Automatic tray type fruit and vegetable packaging device

An automatic packaging and tray-type technology, which is applied in the field of agricultural machinery, can solve the problems of high packaging machinery prices and low automation, and achieve the effects of reducing labor costs, ensuring effects and safety, and increasing mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

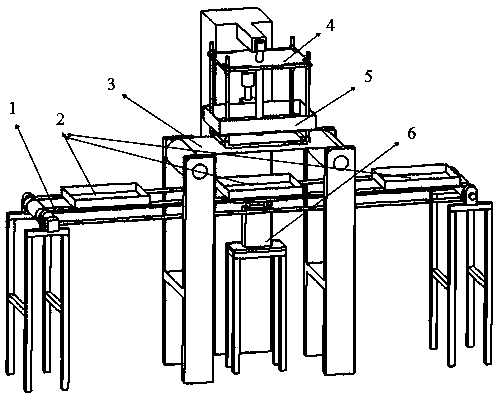

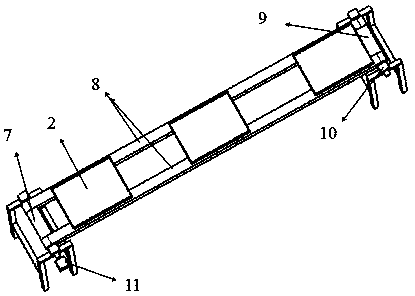

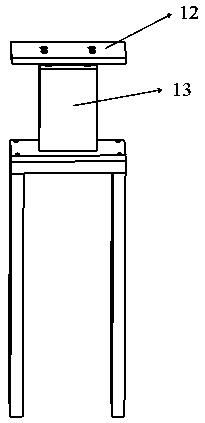

[0022] see figure 1 , a tray-type automatic packaging device for fruits and vegetables, composed of a conveyor belt mechanism 1, a tray 2, a film pulling mechanism 3, a wrapping mechanism 4, a film cutting mechanism 5, and a tray pushing mechanism 6, and is characterized in that the width of the tray pushing mechanism 6 is less than two The gap between the two conveyor belts, so that the tray pushing mechanism 6 can move freely between the two conveyor belts, and does not affect the movement of the conveyor belt mechanism 1; the length of the film pulled by the film pulling mechanism 3 is greater than the length of the tray 2, and the width of the film is greater than that of the tray 2; the height of the film is higher than the height of the fruits and vegetables contained in the tray 2; the initial position heights of the film cutting mechanism 5 and the wrapping mechanism 4 are all greater than the height of the film; the length and width of the film cutting mechanism 5 are ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap