Small portable finish machining grinding device

A grinding device, portable technology, applied in the direction of grinding devices, grinding drive devices, grinding machine tools, etc., can solve the problems of complex structure, inconvenient maintenance, large volume, etc., and achieve high processing accuracy and surface roughness, which is easy to carry, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

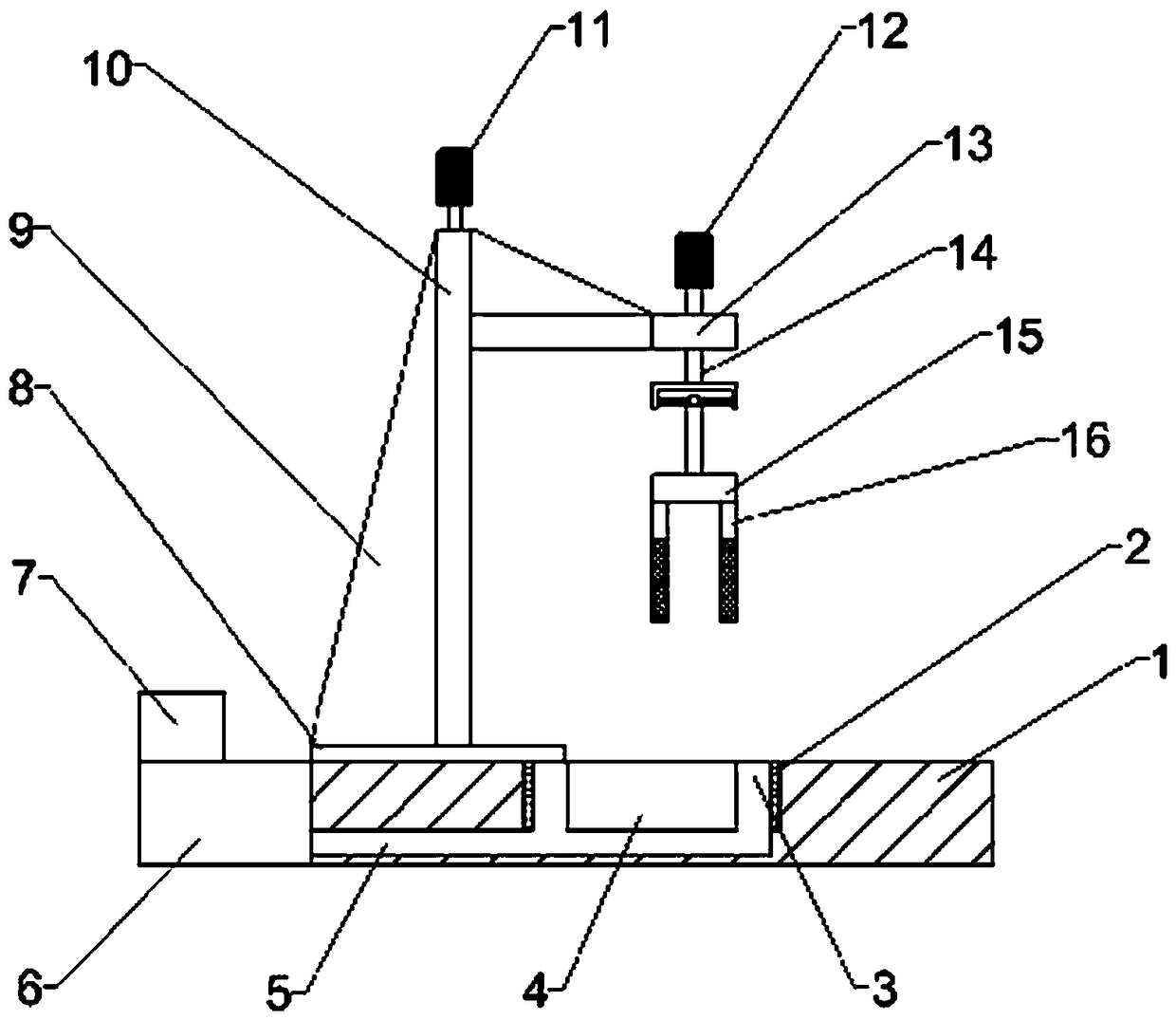

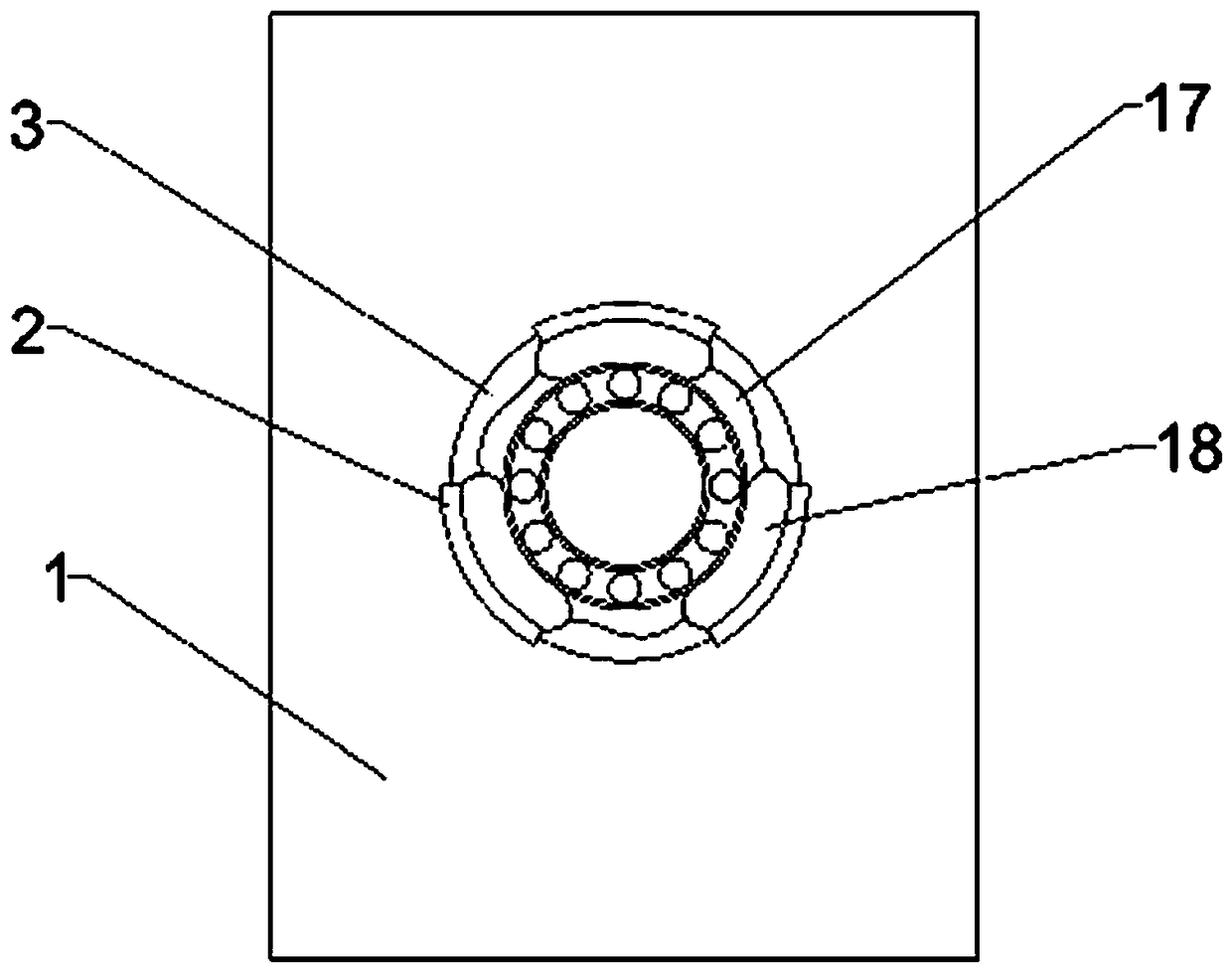

[0022] A small portable finishing grinding device, including a fixed seat 1, a clamping sleeve 2, a shrinkable capsule body 3, a fixed cavity 4, a hydraulic tube 5, a hydraulic console 6, a pressure gauge 7, a fixed plate 8, a support plate 9, a straight line Slide table 10, slide table motor 11, rotating motor 12, support table 13, universal joint coupling 14, turntable 15, pneumatic grinding rod 16, bag body 17, bag body fixing block 18, it is characterized in that: fixed seat 1 There is a clamping sleeve 2 in the middle, and the bottom is paved with shrinkable capsules 3 to form a fixed cavity 4. A fixed plate 8 is fixed on the fixed seat 1. The support plate 9 fixes the linear slide 10 on the fixed plate 8. The linear slide 10 is provided with There is a support platform 13, and the rotary motor 12 above the support platform 13 is connected with the turntable 15 through the universal joint coupling 14 below, and the turntable 15 is provided with two pneumatic grinding rods ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap