Closed circulating compressor test bench with helium as working medium

A closed cycle, compressor technology, applied in mechanical equipment, non-variable pumps, machines/engines, etc., to achieve the effects of energy saving, reasonable structural design, and loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

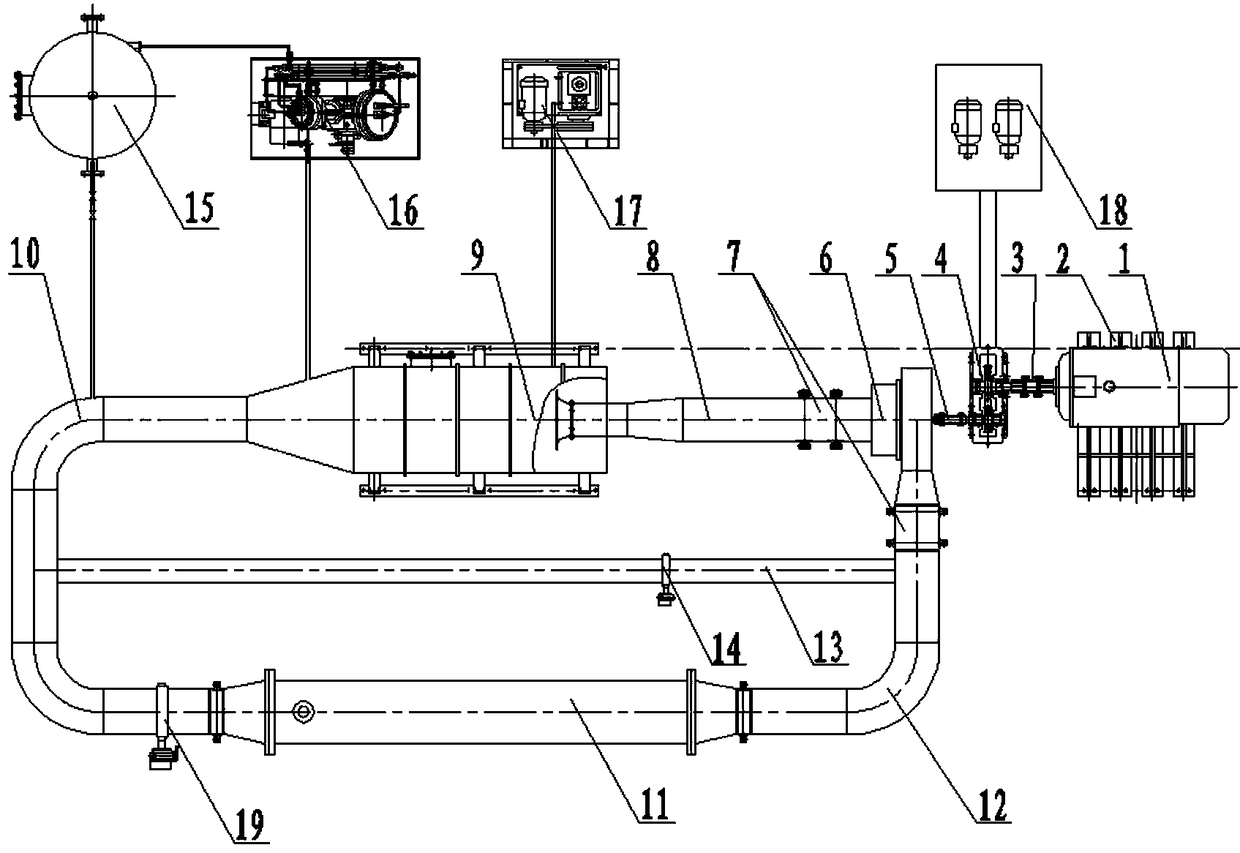

[0022] refer to figure 1 Before the test, the vacuum pump 17 can be used to evacuate the pipeline, and the vacuum situation in the pipeline can be observed through the pressure gauge of the test bench. After the pipeline pressure reaches the requirement, open the valve of the helium gas storage tank 15, Fill helium, observe the pressure gauge in the pipeline again, after reaching the required helium pressure, close the valve of the helium gas storage tank 15, use the motor 1 of the test bench as the power source output, and drive the gear box 4 to accelerate, reaching Meet the speed requirements of the test compressor 6, the test compressor 6 compresses the helium working fluid flowing in from the steady flow section 8, and flows the compressed helium working fluid with high temperature and high pressure along the radial pipeline into the discharge The gas section 12 and the heat exchanger 11 cool down the higher temperature helium working medium until the inlet conditions of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com