Manufacturing process of crease-resistant fabric

A manufacturing process and technology for anti-wrinkle fabrics, applied in the processing of textile materials, textiles and papermaking, textile processing machine accessories, etc. Competitiveness, increased automation, the effect of liberating productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

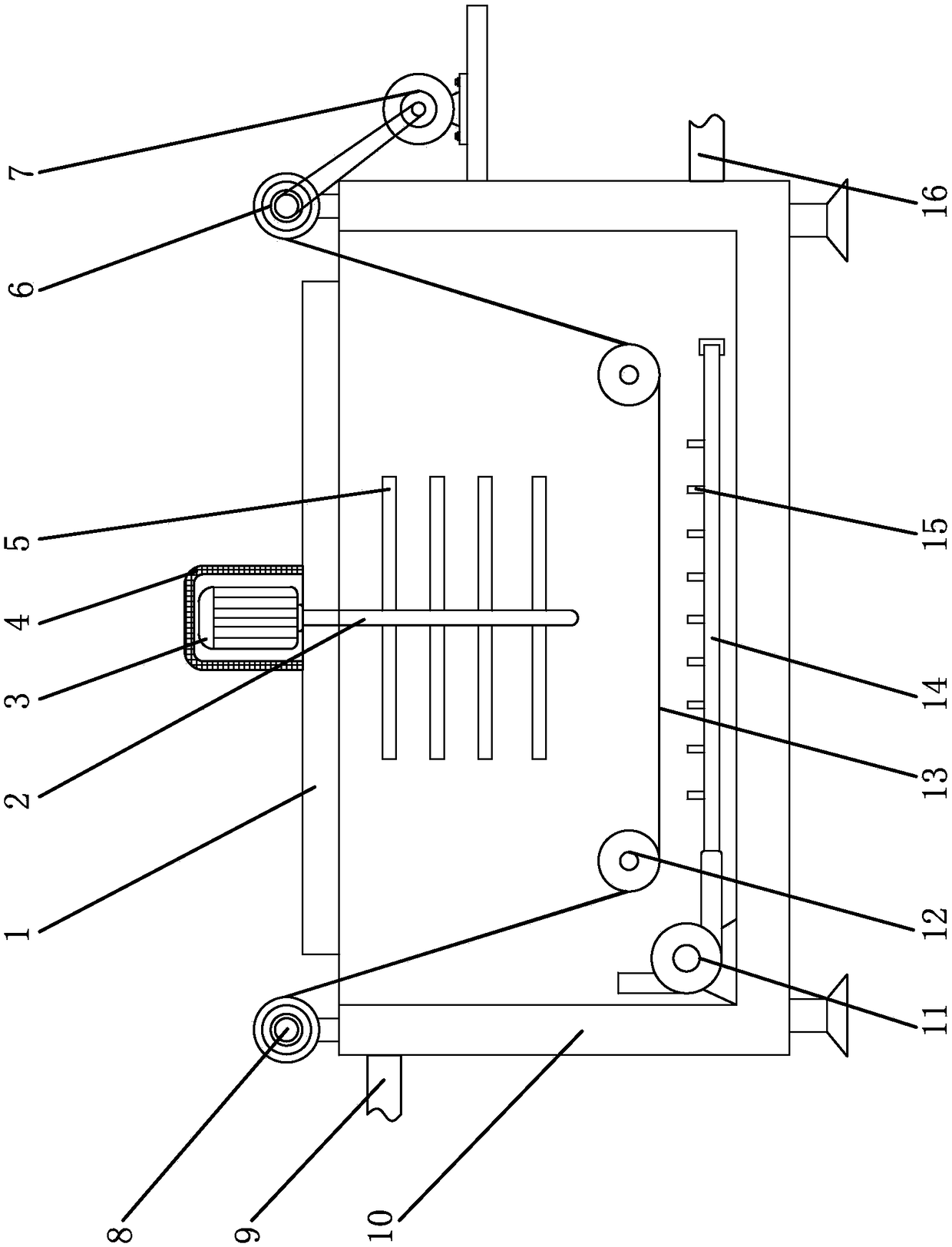

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

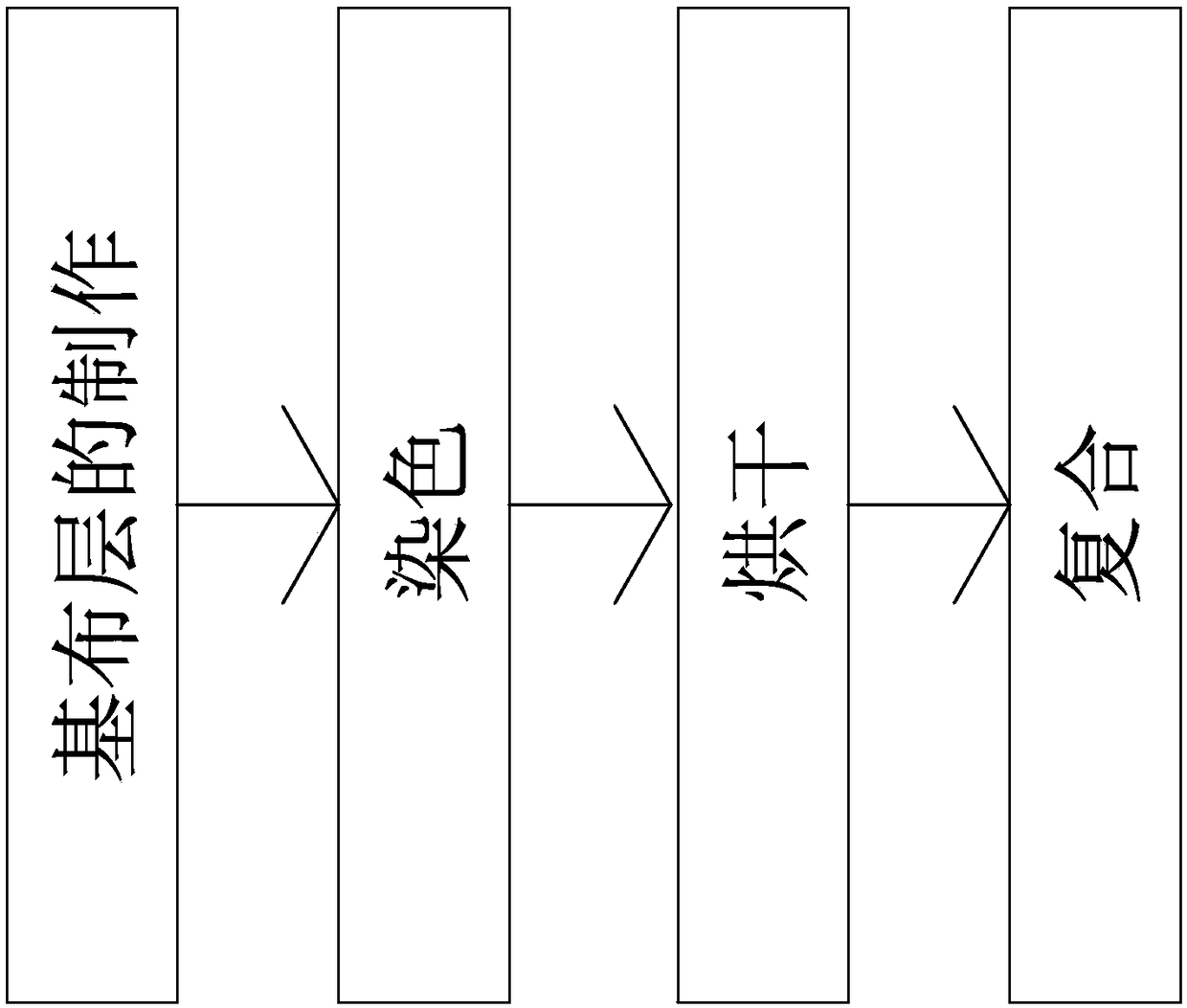

[0027] Such as Figure 1-4 Shown, a kind of manufacturing process of anti-wrinkle fabric, this manufacturing process comprises the following steps:

[0028] a, the making of base cloth layer 20: polyester and fiber are woven into base cloth layer 20 by weaving machine;

[0029] b, dyeing, dyeing the woven base cloth layer 20 through a dyeing vat for textile fabric processing;

[0030] c, drying, using a dryer to dry the base cloth layer 20 after step b treatment;

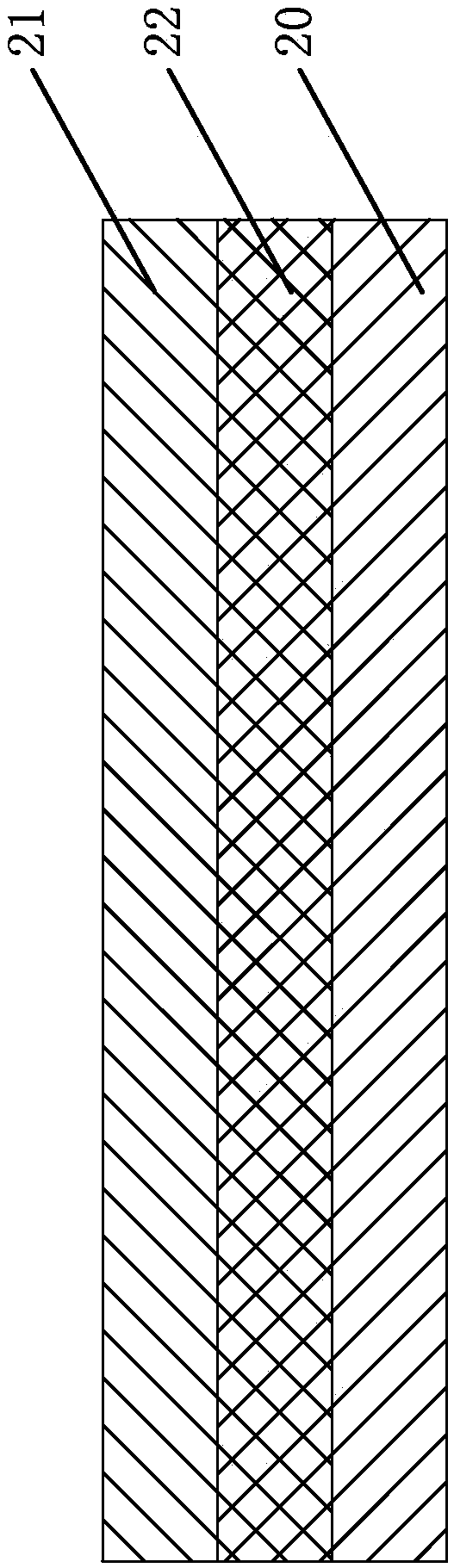

[0031] d. Composite, select the existing polycarbonate PU film on the market as the outer layer 21, and paste some polyurethane anti-wrinkle strips 22 between the outer layer 21 and the base cloth layer 20.

[0032] The manufacturing process of the anti-wrink...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com