Mixed ignition device for shock wave dust cleaning system

An ignition device and ash cleaning technology, which is applied in the direction of ignition by electric spark, combustion ignition, and removal of solid residues, etc., can solve the problems of complex configuration structure, high operation failure rate, and low operation efficiency, and achieve low operation and maintenance costs , low failure rate and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

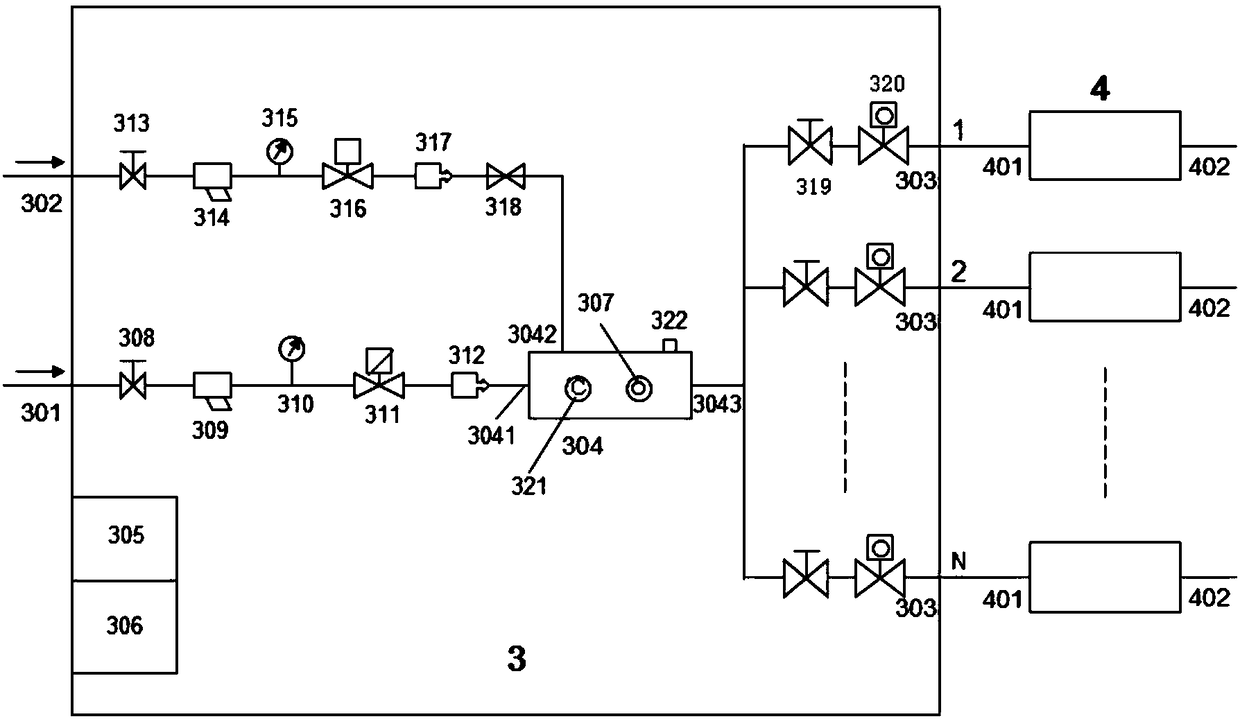

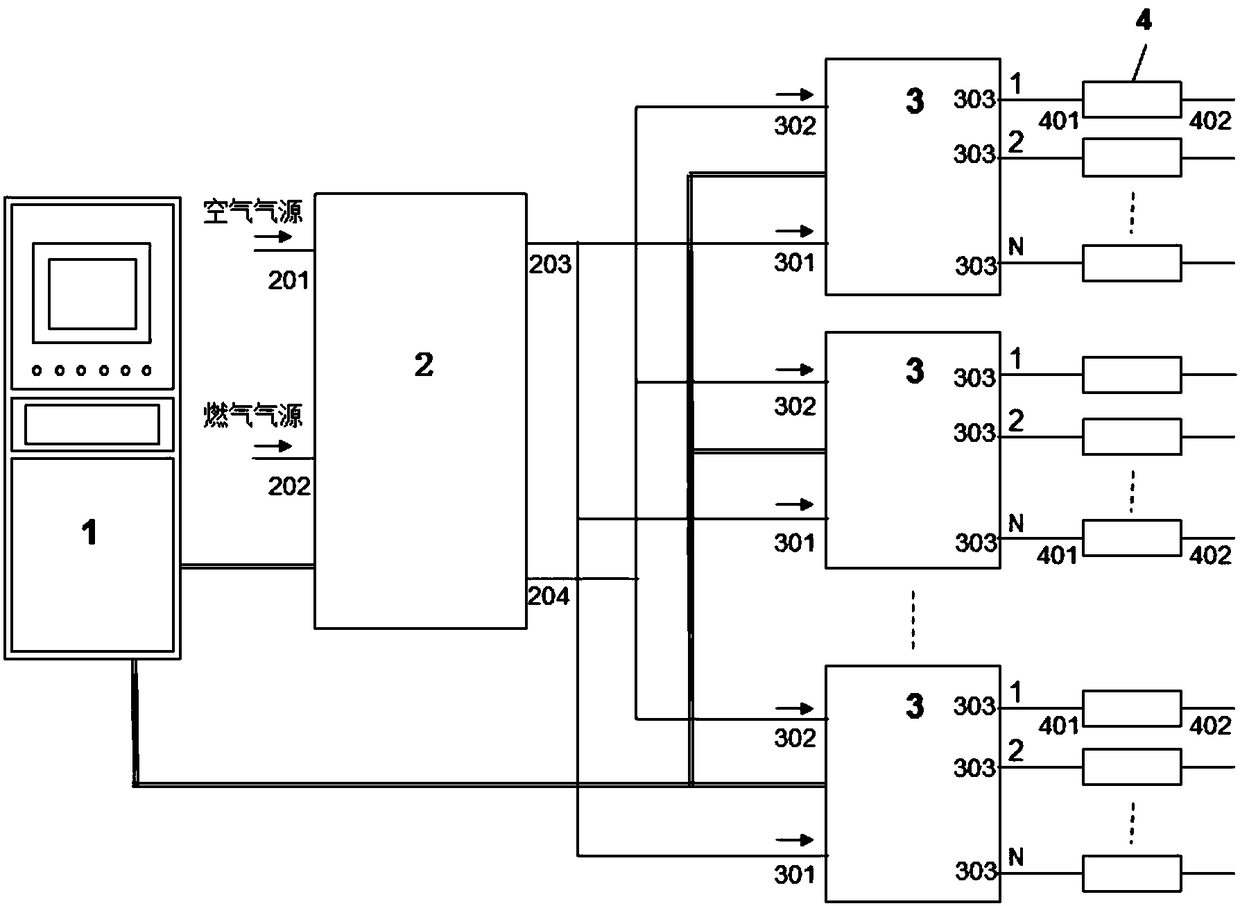

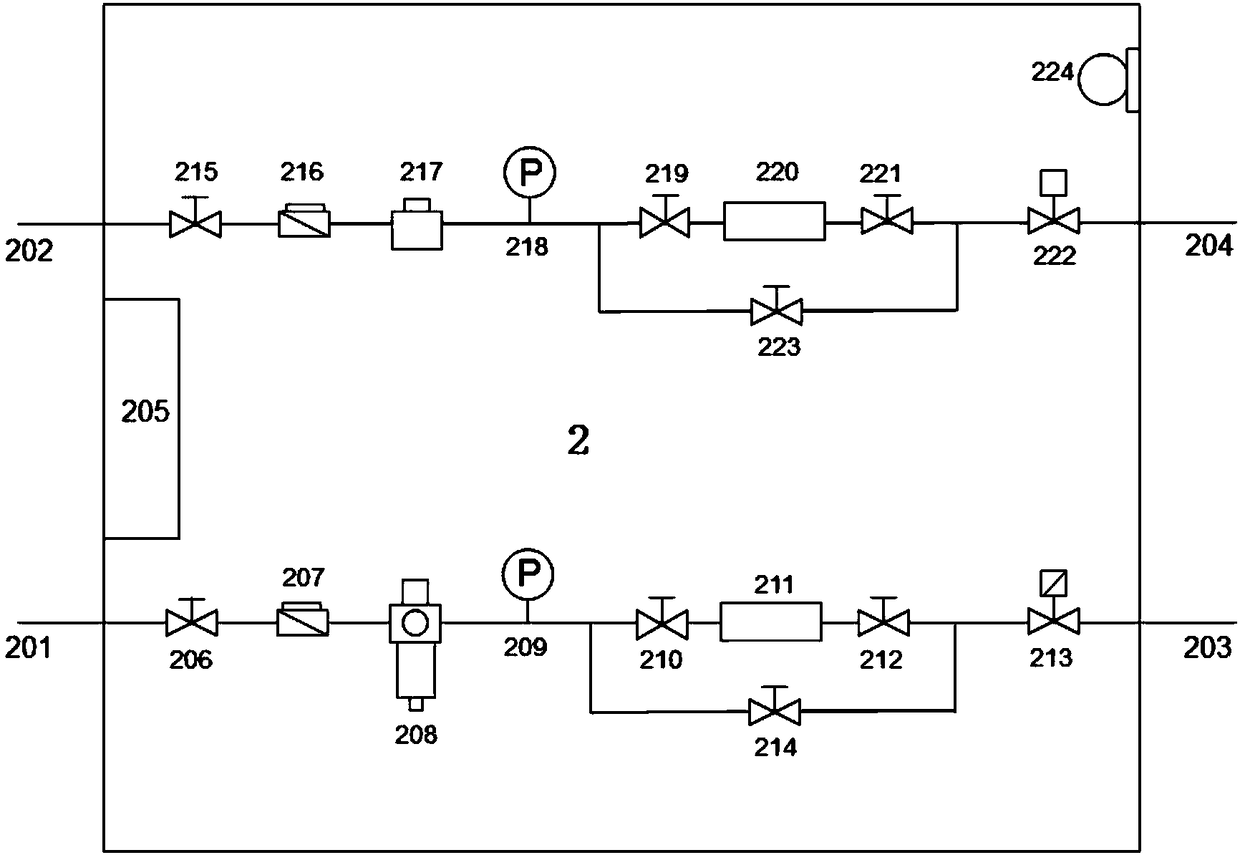

[0037] Such as figure 1 and figure 2 As shown, the embodiment of the present invention provides a shock wave dust removal system, including a dust removal control device 1 , an air source supply device 2 , and several sets of shock wave generators 4 . The gas supply device 2 includes a first gas pipeline, a first air pipeline and a first terminal box 205; the gas inlet 202 of the first gas pipeline is connected to the gas source, and the first air pipeline The air inlet 201 of the road is connected to the air source; the dust removal control device 1 is connected to the first terminal box 205 through a control cable; the hybrid ignition device 3 includes a second gas pipeline, a second air pipeline , a mixing tank 304, n mixed gas pipelines, a second terminal box 305, an ignition control box 306 and an ignition head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com