Integrated type centralized fountain solution automatically-proportioning device

An automatic proportioning and dampening solution technology, which is applied in transportation and packaging, mixer accessories, dissolution, etc., can solve the problems of excessive ink emulsification, water tank dampening solution is easy to dirty, and the dot expansion of graphic parts, etc., to achieve low cost , simple structure, and the effect of improving printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

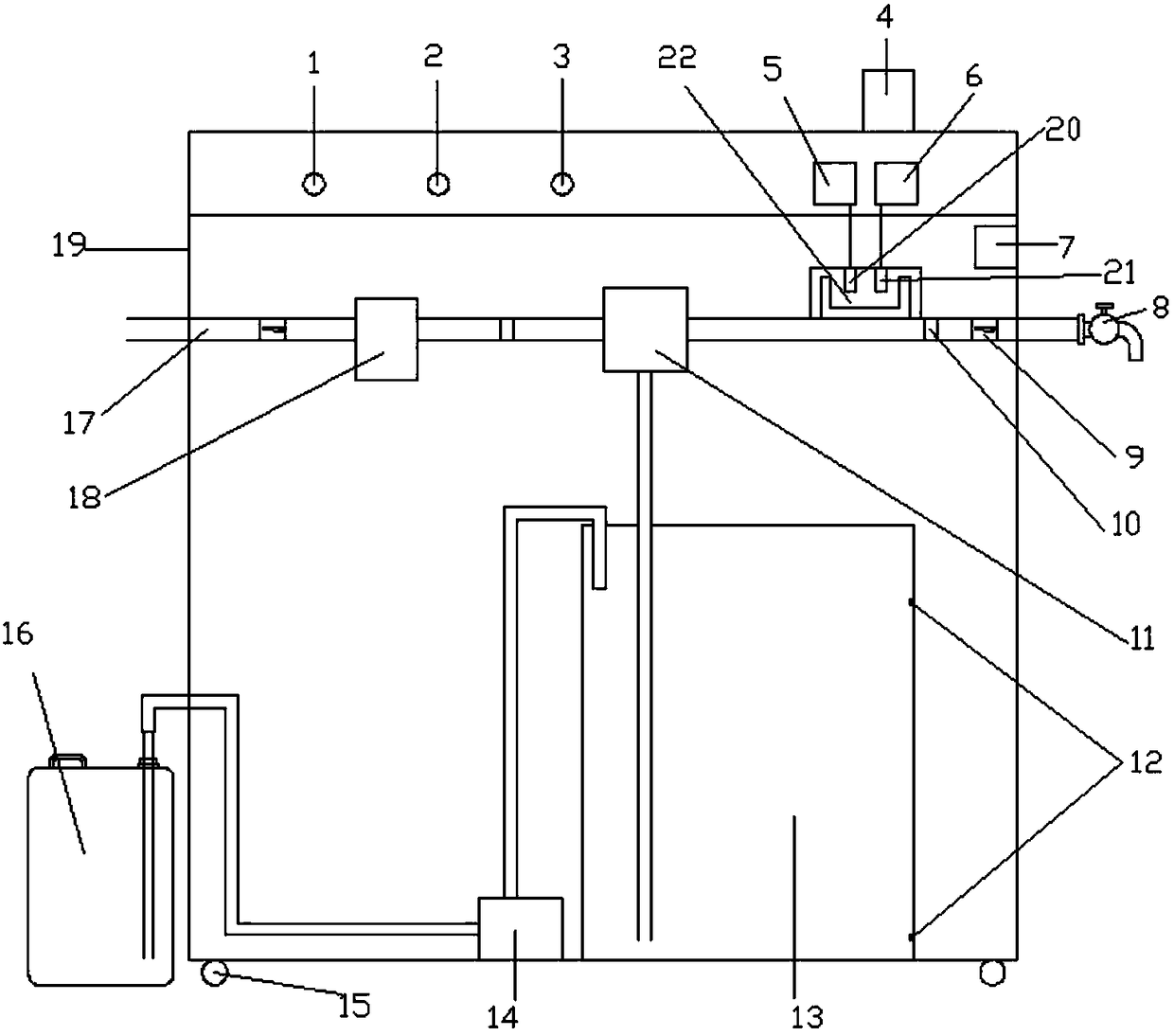

[0013] Embodiment: An integrated centralized dampening solution automatic proportioning device, including a power switch 1, a liquid addition switch 2, an instrument switch 3, an alarm light 4, a pH meter 5, a conductivity meter 6, an alarm controller 7, and a liquid distribution outlet Switch 8, water valve 9, check valve 10, proportioning pump 11, liquid level sensor 12, liquid storage tank 13, liquid filling pump 14, universal wheel 15, raw liquid tank 16, water pipe 17, water filter 18, housing 19. PH value sensor 20, conductance value sensor 21, proportioning liquid detection device 22, the power switch 1 is located on the left side of the front of the casing 19, and the right side of the power switch 1 is sequentially distributed with a liquid filling switch 2, an instrument switch 3, and a pH Meter 5 and conductivity meter 6, the alarm light 4 is located on the top right side of the shell 19, the alarm light 4 is connected to the alarm controller 7, the water pipe 17 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com