Optimizing design method of two-phase low temperature liquid expansion machine cavitation resistance

A low-temperature liquid, optimized design technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as public reports on the anti-cavitation technology of two-phase liquid expanders, and achieve improved performance and operational stability. Avoid vibration and downtime as well as the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in further detail below in conjunction with accompanying drawing:

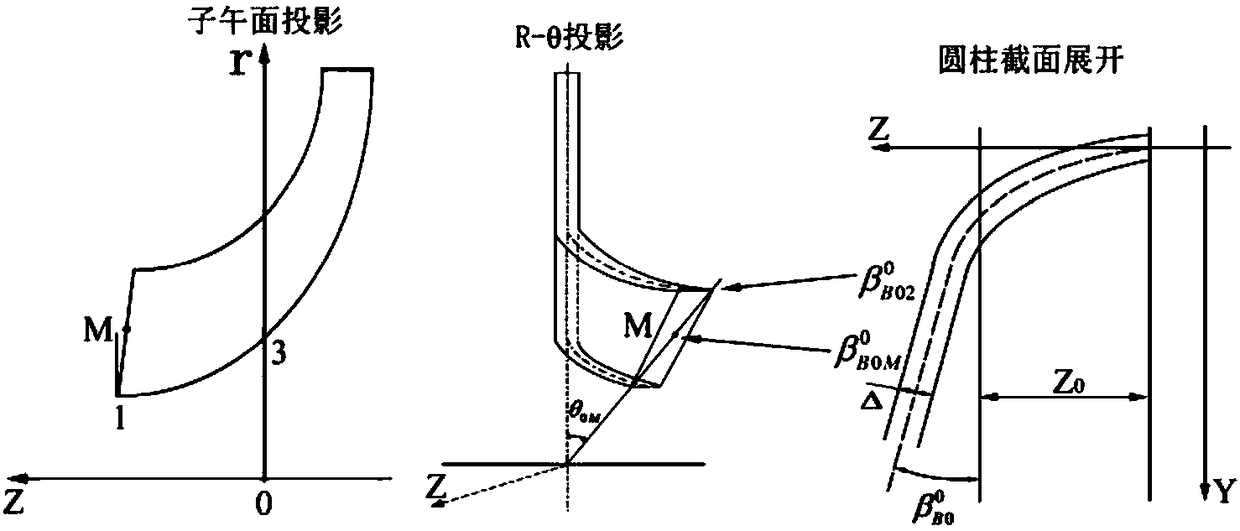

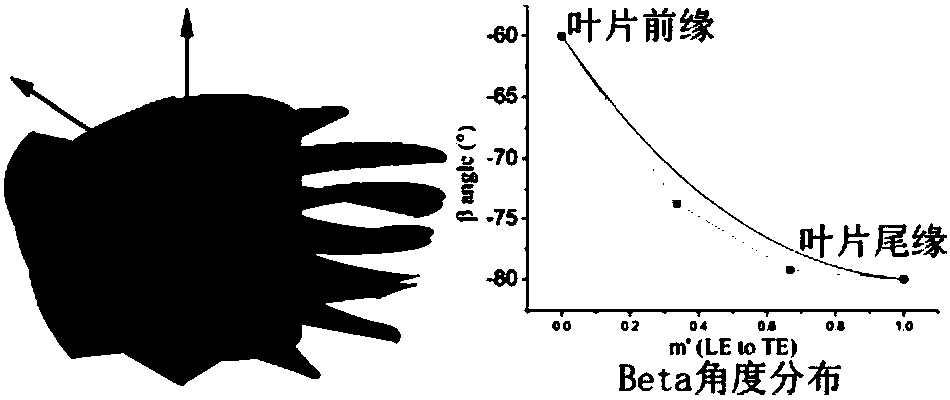

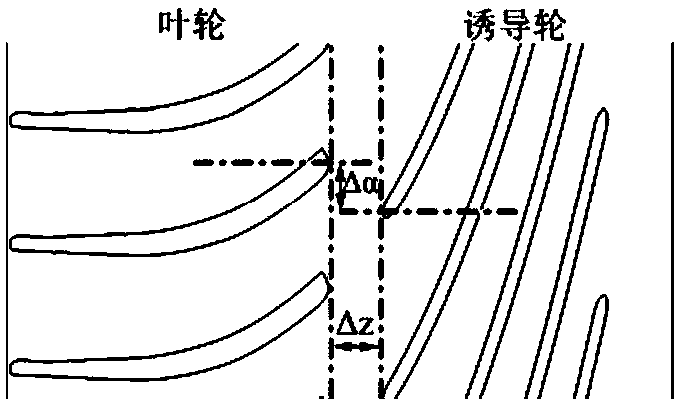

[0030] The anti-cavitation optimization design method of the two-phase low-temperature liquid expander of the present invention includes the research on the vortex cavitation mechanism of the two-phase low-temperature liquid expander considering the thermodynamic effect of the low-temperature fluid, the geometry of the vortex cavitation flow in the two-phase low-temperature liquid expander Parameter sensitivity analysis, characterization of complex vortex cavitation flow in two-phase cryogenic liquid expander, construction of flow field optimization objective function for controlling vortex cavitation flow, optimal control of vortex cavitation flow and anti-cavitation Parallel solution of optimization design problems.

[0031]1. Research on the vortex cavitation mechanism of two-phase cryogenic liquid expander considering the thermodynamic effect of cryogenic fluid

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com