Cyanate ester modified resin with low Dk/Df value as well as preparation method thereof

A technology of cyanate resin and modified resin, which is applied in chemical instruments and methods, glass/slag layered products, layered products, etc., can solve the problem of high Dk/Df, and achieve improved dielectric properties and heat resistance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

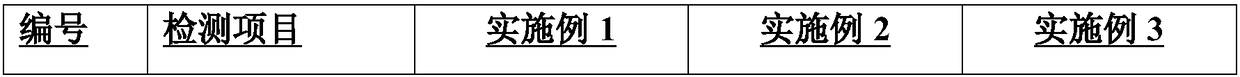

Embodiment 1

[0029] A kind of preparation method of the cyanate ester modified resin of low Dk / Df value, comprises the following steps:

[0030] 1) 42% novolac epoxy resin by weight ratio; 42% P-containing phenolic resin; 10% cyanate resin is made into a solution, and mixed to obtain a mixed solution;

[0031] 2) Add 6% by weight diluent acetone to the mixed liquid in step 1) to adjust to a suitable solid content of 70%. (Add propylene glycol methyl ether to make glue; glass fiber cloth is dipped in glue and dried; pressed with copper foil to make copper clad laminate) At this time, the Dk / Df value of the solidified product of the cyanate modified resin is 4.1 / 0.011.

[0032] In addition, it is also possible to add 15% PTFE resin micropowder in the weight percentage to the cyanate ester modified resin solid obtained in step 2), stir evenly, (adding propylene glycol methyl ether is adjusted into a glue solution; glass fiber cloth is dipped in glue, baked Dry; pressed with copper foil to ...

Embodiment 2

[0034] A kind of preparation method of the cyanate ester modified resin of low Dk / Df value, comprises the following steps:

[0035] 1) 42% novolac epoxy resin by weight ratio; 42% P-containing phenolic resin; 10% cyanate resin is formulated into a solution, and mixed to obtain a mixed solution;

[0036] 2) Add 6% by weight diluent acetone to the mixed liquid in step 2) to adjust to a suitable solid content. (Add propylene glycol methyl ether to make glue; glass fiber cloth is dipped and dried; pressed with copper foil to make copper clad laminate) At this time, the Dk / Df value of the cyanate modified resin solid product is 4.1 / 0.011 .

[0037] In addition, it is also possible to add 20% PTFE resin micropowder by weight percentage to the cyanate ester modified resin solid obtained in step 2), stir evenly, (add propylene glycol methyl ether to adjust into glue; glass fiber cloth dipped in glue, baked Dry; pressed with copper foil to form a copper clad laminate) to obtain a pro...

Embodiment 3

[0039] A kind of preparation method of the cyanate ester modified resin of low Dk / Df value, comprises the following steps:

[0040] 1) 41% novolac epoxy resin by weight ratio; 41% P-containing phenolic resin; 12% cyanate resin is formulated into a solution, and mixed to obtain a mixed solution;

[0041] 2) Add 6% by weight diluent acetone to the mixed liquid in step 2) to adjust to a suitable solid content. (Add propylene glycol methyl ether to make glue; glass fiber cloth is dipped and dried; pressed with copper foil to make copper clad laminate) At this time, the Dk / Df value of the cyanate modified resin solid product is 4.0 / 0.011 .

[0042] In addition, it is also possible to add 15% PTFE resin micropowder in the weight percentage to the cyanate ester modified resin solid obtained in step 2), stir evenly, (adding propylene glycol methyl ether is adjusted into a glue solution; glass fiber cloth is dipped in glue, baked Dry; pressed with copper foil to form a copper clad la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com