Image fusion-based metal magnetic material defect detection device

A technology of metal magnetism and material defects, applied in the direction of material magnetic variables, etc., can solve the problems of strong leakage magnetic field signal, weak leakage magnetic field signal, long detection time, etc., to increase penetration depth, eliminate static interference, and enhance magnetic leakage signal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

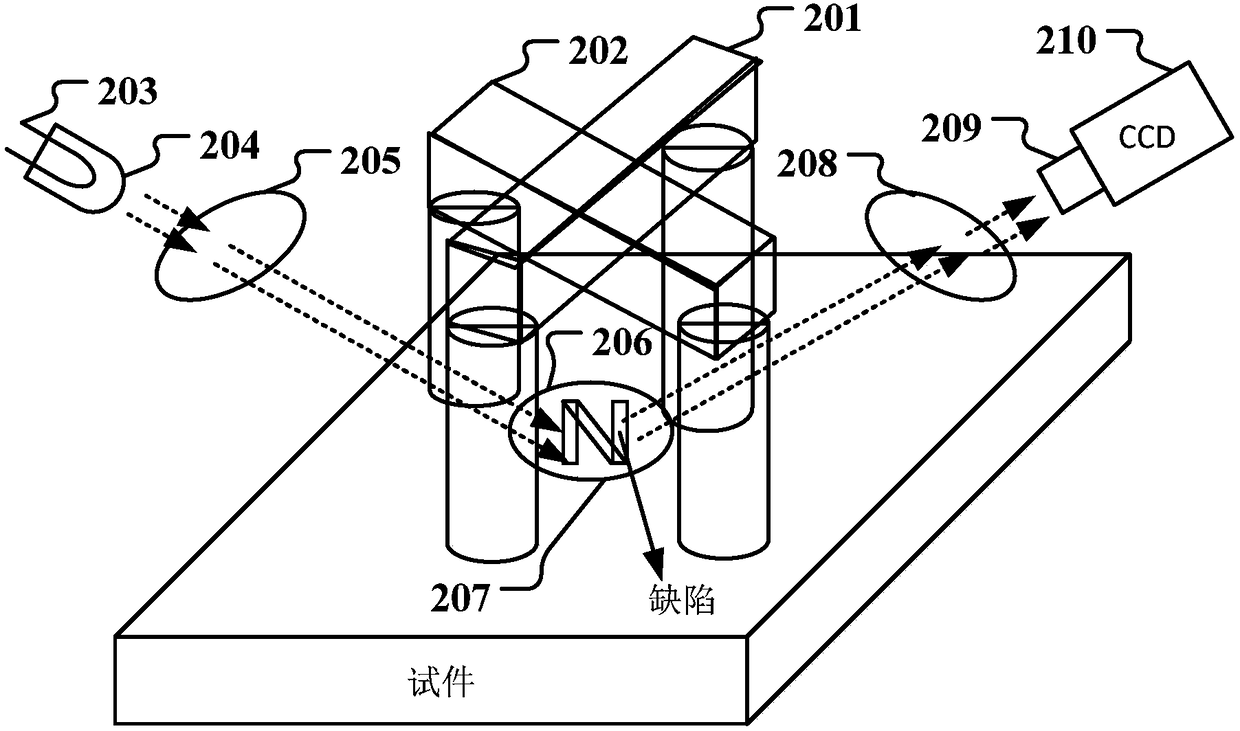

[0027] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention. It should be noted that in the following description, when detailed descriptions of known functions and designs may dilute the main content of the present invention, these descriptions will be omitted here.

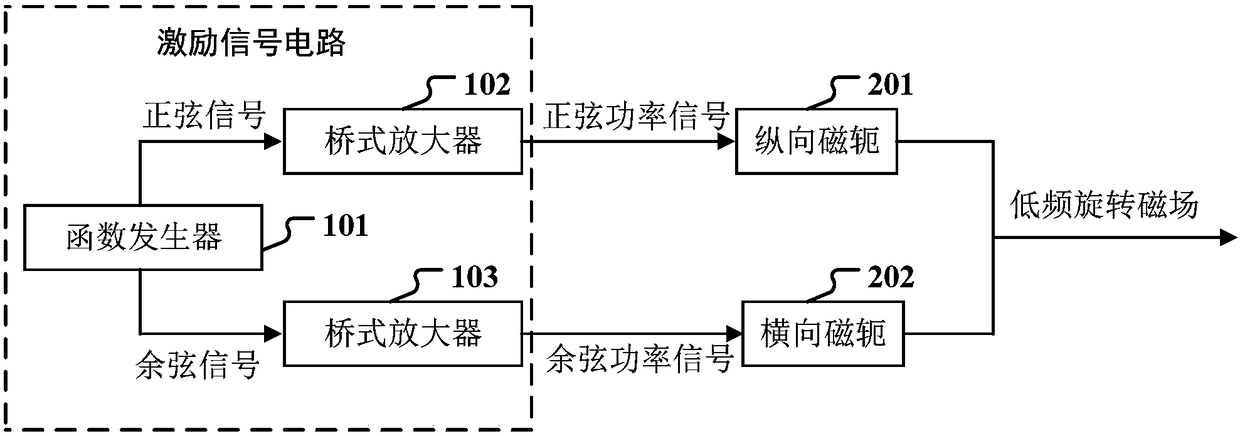

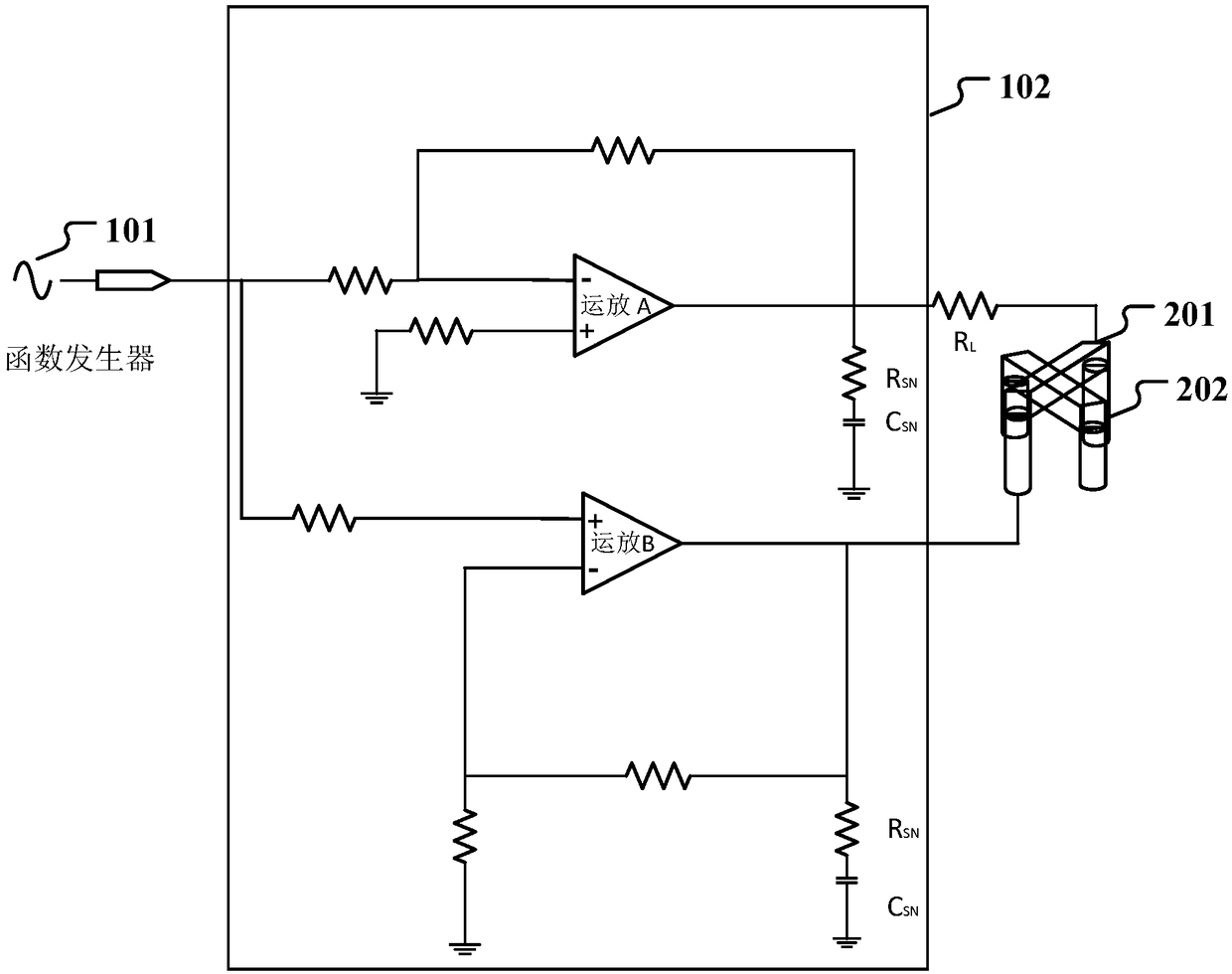

[0028] The metal magnetic material defect detection device based on image fusion of the present invention is divided into a hardware module and a software module, wherein the hardware module includes an excitation signal circuit and a magneto-optical imaging system, and the software module includes a fusion algorithm module. Each module will be described in detail below in conjunction with the accompanying drawings

[0029] 1. Exciting signal circuit

[0030] In this example, if figure 1 As shown, the excitation signal circuit includes a function generator 101 and two bri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com