Low-internal-resistance supercapacitor core and preparation technology

A supercapacitor and preparation process technology, applied in the fields of hybrid capacitor current collectors, hybrid/electric double layer capacitor manufacturing, electrolytic capacitors, etc., can solve the problems of high internal resistance and complex process, achieve lower surface temperature and high product qualification rate , the effect of reducing the internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Take 90kg of capacitor carbon, 7kg of conductive carbon black and 3kg of PTFE and mix them evenly. After multiple times of kneading, the above-mentioned mixing and pressing are made into a carbon film; then the carbon film is pressed on the aluminum foil current collector coated with conductive glue in advance, and the entire electrode sheet The width is 200mm, and a blank area of 10mm is left on the edge of the aluminum foil (non-capacitive carbon, conductive carbon black and PTFE substances);

[0036] (2) Put the completed electrode sheet into a roller press and press it under a pressure of 50MPa to obtain a pressed electrode sheet with an electrode density of 0.7g / cm 3 ;

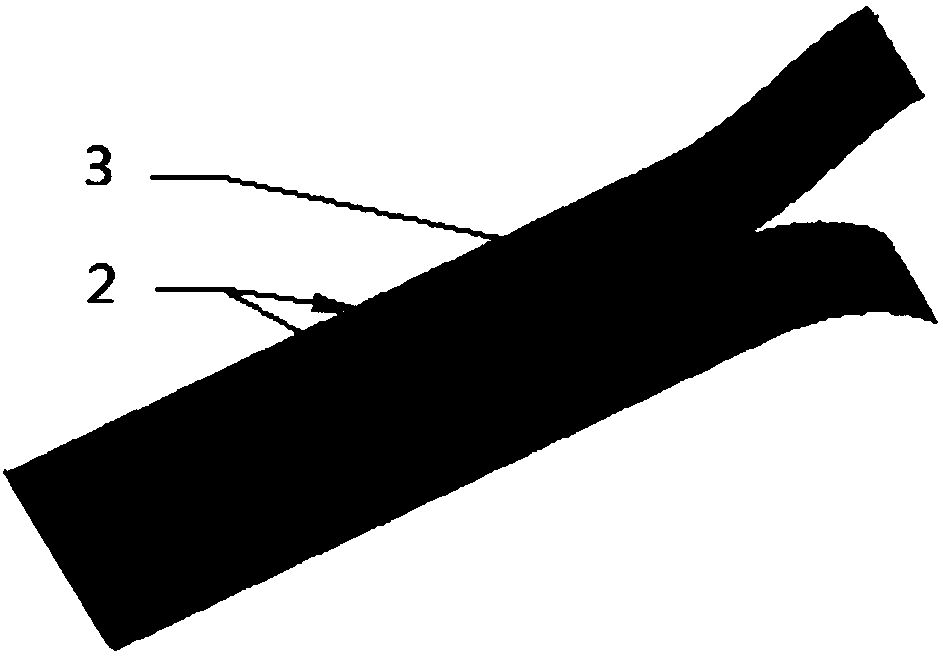

[0037] (3) Cut the pressed electrode piece longitudinally from the middle, divide it into two parts, and use it as two pole pieces of a supercapacitor (such as figure 1 );

[0038] (4) cutting the electrode sheet into a length of 500 mm to obtain an electrode sheet for the winding process; ...

Embodiment 2

[0044] (1) Take 90kg of capacitor carbon, 7kg of conductive carbon black and 3kg of PTFE and mix them evenly. After multiple times of kneading, the above-mentioned mixing and pressing are made into a carbon film; then the carbon film is pressed on the aluminum foil current collector coated with conductive glue in advance, and the entire electrode sheet The width is 150mm, and a blank area of 15mm is left on the edge of the aluminum foil (non-capacitor carbon, conductive carbon black and PTFE substances);

[0045] (2) Put the completed electrode sheet into a roller press and press it under a pressure of 30MPa to obtain a pressed electrode sheet with an electrode density of 0.5g / cm 3 ;

[0046] (3) Cut the pressed electrode piece longitudinally from the middle, divide it into two parts, and use it as two pole pieces of a supercapacitor (such as figure 1 );

[0047] (4) cutting the electrode sheet into a length of 1000 mm to obtain an electrode sheet for the winding process; ...

Embodiment 3

[0053] (1) Take 90kg of capacitor carbon, 7kg of conductive carbon black and 3kg of PTFE and mix them evenly. After multiple times of kneading, the above-mentioned mixing and pressing are made into a carbon film; then the carbon film is pressed on the aluminum foil current collector coated with conductive glue in advance, and the entire electrode sheet The width is 300mm, and a blank area of 23mm is left on the edge of the aluminum foil (non-capacitive carbon, conductive carbon black and PTFE substances);

[0054] (2) Put the completed electrode sheet into a roller press and press it under a pressure of 50MPa to obtain a pressed electrode sheet with an electrode density of 0.6g / cm 3 ;

[0055] (3) Cut the pressed electrode piece longitudinally from the middle, divide it into two parts, and use it as two pole pieces of a supercapacitor (such as figure 1 );

[0056] (4) cutting the electrode sheet into a length of 2000mm to obtain an electrode sheet for the winding process; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com