Lithium-ion battery internally provided with heat dissipation structure

A technology of lithium ion battery and heat dissipation structure, applied in the field of lithium ion battery, can solve the problems of increasing the overall production cost, occupying limited space of the car, impairing the performance and life of the battery, etc., achieving great practical significance in production, preventing uneven temperature, guaranteeing Use safe effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

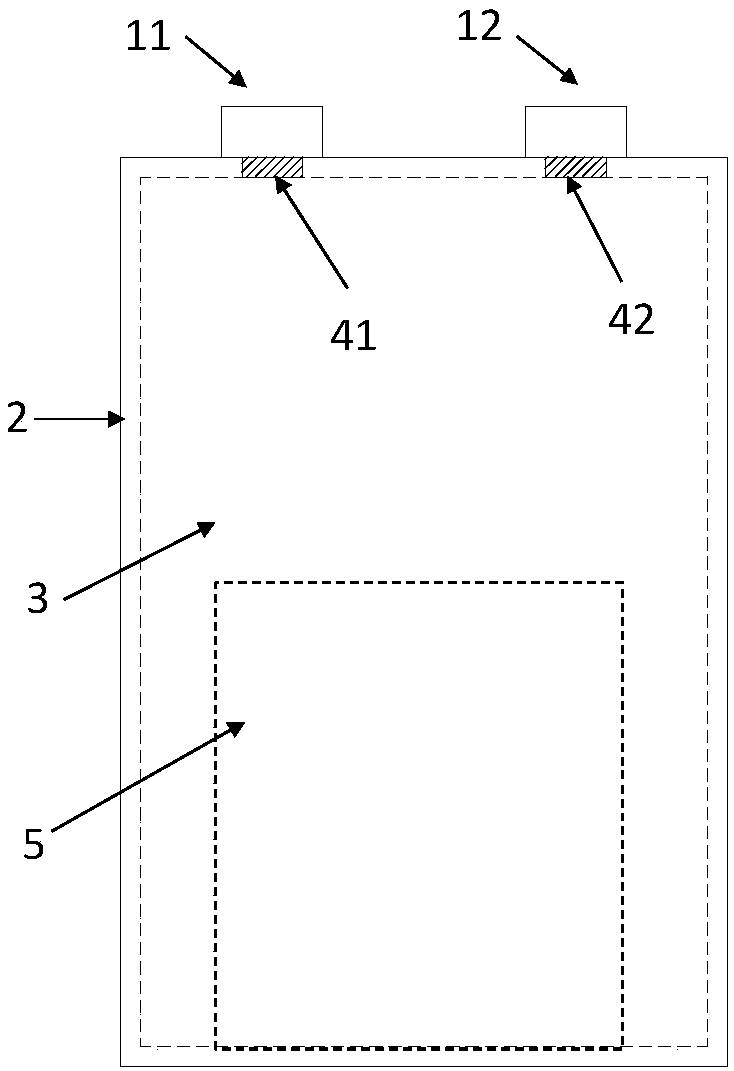

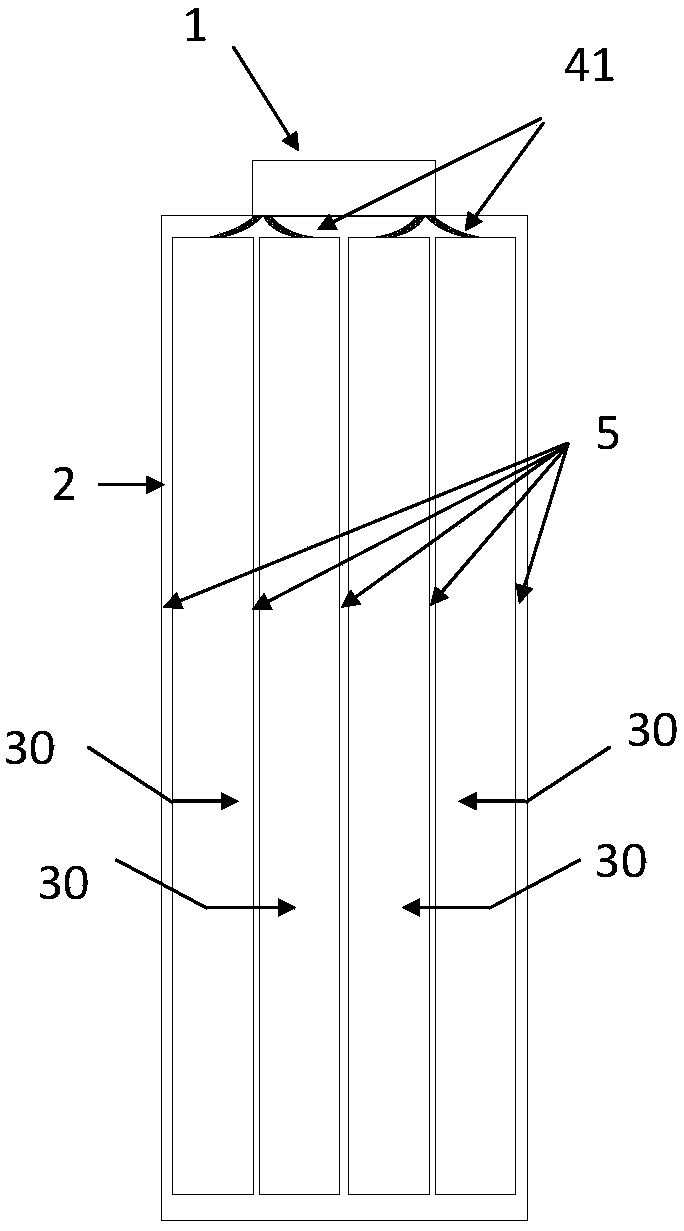

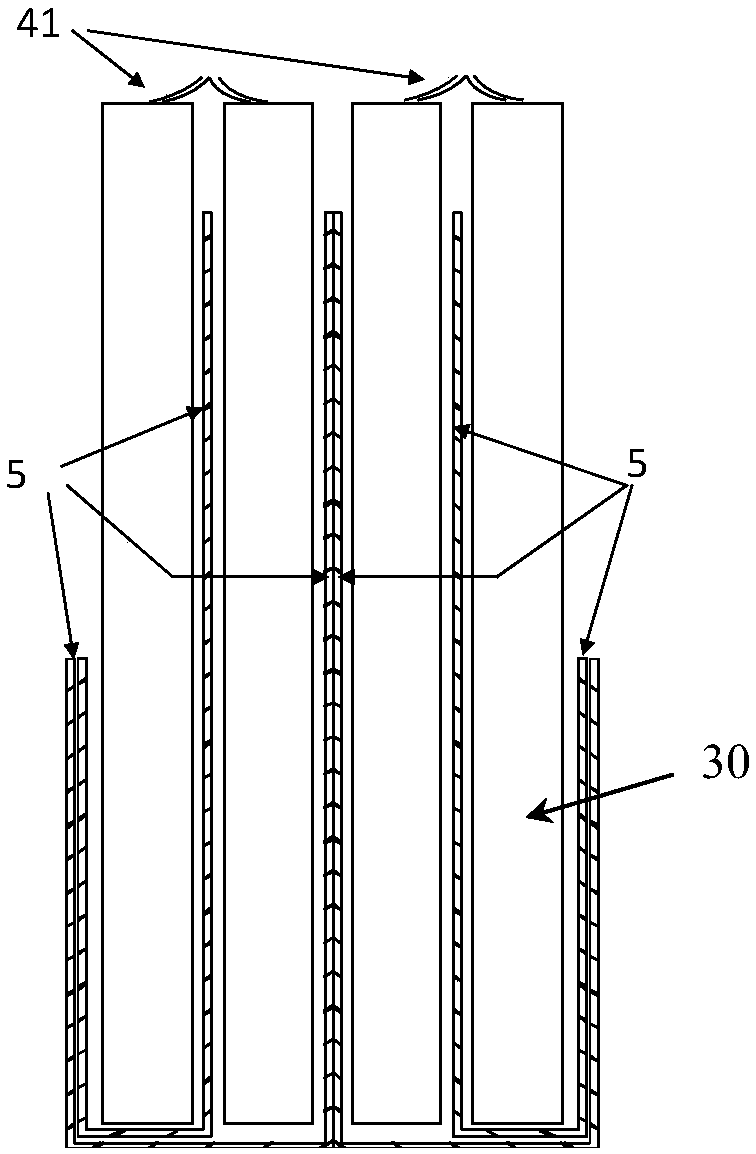

[0029] see Figure 1 to Figure 4 , the present invention provides a lithium-ion battery with a built-in heat dissipation structure, which can quickly and effectively dissipate the heat inside the battery by setting heat dissipation fins inside the battery, and dissipate the heat to the outside of the battery, effectively preventing Performance and safety problems caused by uneven internal temperature and overheating of the battery.

[0030] The lithium-ion battery with built-in heat dissipation structure provided by the present invention specifically includes a battery case 2, and the top, left and right ends of the battery case 2 have positive poles 11 and negative poles 12 respectively;

[0031] The battery casing 2 has a battery core cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com