Drying technological method with cooling stage and device thereof

A technology of drying equipment and process method, which is applied in the direction of drying, drying machine, lighting and heating equipment, etc. It can solve the problems of uneven drying and wetness, easy yellowing of red pepper, and long time, so as to improve the drying time , maintain the original color and taste, and increase the effect of dehumidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

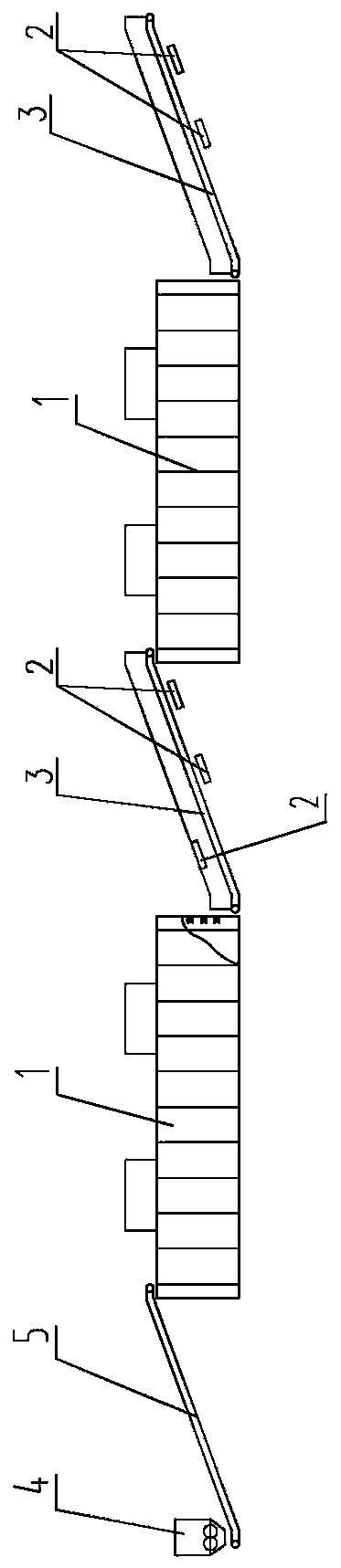

[0020] Example 1, such as figure 1 As shown, the drying process and equipment with its own cooling section include the following steps: feeding, drying, and cooling; repeating drying once or repeating drying and cooling two steps several times or repeating drying, cooling, and drying three times Step several times; after each drying, the difference of the moisture percentage between the inside and outside of the material is not less than 20%, and after each cooling, the difference of the moisture percentage between the inside and the outside of the material is not more than 15%.

[0021] As an optimization of Example 1, the temperature after the first drying of the material is 60°C to 90°C, the moisture percentage inside the material is 40% to 60%, and the moisture percentage outside the material is 20% to 30%; after the material is cooled for the first time The temperature is 30°C to 40°C, the internal moisture percentage of the material is 30% to 40%, the external moisture p...

Embodiment 2

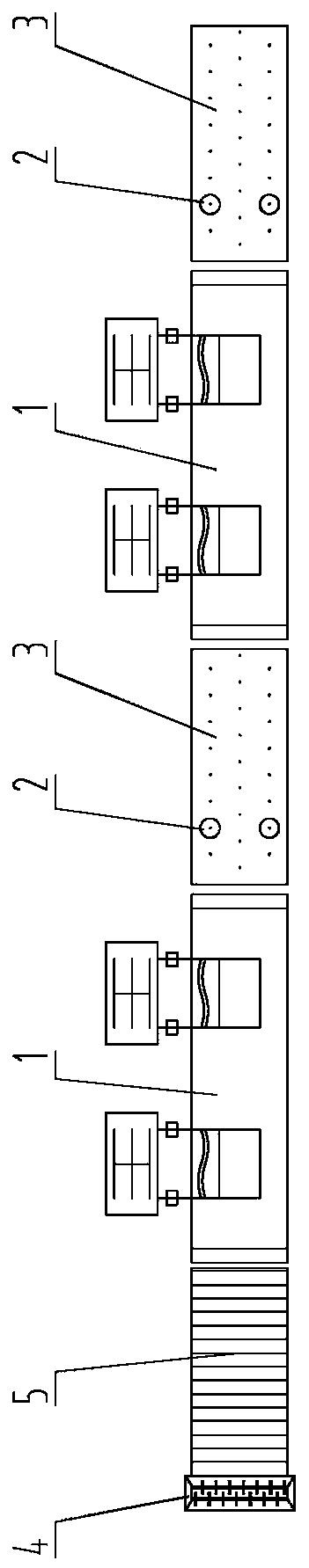

[0027] Example 2, such as figure 1 , 2 As shown, the drying equipment with its own cooling section includes at least one mesh belt dryer 1 and at least one cooler, and the number of coolers is one less than the number of mesh belt dryers 1 or the number of both is equal; The first end is a mesh belt dryer 1, and the mesh belt dryer 1 is connected to the cooler at intervals.

[0028] As an optimization of Example 2, such as figure 1 , 2 As shown, the drying equipment with its own cooling section also includes a distribution machine 4 that can spread the material evenly. The output end of the distribution machine 4 is connected to the input end of the first mesh belt dryer 1 through a conveyor belt 5 . Distributing machine 4 is prior art, and it can evenly spread material on conveyer belt 5, improves drying efficiency.

[0029] As an optimization of Example 2, such as figure 1 , 2 As shown, the cooling machine includes an inclined conveyor belt 5, the input end of the incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com