Automatic meat cutting method

An automatic threading and automatic technology, which is applied in the fields of climate change adaptation, food shaping, food science, etc., can solve the problems of insecurity and low efficiency of manual threading, and achieve high safety, improved meat tenderness, and tangy aroma Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Example 1: Select 100kg of fresh boneless pork, after removing the surface fascia, soak it in alkaline brine with a salt content of 5% and an alkali content of 0.3% at 15°C for 20 minutes, then rinse with clean water and drain; Cut the drained fresh meat into slices with a thickness of 1cm; cut the meat slices with salt 1kg, pepper oil 0.6kg, starch 1.5kg, soy sauce 3kg, vinegar 0.3kg, honey 1kg, pepper 0.6kg, chili powder 1kg, Mix 1 kg of grass fruit powder, 0.5 kg of star anise powder, 1 kg of fennel powder, and 0.5 kg of wood ginger oil, and marinate for 40 minutes; then transfer the marinated meat into a vibrating sieve with a speed of 800 rpm for sieving. Sieve off the ingredients on the surface of the meat, and take the meat for later use; in order to make the meat tough and easy to sign, the sieved meat can be quick-frozen, and stop the quick-freezing in time when the surface of the meat has a slight hard texture and does not freeze. ; Put the quick-frozen meat co...

Embodiment 2

[0055] Example 2: The difference between this example and example 1 is only that: the meat is boneless beef, soaked in saline-alkali water with a salt content of 4% and an alkali content of 0.4% at 20°C for 30 minutes, Dried fresh meat is cut into slices with a thickness of 2 cm; 100 kg of fresh beef slices, 1.1 kg of salt, 0.5 kg of pepper oil, 1.8 kg of starch, 2.5 kg of soy sauce, 0.4 kg of vinegar, 1.5 kg of honey, 0.5 kg of pepper, Chili powder 1.5kg, grass fruit powder 0.8kg, star anise powder 0.8kg, fennel powder 0.8kg, wood ginger seed oil 0.8kg mix and marinate for 60min; then transfer the meat into a vibrating sieve with a rotation speed of 900 rpm for sieving Minute.

Embodiment 3

[0056] Example 3: The difference between this example and Example 1 is only that: the meat is boneless lamb, which is immersed in saline-alkali water with a salt content of 3% and an alkali content of 0.4% at 25°C for 25 minutes. Dried fresh meat is cut into slices with a thickness of 3 cm; 100 kg of fresh lamb slices, 1.2 kg of salt, 0.4 kg of pepper oil, 2 kg of starch, 2 kg of soy sauce, 0.5 kg of vinegar, 2 kg of honey, 0.4 kg of pepper, and 2 kg of chili powder , 0.5 kg of grass fruit powder, 1 kg of star anise powder, 0.5 kg of fennel powder, and kg of wood ginger oil, mixed and marinated for 60 minutes; then the meat is transferred into a vibrating sieve with a rotation speed of 1000 rpm for screening.

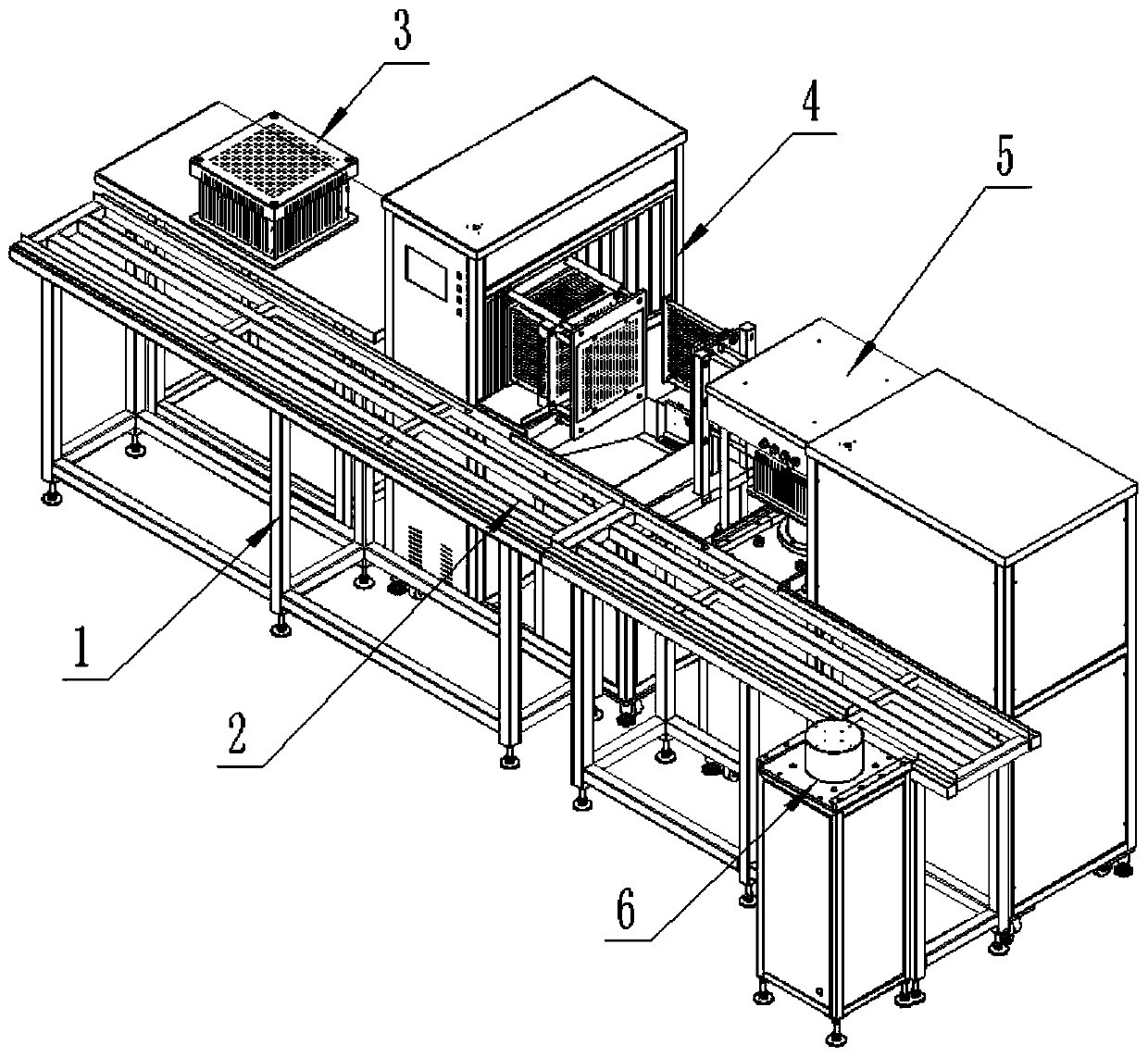

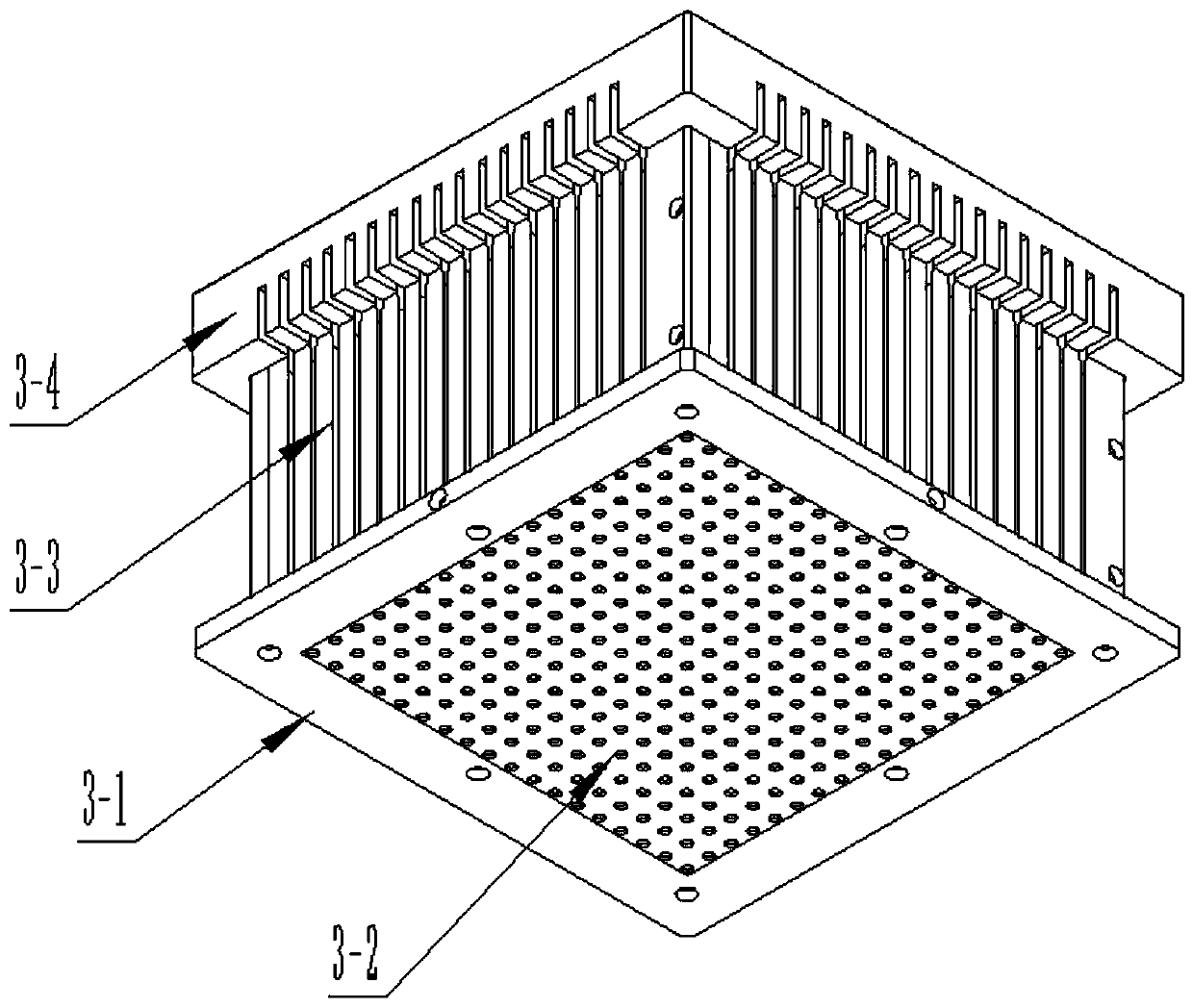

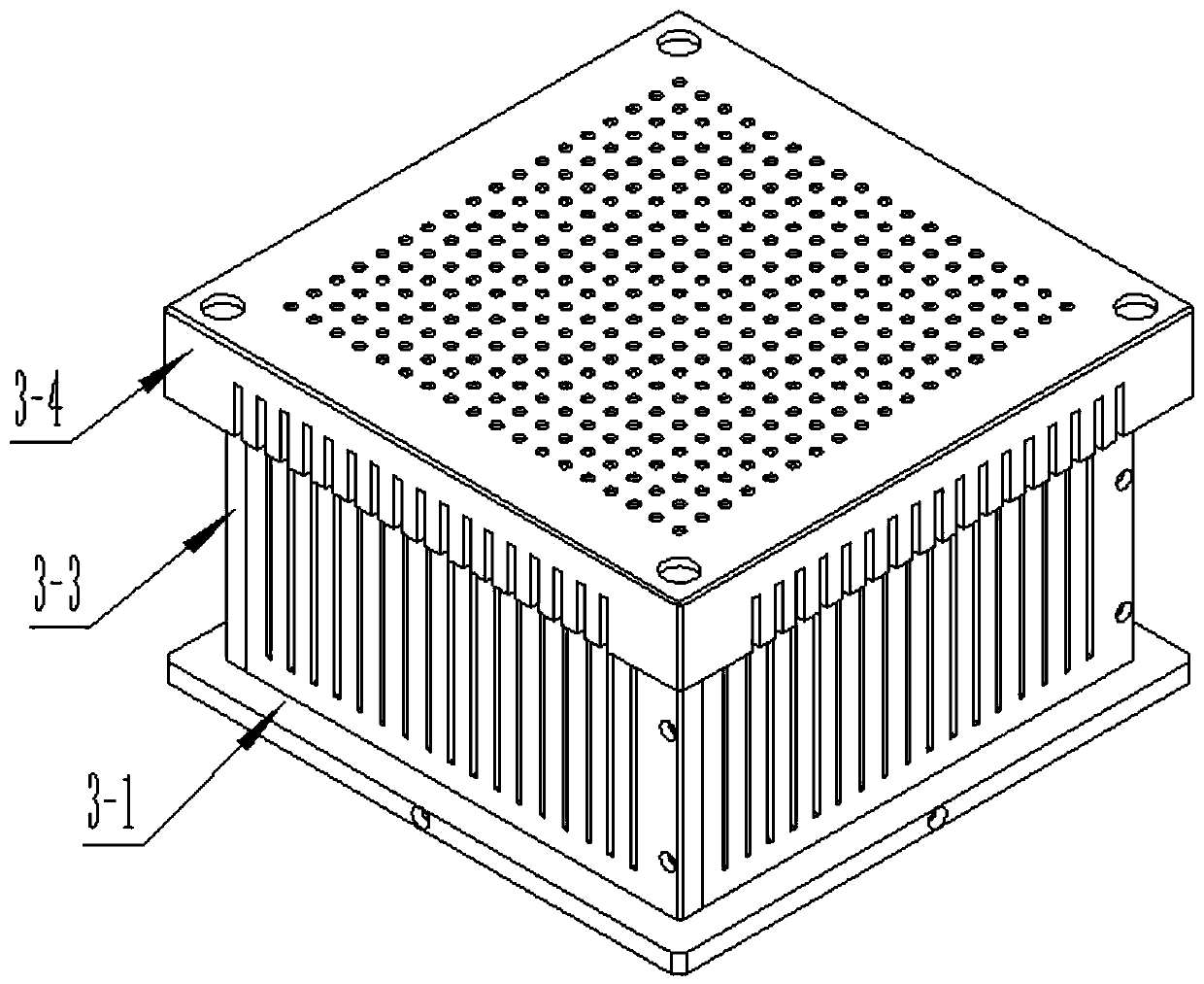

[0057] The automatic meat cutting and stringing machine used in the above embodiment consists of a chute 2 arranged on the frame 1, a meat skewer device 3, an automatic stringing device 4, an automatic skewer cutting device 5, and a meat skew The output device 6 is compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com