A Magnetically Coupled Non-Resonant Rotating Piezoelectric Generator

A non-resonant, rotary pressure technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of low frequency modulation ability, difficult precise control, low power generation efficiency, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

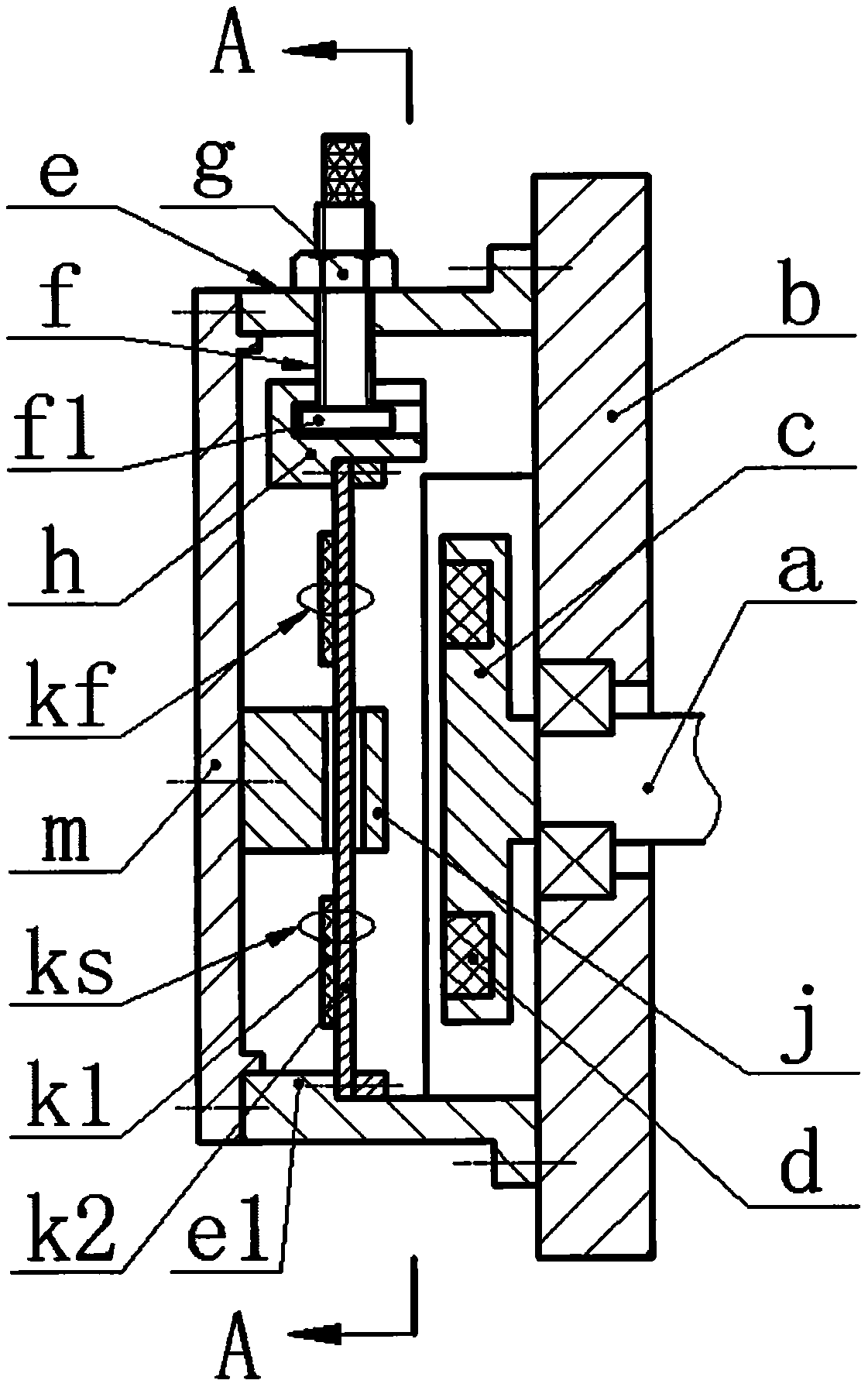

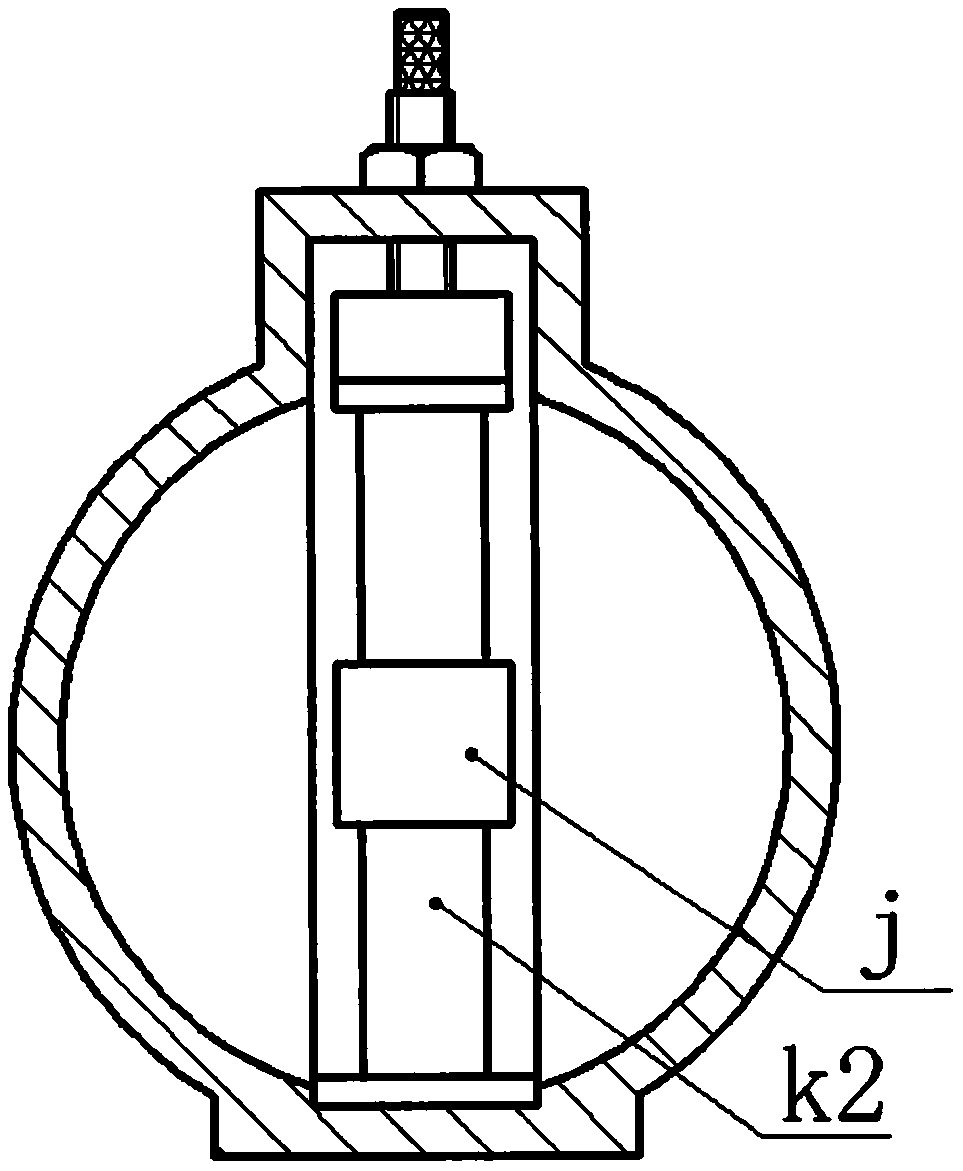

[0016] The rotating shaft a is installed on the bottom shell b via a bearing, and a turntable c is installed at the end, and the end surface of the turntable c is uniformly inlaid with excitation magnets d; the right flange end of the shell e is installed on the bottom shell b via screws, The left side is equipped with an end cover m through screws; the top of the shell e is provided with a threaded hole, and the inside is provided with a boss e1; the adjusting bolt f protrudes from the inside of the shell e through the threaded hole, and a lock nut g is screwed on the outside; The bottom of the adjusting bolt f is provided with a circular boss f1, and the circular boss f1 extends into the gap of the loading block h; the two ends of the ferromagnetic substrate k1 are respectively installed on the loading block h and the boss e1 through screws and pressure blocks, and the middle part Its lateral displacement is constrained by the guide block j with a gap, and thus divided into u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com