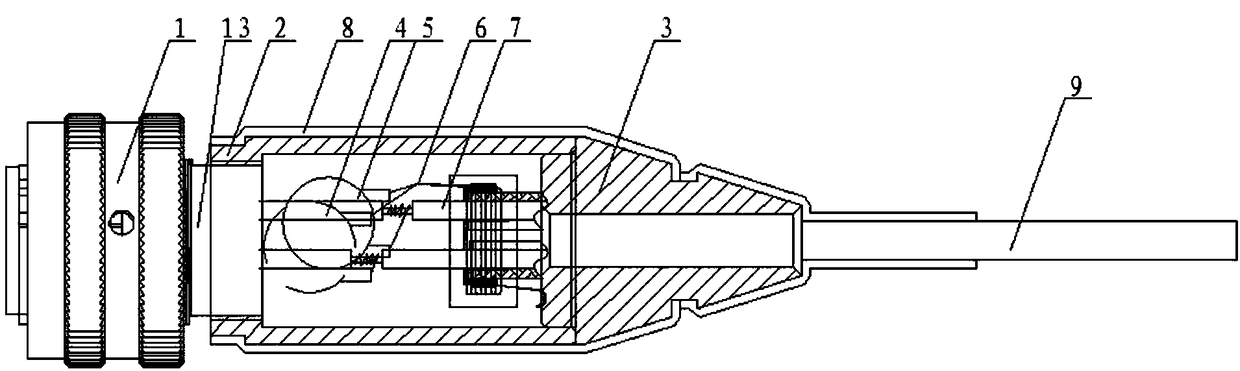

[0029] to combine Figure 1 to Figure 6 As shown, the rail transit cable connection assembly with a built-in varistor in the present invention includes a connector 1, a cable 9 and a varistor 4 (5), and the varistor is connected to the line where the cable 7 is electrically connected to the connecting terminal of the connector 1 superior;

[0030] It also includes a tube and shell assembly, which includes a tail cover 2, a tail shell 3 and a heat shrinkable tube 8;

[0031] The tail cover 2 is a hollow cylinder, and the inside of the tail shell 3 is provided with a wire hole 31 coaxial with the inner cavity of the tail cover 2; one end of the tail cover 2 is detachably connected to the connector 1, and the other end is fixedly connected to the tail shell 3; The connecting terminal of the connector 1 is electrically connected to the cable wire 7 passing through the wire hole of the tail shell through the wire in the inner cavity of the tail cover; two piezoresistors 4 (5) are ...

Embodiment 2

[0035] On the basis of Example 1, in this embodiment, the number of heat-shrinkable tubes is 2, and the two ends of one heat-shrinkable tube are respectively wrapped on the outer circumference of the tail cover and the tail shell, and the two ends of the other heat-shrinkable tube are respectively wrapped on the tail housing and cable perimeter.

Embodiment 3

[0037] On the basis of embodiment 1, refer to Figure 1 to Figure 6 , In the present embodiment, the outer tail 3 is in the shape of a truncated cone, and one end with a larger cross-sectional diameter is fixedly connected to the end of the tail cover 2.

[0038] A ring groove 33 is provided in the middle of the tail shell 3; the heat shrinkable tube 8 includes two heat shrinkable tubes with different diameters, and one end of the heat shrinkable tube with a larger diameter is shrunk into the ring groove 33, and the other end wraps the tail cover 2 Facing one end of the connector, one end of the heat-shrinkable tube with a smaller diameter is shrunk and embedded in the ring groove 33 , and the other end wraps the cable 9 . Since the diameter of the connector end is larger and the diameter of the cable end is smaller, the present invention adopts segmental heat shrinkage to ensure the strength of the attachment at the end of the connector and is not easy to fall off, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com