Probiotics strain preparation and culture method thereof

A culture method and technology of probiotics, applied in the field of probiotics, can solve problems such as long production cycle, low production efficiency, and long activation time, and achieve the effects of saving costs, improving production efficiency, and increasing the number of active lactic acid bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

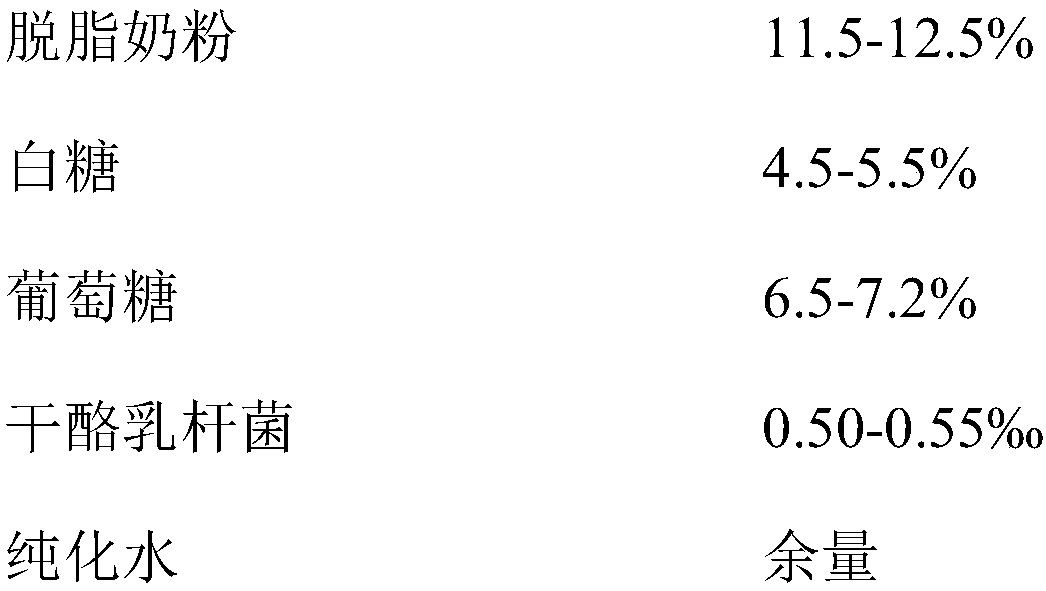

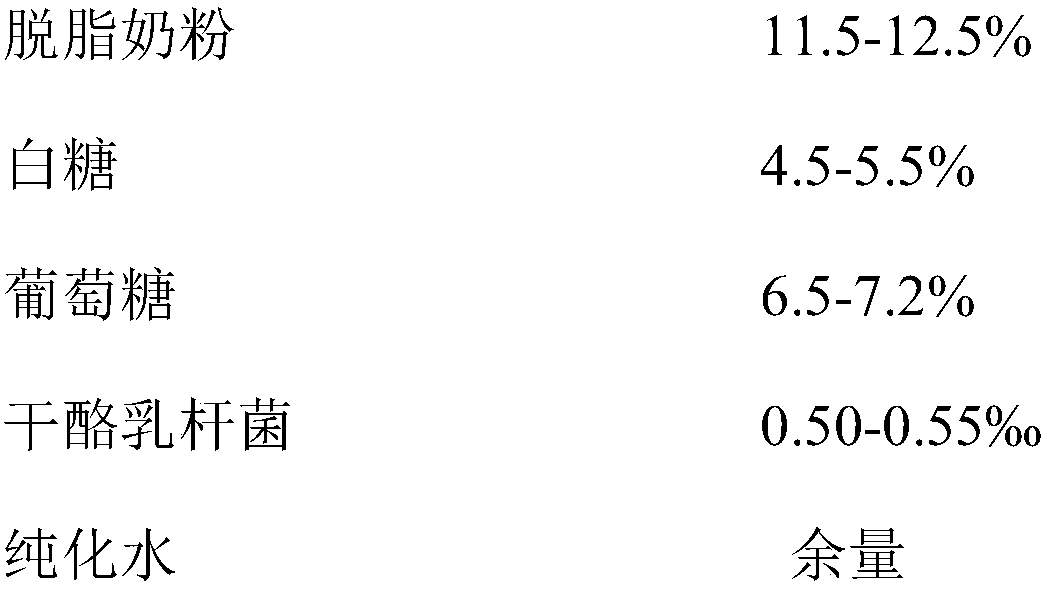

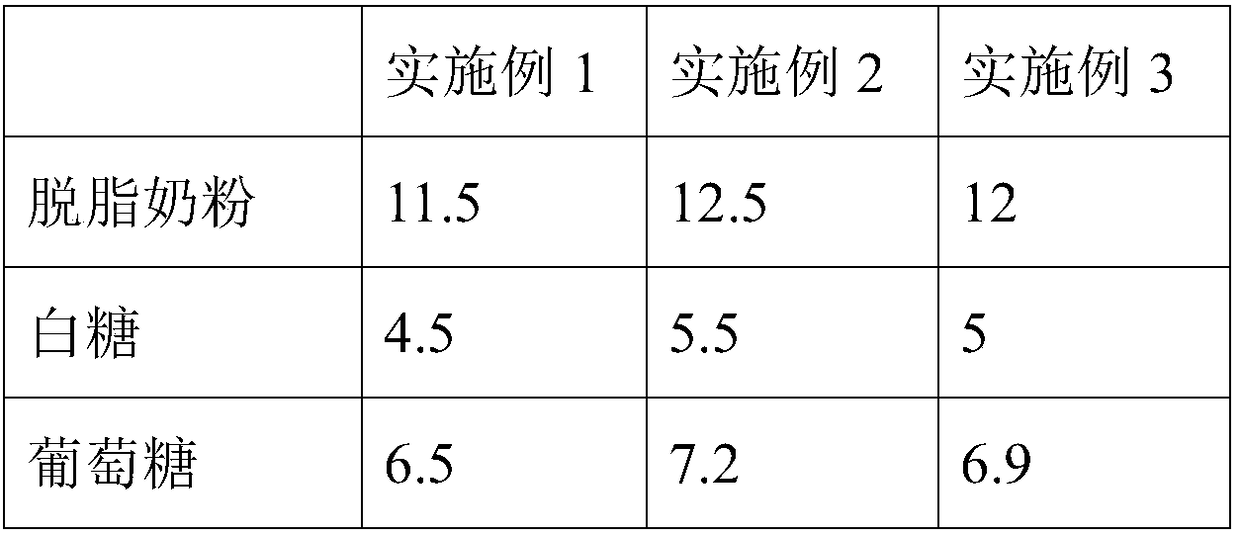

[0056] The probiotic strain preparation of embodiment 1-3, the probiotic strain is obtained by fermentation of the following raw materials in mass percentage:

[0057] Table 1 embodiment 1-3 probiotic strain preparation proportioning

[0058]

[0059]

[0060] The probiotic bacterial strain preparation of embodiment 1-3 all adopts following culture method to carry out, and method comprises,

[0061] Water quality control steps: make drinking water through triple filtration and reverse osmosis system to make purified water, the pH value of purified water is 6.60-6.90;

[0062] Feeding step: heat up the purified water to 50-60°C, then put in skim milk powder, white sugar and glucose, and start the circulation pump to circulate the mixed materials;

[0063] Dissolution step: stop the circulating pump after feeding, stir to fully dissolve the material and recover to obtain milk. During the dissolution step, start stirring once every 20 minutes, stir 3 times in total, each s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com