Lithium ion battery anode material and preparation method thereof

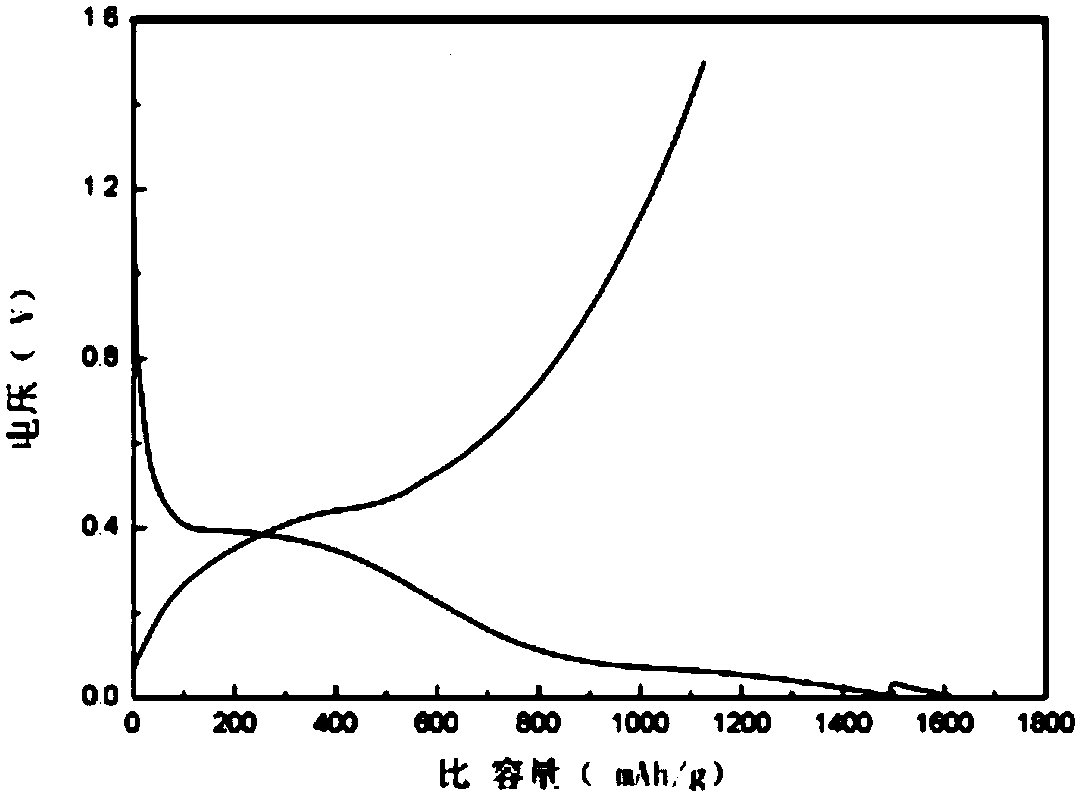

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low compaction density, easy crushing, etc., achieve simple preparation method, improve electrical conductivity and cycle stability, The effect of good cycle stability and rate capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

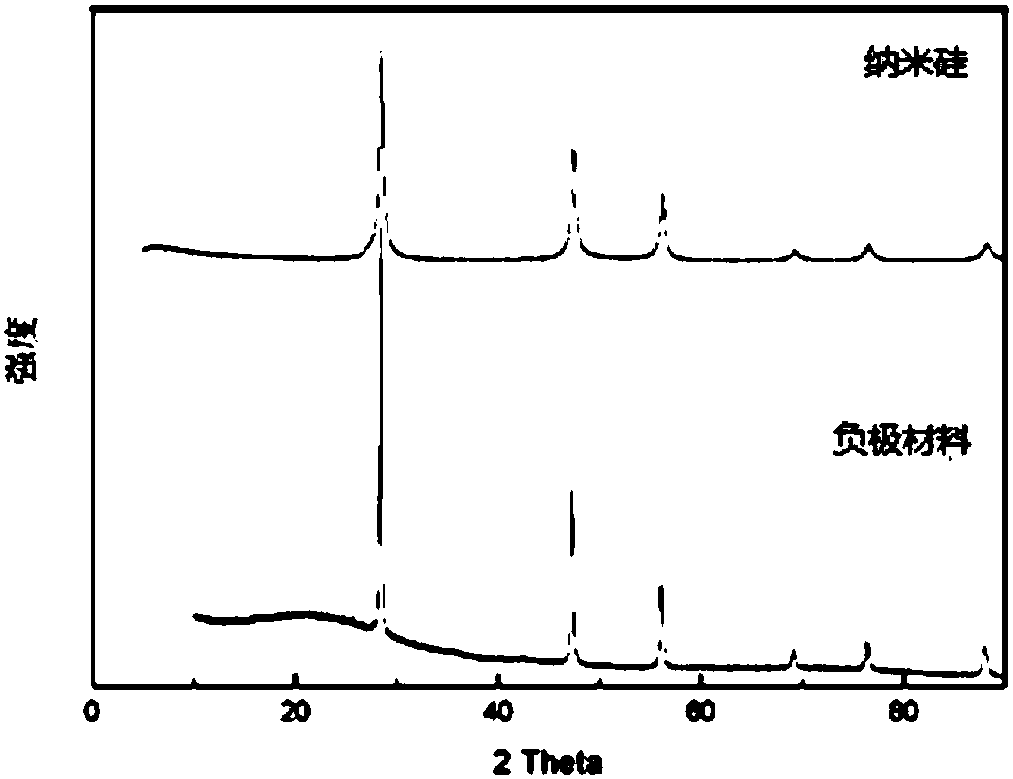

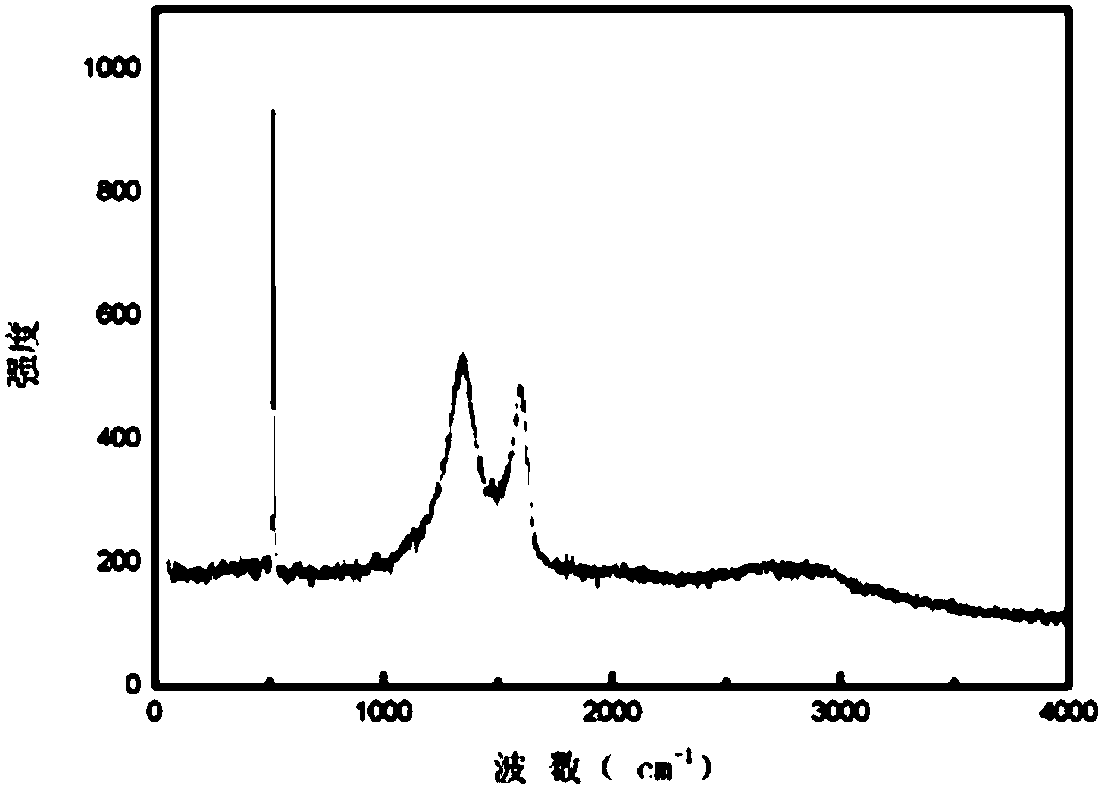

[0032] A negative electrode material for a lithium ion battery. The negative electrode material includes the following raw materials by weight percentage: 40% of organic silicon resin, 40% of nano-silicon, and 20% of carbon source.

[0033] The preparation method of described lithium ion battery negative electrode material, comprises the steps:

[0034] S1. Mix the silicone resin, nano-silicon, and carbon source evenly to obtain solution A;

[0035] S2, add acidic solution to solution A, stir to obtain solution B;

[0036] S3. Add an alkaline solution to solution B, stir to obtain solution C, and evaporate solution C to dryness under oil bath conditions to obtain a Si / C / SiOC precursor;

[0037] S4, the Si / C / SiOC precursor is sintered.

Embodiment 2

[0039] A negative electrode material for a lithium ion battery. The negative electrode material includes the following raw materials by weight percentage: 85% of organic silicon resin, 10% of nano-silicon, and 5% of carbon source.

[0040] The preparation method of described lithium ion battery negative electrode material, comprises the steps:

[0041] S1. Mix the silicone resin, nano-silicon, and carbon source evenly to obtain solution A;

[0042] S2, add acidic solution to solution A, stir to obtain solution B;

[0043] S3. Add an alkaline solution to solution B, stir to obtain solution C, and evaporate solution C to dryness under oil bath conditions to obtain a Si / C / SiOC precursor;

[0044] S4, the Si / C / SiOC precursor is sintered.

Embodiment 3

[0046] A lithium ion battery negative electrode material, said negative electrode material comprises the following raw materials by weight: organic silicon resin 12.5g, nano-silicon 5g, carbon source 1g;

[0047] Wherein, the silicone resin is methyltriethoxysilane;

[0048] The nano-silicon is a silicon nanofiber;

[0049] The carbon source is carbon nanofibers.

[0050] The preparation method of described lithium ion battery negative electrode material, comprises the steps:

[0051] S1. Mix the silicone resin, nano-silicon, and carbon source evenly to obtain solution A;

[0052] S2, add acidic solution to solution A, obtain solution B after stirring for 1 h;

[0053] S3, adding an alkaline solution to solution B, stirring for 1 hour to obtain solution C, and evaporating solution C to dryness in an oil bath to obtain a Si / C / SiOC precursor;

[0054] S4, sintering the Si / C / SiOC precursor;

[0055] Wherein, in S2, add acidic solution to solution A to make the pH value of so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com