Copper matte powder preparation and conveying equipment and factory building integrated configuration system

A technology of conveying equipment and configuration system, applied in the field of metallurgy, can solve the problems of unfavorable land-scarce smelter overall layout, complicated and complicated material conveying, large floor space, etc., achieving small floor space, low operating cost and saving land occupation area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

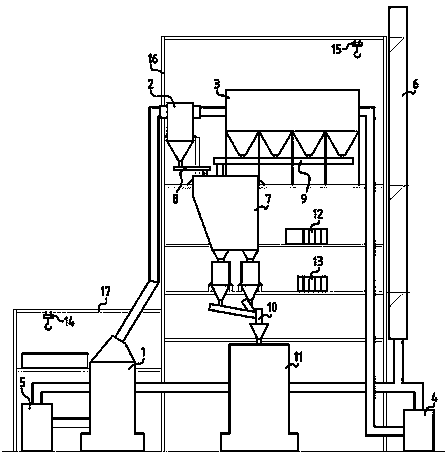

[0044] The present invention provides a matte powder preparation and conveying equipment and a plant integrated configuration system, the equipment includes a mill 1, a pre-dust collector 2, a dust collector 3, an exhaust fan 4, a hot blast stove 5, and an exhaust cylinder 6 , top silo 7, first conveyor 8 and second conveyor 9; said equipment is arranged in said factory building, and said factory building is made up of main span factory building 16 and attached span factory building 17, and said main span factory building 16 comprises Five floors, wherein the first floor is at the lowest; the attached span factory building 17 includes two floors and is located on the lateral side of the main span factory building 16, and the first floor is at the lowest.

[0045] The mill 1 is arranged on the first floor of the attached span factory building 17; the pre-dust collector 2 is connected to the mill 1, and is arranged at the outlet end of the mill 1, and is located at the side of th...

Embodiment 2

[0047]The present invention provides a matte powder preparation and conveying equipment and a plant integrated configuration system, the equipment includes a mill 1, a pre-dust collector 2, a dust collector 3, an exhaust fan 4, a hot blast stove 5, and an exhaust cylinder 6 , top silo 7, first conveyor 8, second conveyor 9 and quantitative feeding device 10; said equipment is arranged in said plant, said plant is made up of main span plant 16 and attached span plant 17, said The main span factory building 16 includes five floors, wherein the first floor is located at the lowest; the attached span factory building 17 includes two floors and is located on one lateral side of the main span factory building 16, wherein the first floor is located at the lowest.

[0048] The mill 1 is arranged on the first floor of the attached span factory building 17; the pre-dust collector 2 is connected to the mill 1, and is arranged at the outlet end of the mill 1, and is located at the side of ...

Embodiment 3

[0050] The present invention provides a matte powder preparation and conveying equipment and a plant integrated configuration system, the equipment includes a mill 1, a pre-dust collector 2, a dust collector 3, an exhaust fan 4, a hot blast stove 5, and an exhaust cylinder 6 , the top feed bin 7, the first conveyor 8, the second conveyor 9, the quantitative feeding device 10 and the metallurgical furnace 11; the equipment is arranged in the workshop, and the workshop consists of a main span workshop 16 and an attached span workshop 17 Composition, the main span factory building 16 includes five floors, wherein the first floor is located at the lowest; the attached span factory building 17 includes two floors and is located on the lateral side of the main span factory building 16, wherein the first floor is located at the lowest.

[0051] The mill 1 is arranged on the first floor of the attached span factory building 17; the pre-dust collector 2 is connected to the mill 1, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com